OPERATION

These rotary hammers have an Electronic Feedback Control Circuit (EFCC) which helps improve the operation and life of the tool.

Soft Start

The

Feedback Control

The electronic speed control system allows the tool to maintain constant speed and torque between

![]() WARNING!

WARNING!

To reduce the risk of injury, wear safety goggles or glasses with side shields. Unplug the tool before changing accesso- ries or making adjustments.

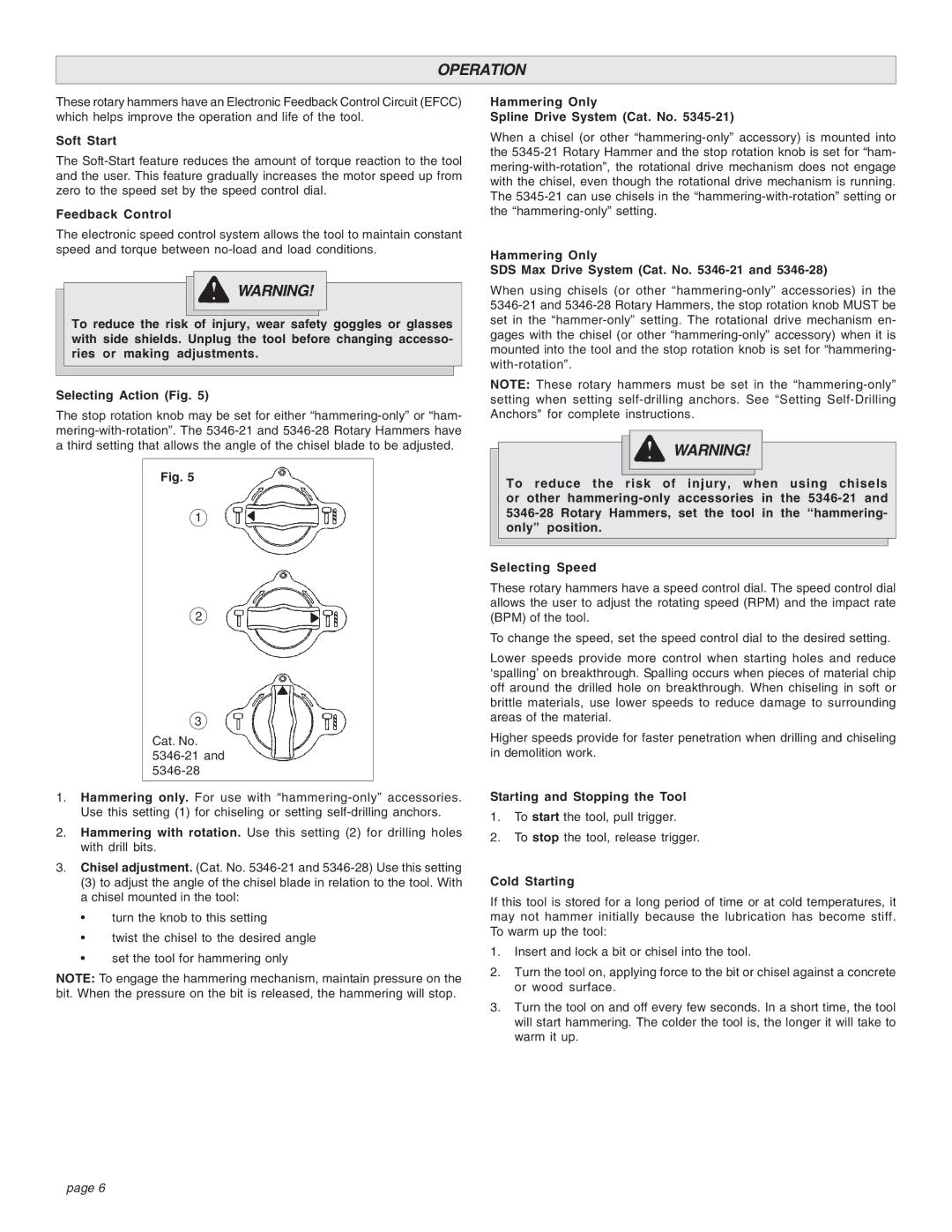

Selecting Action (Fig. 5)

The stop rotation knob may be set for either

Fig. 5

1

2

3

Cat. No.

1.Hammering only. For use with

2.Hammering with rotation. Use this setting (2) for drilling holes with drill bits.

3.Chisel adjustment. (Cat. No.

(3) to adjust the angle of the chisel blade in relation to the tool. With a chisel mounted in the tool:

•turn the knob to this setting

•twist the chisel to the desired angle

•set the tool for hammering only

NOTE: To engage the hammering mechanism, maintain pressure on the bit. When the pressure on the bit is released, the hammering will stop.

Hammering Only

Spline Drive System (Cat. No. 5345-21)

When a chisel (or other

Hammering Only

SDS Max Drive System (Cat. No. 5346-21 and 5346-28)

When using chisels (or other

NOTE: These rotary hammers must be set in the

![]() WARNING!

WARNING!

To reduce the risk of injury, when using chisels or other

Selecting Speed

These rotary hammers have a speed control dial. The speed control dial allows the user to adjust the rotating speed (RPM) and the impact rate (BPM) of the tool.

To change the speed, set the speed control dial to the desired setting.

Lower speeds provide more control when starting holes and reduce ‘spalling’ on breakthrough. Spalling occurs when pieces of material chip off around the drilled hole on breakthrough. When chiseling in soft or brittle materials, use lower speeds to reduce damage to surrounding areas of the material.

Higher speeds provide for faster penetration when drilling and chiseling in demolition work.

Starting and Stopping the Tool

1.To start the tool, pull trigger.

2.To stop the tool, release trigger.

Cold Starting

If this tool is stored for a long period of time or at cold temperatures, it may not hammer initially because the lubrication has become stiff. To warm up the tool:

1.Insert and lock a bit or chisel into the tool.

2.Turn the tool on, applying force to the bit or chisel against a concrete or wood surface.

3.Turn the tool on and off every few seconds. In a short time, the tool will start hammering. The colder the tool is, the longer it will take to warm it up.

page 6