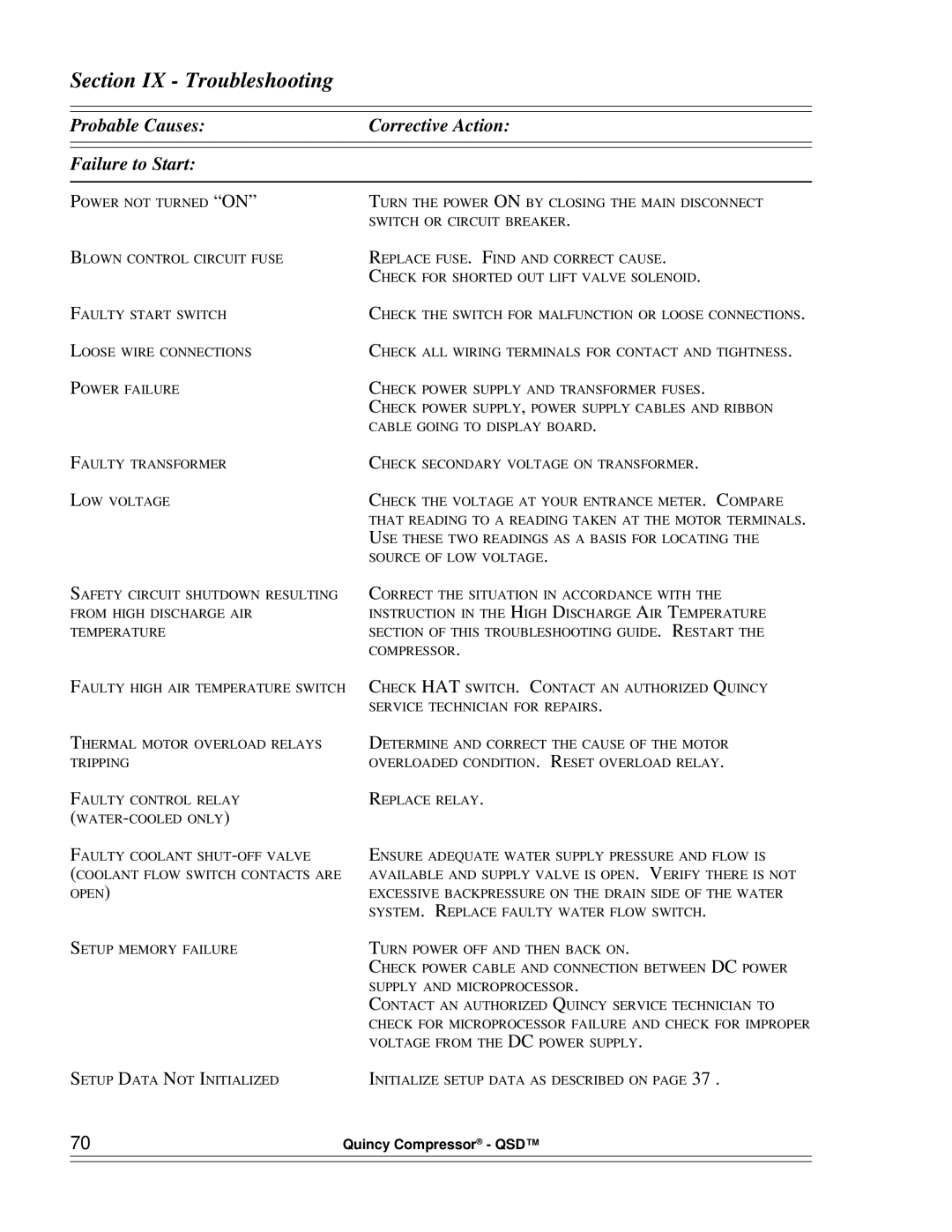

Section IX - Troubleshooting

Probable Causes: | Corrective Action: |

|

|

Failure to Start: |

|

|

|

POWER NOT TURNED “ON” | TURN THE POWER ON BY CLOSING THE MAIN DISCONNECT |

| SWITCH OR CIRCUIT BREAKER. |

BLOWN CONTROL CIRCUIT FUSE | REPLACE FUSE. FIND AND CORRECT CAUSE. |

| CHECK FOR SHORTED OUT LIFT VALVE SOLENOID. |

FAULTY START SWITCH | CHECK THE SWITCH FOR MALFUNCTION OR LOOSE CONNECTIONS. |

LOOSE WIRE CONNECTIONS | CHECK ALL WIRING TERMINALS FOR CONTACT AND TIGHTNESS. |

POWER FAILURE | CHECK POWER SUPPLY AND TRANSFORMER FUSES. |

| CHECK POWER SUPPLY, POWER SUPPLY CABLES AND RIBBON |

| CABLE GOING TO DISPLAY BOARD. |

FAULTY TRANSFORMER | CHECK SECONDARY VOLTAGE ON TRANSFORMER. |

LOW VOLTAGE | CHECK THE VOLTAGE AT YOUR ENTRANCE METER. COMPARE |

| THAT READING TO A READING TAKEN AT THE MOTOR TERMINALS. |

| USE THESE TWO READINGS AS A BASIS FOR LOCATING THE |

| SOURCE OF LOW VOLTAGE. |

SAFETY CIRCUIT SHUTDOWN RESULTING FROM HIGH DISCHARGE AIR TEMPERATURE

FAULTY HIGH AIR TEMPERATURE SWITCH

THERMAL MOTOR OVERLOAD RELAYS

TRIPPING

FAULTY CONTROL RELAY

FAULTY COOLANT

(COOLANT FLOW SWITCH CONTACTS ARE

OPEN)

SETUP MEMORY FAILURE

SETUP DATA NOT INITIALIZED

CORRECT THE SITUATION IN ACCORDANCE WITH THE INSTRUCTION IN THE HIGH DISCHARGE AIR TEMPERATURE SECTION OF THIS TROUBLESHOOTING GUIDE. RESTART THE COMPRESSOR.

CHECK HAT SWITCH. CONTACT AN AUTHORIZED QUINCY SERVICE TECHNICIAN FOR REPAIRS.

DETERMINE AND CORRECT THE CAUSE OF THE MOTOR OVERLOADED CONDITION. RESET OVERLOAD RELAY.

REPLACE RELAY.

ENSURE ADEQUATE WATER SUPPLY PRESSURE AND FLOW IS AVAILABLE AND SUPPLY VALVE IS OPEN. VERIFY THERE IS NOT EXCESSIVE BACKPRESSURE ON THE DRAIN SIDE OF THE WATER SYSTEM. REPLACE FAULTY WATER FLOW SWITCH.

TURN POWER OFF AND THEN BACK ON.

CHECK POWER CABLE AND CONNECTION BETWEEN DC POWER SUPPLY AND MICROPROCESSOR.

CONTACT AN AUTHORIZED QUINCY SERVICE TECHNICIAN TO CHECK FOR MICROPROCESSOR FAILURE AND CHECK FOR IMPROPER VOLTAGE FROM THE DC POWER SUPPLY.

INITIALIZE SETUP DATA AS DESCRIBED ON PAGE 37 .

70 | Quincy Compressor® - QSD™ |

|

|