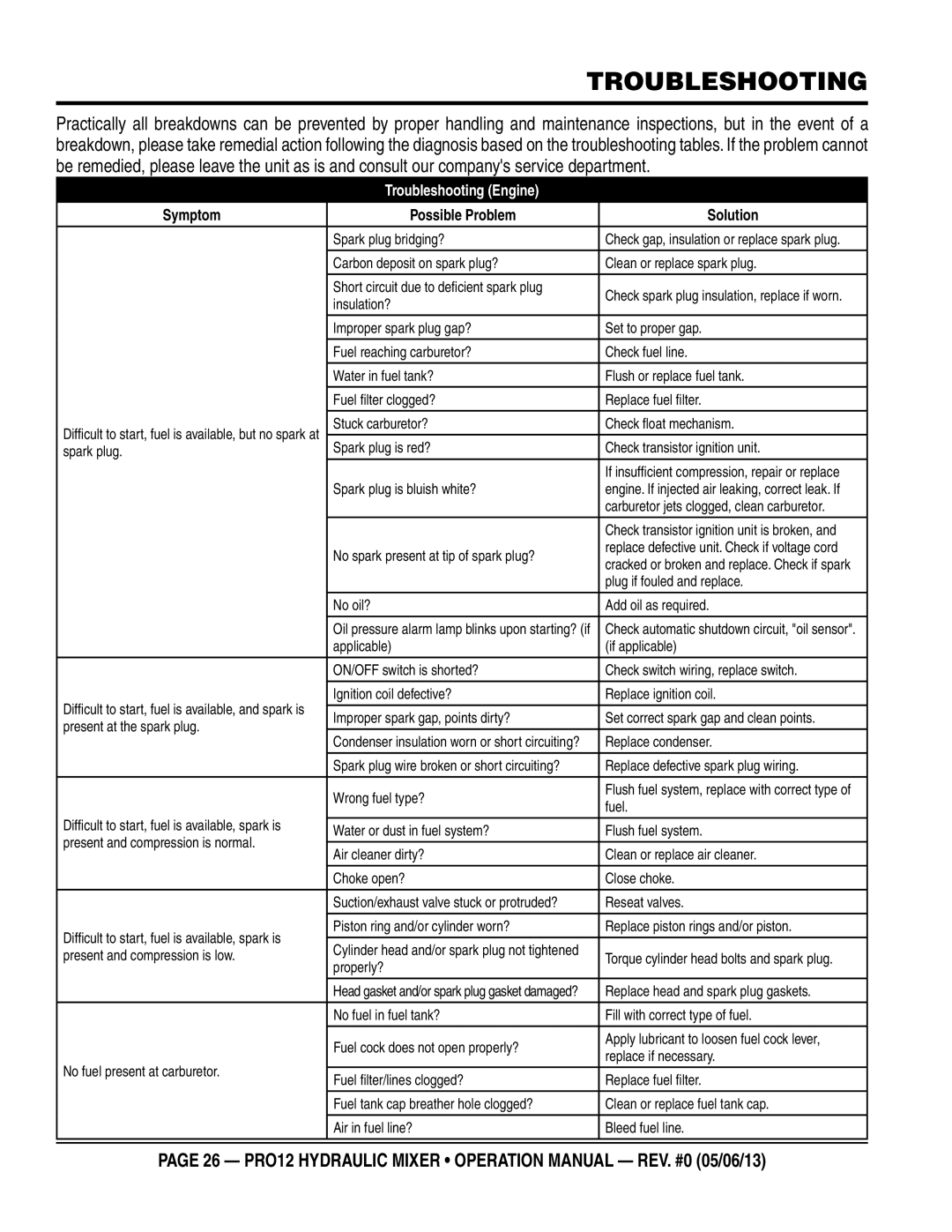

troubleshooting

Practically all breakdowns can be prevented by proper handling and maintenance inspections, but in the event of a breakdown, please take remedial action following the diagnosis based on the troubleshooting tables. If the problem cannot be remedied, please leave the unit as is and consult our company's service department.

troubleshooting (engine)

Symptom | Possible Problem | Solution | |

| Spark plug bridging? | Check gap, insulation or replace spark plug. | |

|

|

| |

| Carbon deposit on spark plug? | Clean or replace spark plug. | |

|

|

| |

| Short circuit due to defi cient spark plug | Check spark plug insulation, replace if worn. | |

| insulation? | ||

|

| ||

|

|

| |

| Improper spark plug gap? | Set to proper gap. | |

|

|

| |

| Fuel reaching carburetor? | Check fuel line. | |

| Water in fuel tank? | Flush or replace fuel tank. | |

|

|

| |

| Fuel fi lter clogged? | Replace fuel fi lter. | |

Diffi cult to start, fuel is available, but no spark at | Stuck carburetor? | Check fl oat mechanism. | |

|

| ||

Spark plug is red? | Check transistor ignition unit. | ||

spark plug. | |||

|

| If insuffi cient compression, repair or replace | |

| Spark plug is bluish white? | engine. If injected air leaking, correct leak. If | |

|

| carburetor jets clogged, clean carburetor. | |

|

|

| |

|

| Check transistor ignition unit is broken, and | |

| No spark present at tip of spark plug? | replace defective unit. Check if voltage cord | |

| cracked or broken and replace. Check if spark | ||

|

| ||

|

| plug if fouled and replace. | |

|

|

| |

| No oil? | Add oil as required. | |

|

|

| |

| Oil pressure alarm lamp blinks upon starting? (if | Check automatic shutdown circuit, "oil sensor". | |

| applicable) | (if applicable) | |

|

|

| |

| ON/OFF switch is shorted? | Check switch wiring, replace switch. | |

|

|

| |

Diffi cult to start, fuel is available, and spark is | Ignition coil defective? | Replace ignition coil. | |

|

| ||

Improper spark gap, points dirty? | Set correct spark gap and clean points. | ||

present at the spark plug. | |||

|

| ||

Condenser insulation worn or short circuiting? | Replace condenser. | ||

| |||

|

|

| |

| Spark plug wire broken or short circuiting? | Replace defective spark plug wiring. | |

|

|

| |

| Wrong fuel type? | Flush fuel system, replace with correct type of | |

| fuel. | ||

|

| ||

Diffi cult to start, fuel is available, spark is | Water or dust in fuel system? | Flush fuel system. | |

present and compression is normal. | |||

|

| ||

Air cleaner dirty? | Clean or replace air cleaner. | ||

| |||

|

|

| |

| Choke open? | Close choke. | |

|

|

| |

| Suction/exhaust valve stuck or protruded? | Reseat valves. | |

|

|

| |

Diffi cult to start, fuel is available, spark is | Piston ring and/or cylinder worn? | Replace piston rings and/or piston. | |

|

| ||

Cylinder head and/or spark plug not tightened |

| ||

present and compression is low. | Torque cylinder head bolts and spark plug. | ||

properly? | |||

|

| ||

|

|

| |

| Head gasket and/or spark plug gasket damaged? | Replace head and spark plug gaskets. | |

| No fuel in fuel tank? | Fill with correct type of fuel. | |

|

|

| |

| Fuel cock does not open properly? | Apply lubricant to loosen fuel cock lever, | |

| replace if necessary. | ||

No fuel present at carburetor. |

| ||

|

| ||

Fuel fi lter/lines clogged? | Replace fuel fi lter. | ||

| |||

|

|

| |

| Fuel tank cap breather hole clogged? | Clean or replace fuel tank cap. | |

|

|

| |

| Air in fuel line? | Bleed fuel line. | |

|

|

| |

|

|

|

page 26 — Pro12 hydraulic mixer • operation manual — rev. #0 (05/06/13)