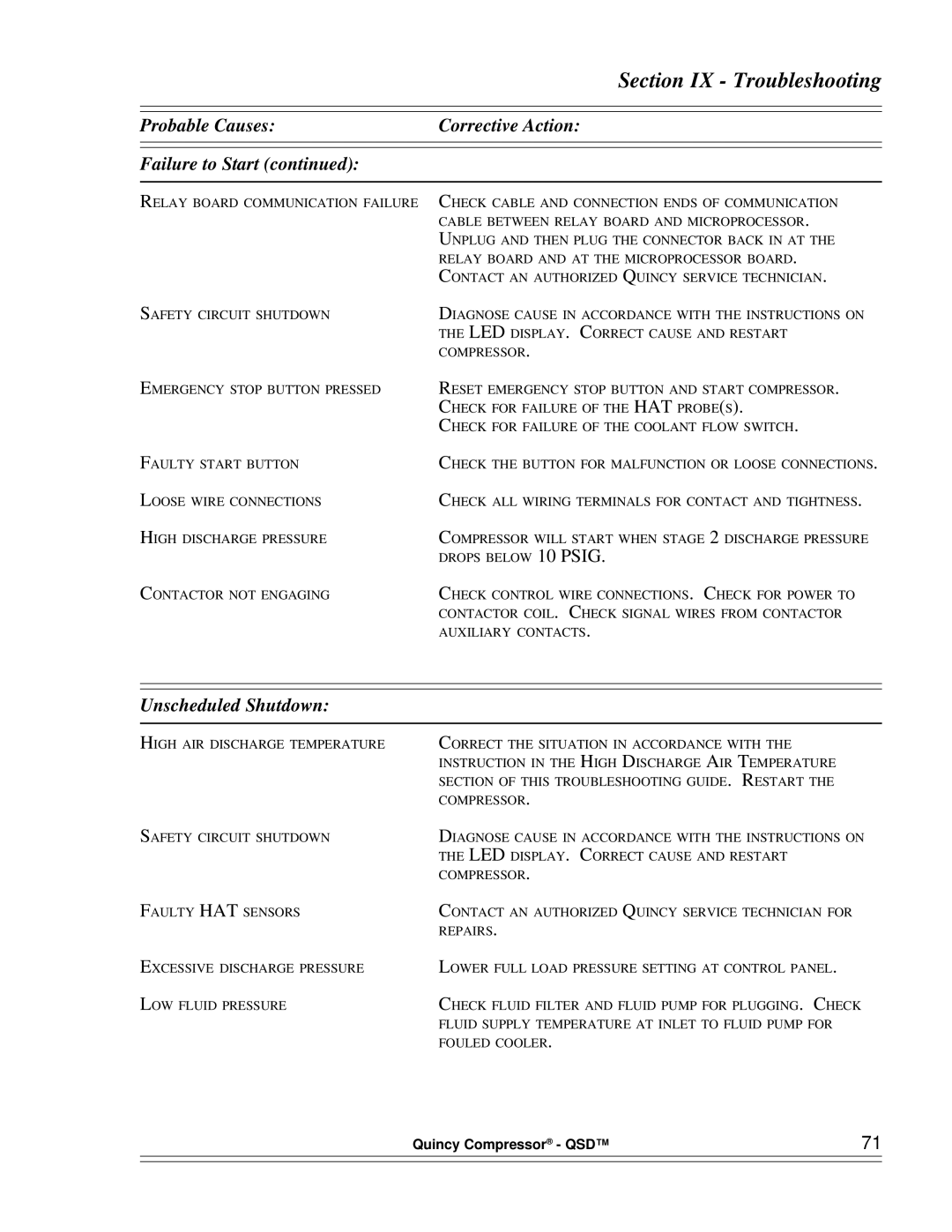

| Section IX - Troubleshooting |

|

|

|

|

Probable Causes: | Corrective Action: |

|

|

|

|

Failure to Start (continued): |

|

|

|

RELAY BOARD COMMUNICATION FAILURE | CHECK CABLE AND CONNECTION ENDS OF COMMUNICATION |

| CABLE BETWEEN RELAY BOARD AND MICROPROCESSOR. |

| UNPLUG AND THEN PLUG THE CONNECTOR BACK IN AT THE |

| RELAY BOARD AND AT THE MICROPROCESSOR BOARD. |

| CONTACT AN AUTHORIZED QUINCY SERVICE TECHNICIAN. |

SAFETY CIRCUIT SHUTDOWN | DIAGNOSE CAUSE IN ACCORDANCE WITH THE INSTRUCTIONS ON |

| THE LED DISPLAY. CORRECT CAUSE AND RESTART |

| COMPRESSOR. |

EMERGENCY STOP BUTTON PRESSED | RESET EMERGENCY STOP BUTTON AND START COMPRESSOR. |

| CHECK FOR FAILURE OF THE HAT PROBE(S). |

| CHECK FOR FAILURE OF THE COOLANT FLOW SWITCH. |

FAULTY START BUTTON | CHECK THE BUTTON FOR MALFUNCTION OR LOOSE CONNECTIONS. |

LOOSE WIRE CONNECTIONS | CHECK ALL WIRING TERMINALS FOR CONTACT AND TIGHTNESS. |

HIGH DISCHARGE PRESSURE | COMPRESSOR WILL START WHEN STAGE 2 DISCHARGE PRESSURE |

| DROPS BELOW 10 PSIG. |

CONTACTOR NOT ENGAGING | CHECK CONTROL WIRE CONNECTIONS. CHECK FOR POWER TO |

| CONTACTOR COIL. CHECK SIGNAL WIRES FROM CONTACTOR |

| AUXILIARY CONTACTS. |

|

|

|

|

Unscheduled Shutdown: |

|

|

|

HIGH AIR DISCHARGE TEMPERATURE | CORRECT THE SITUATION IN ACCORDANCE WITH THE |

| INSTRUCTION IN THE HIGH DISCHARGE AIR TEMPERATURE |

| SECTION OF THIS TROUBLESHOOTING GUIDE. RESTART THE |

| COMPRESSOR. |

SAFETY CIRCUIT SHUTDOWN | DIAGNOSE CAUSE IN ACCORDANCE WITH THE INSTRUCTIONS ON |

| THE LED DISPLAY. CORRECT CAUSE AND RESTART |

| COMPRESSOR. |

FAULTY HAT SENSORS | CONTACT AN AUTHORIZED QUINCY SERVICE TECHNICIAN FOR |

| REPAIRS. |

EXCESSIVE DISCHARGE PRESSURE | LOWER FULL LOAD PRESSURE SETTING AT CONTROL PANEL. |

LOW FLUID PRESSURE | CHECK FLUID FILTER AND FLUID PUMP FOR PLUGGING. CHECK |

| FLUID SUPPLY TEMPERATURE AT INLET TO FLUID PUMP FOR |

| FOULED COOLER. |

Quincy Compressor® - QSD™ | 71 |

|

|