TOOL ASSEMBLY

![]()

![]()

![]() WARNING!

WARNING!

Wear safety goggles or glasses with side shields. Always unplug tool before attaching or removing accessories. Only use accessories specifically recommended for these tools. Others may be hazardous. Protect others in work area from debris such as chips and sparks. Provide barriers or shields as needed.

Removing and Replacing

MILWAUKEE's exclusive

Fig. 1

1.To remove the

2.To replace the

Installing Side Handle

The side handle may be installed on the top of the gear case or on either side of gear case for right or left handed use. Position side handle in the location which offers best control and guard protection. To install, thread side handle into side handle socket on desired side of gear case and tighten securely.

OPERATION

![]()

![]()

![]() WARNING!

WARNING!

To reduce the risk of injury, wear safety goggles or glasses with side shields. Unplug the tool before changing accesso- ries or making adjustments.

Controlled Start (Cat. No.

When used on 120 Volts AC, the controlled start feature reduces the torque reaction "jerk" when its trigger is pulled. The controlled start feature works only with AC.

Speed Control Dial (Cat. No. 6154-20 and 6156-20)

The speed control dial controls the sander/grinder's maximum rotations per minute. Dial settings range from numbers 1 through 5. Lower num- bers correspond to lower speeds and higher numbers correspond to higher speeds. Use the setting that best suits your job.

1.To control the speed, set the dial to the desired number.

2.Pull the trigger.

3.To stop the tool, release the trigger.

Constant Speed Tachometer (Cat. No. 6160-20)

The constant speed tachometer, which keeps the tool's revolutions per minute (9000 RPM) at an almost constant speed even under load. The tachometer also helps prevent tool overheating. The tool switches itself off automatically when the motor is overloaded. It can be restarted by squeezing the paddle trigger again.

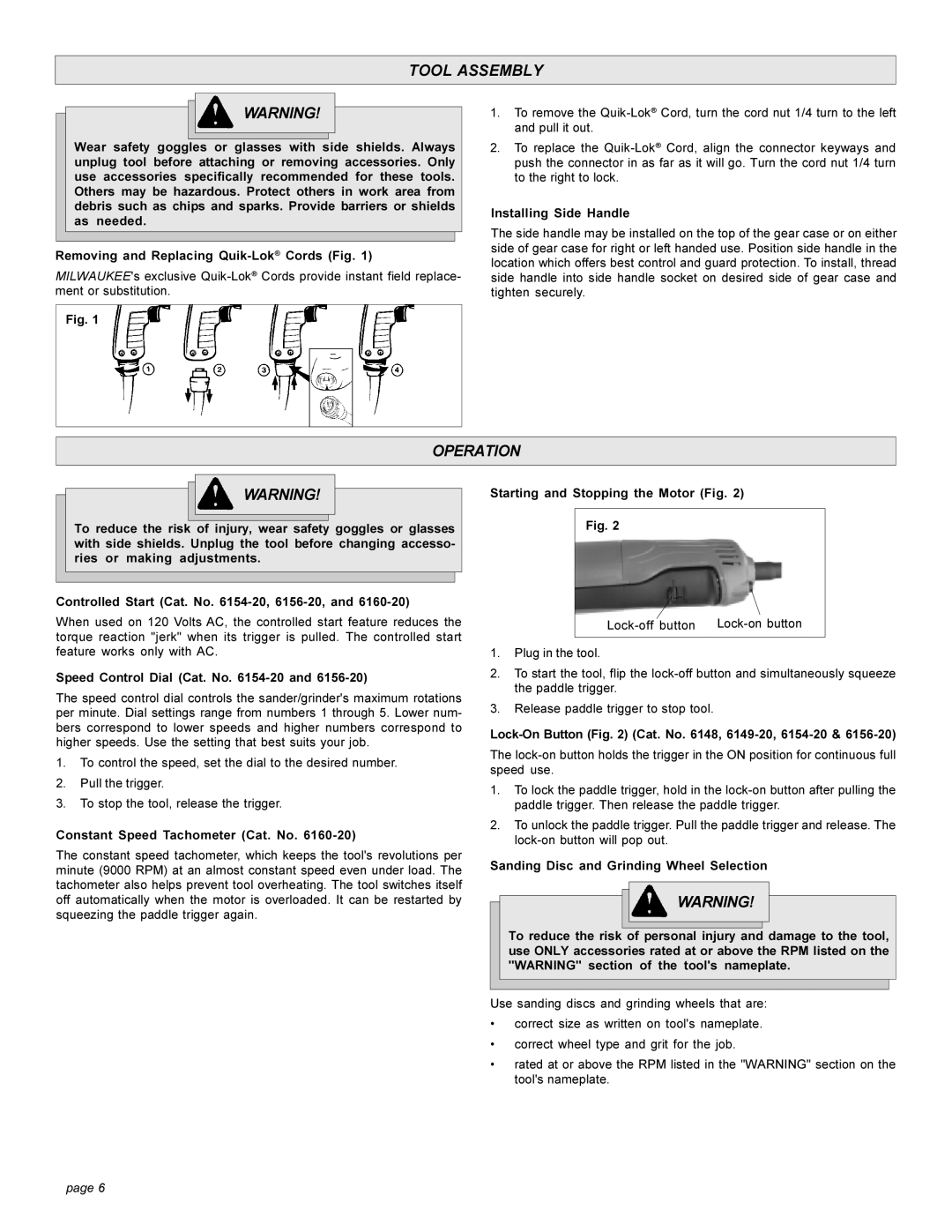

Starting and Stopping the Motor (Fig. 2)

Fig. 2

1.Plug in the tool.

2.To start the tool, flip the

3.Release paddle trigger to stop tool.

Lock-On Button (Fig. 2) (Cat. No. 6148, 6149-20, 6154-20 & 6156-20)

The

1.To lock the paddle trigger, hold in the

2.To unlock the paddle trigger. Pull the paddle trigger and release. The

Sanding Disc and Grinding Wheel Selection

![]()

![]()

![]() WARNING!

WARNING!

To reduce the risk of personal injury and damage to the tool, use ONLY accessories rated at or above the RPM listed on the "WARNING" section of the tool's nameplate.

Use sanding discs and grinding wheels that are:

•correct size as written on tool's nameplate.

•correct wheel type and grit for the job.

•rated at or above the RPM listed in the "WARNING" section on the tool's nameplate.

page 6