CAUTION: Ensure that the actuator arm is not bent during reassembly.

10.With the DVO aligned over the hex on the LS200NDVO body, tighten the valve using the 9/16” hex wrench. You may need to hold the DVO while tightening to keep it from rotating.

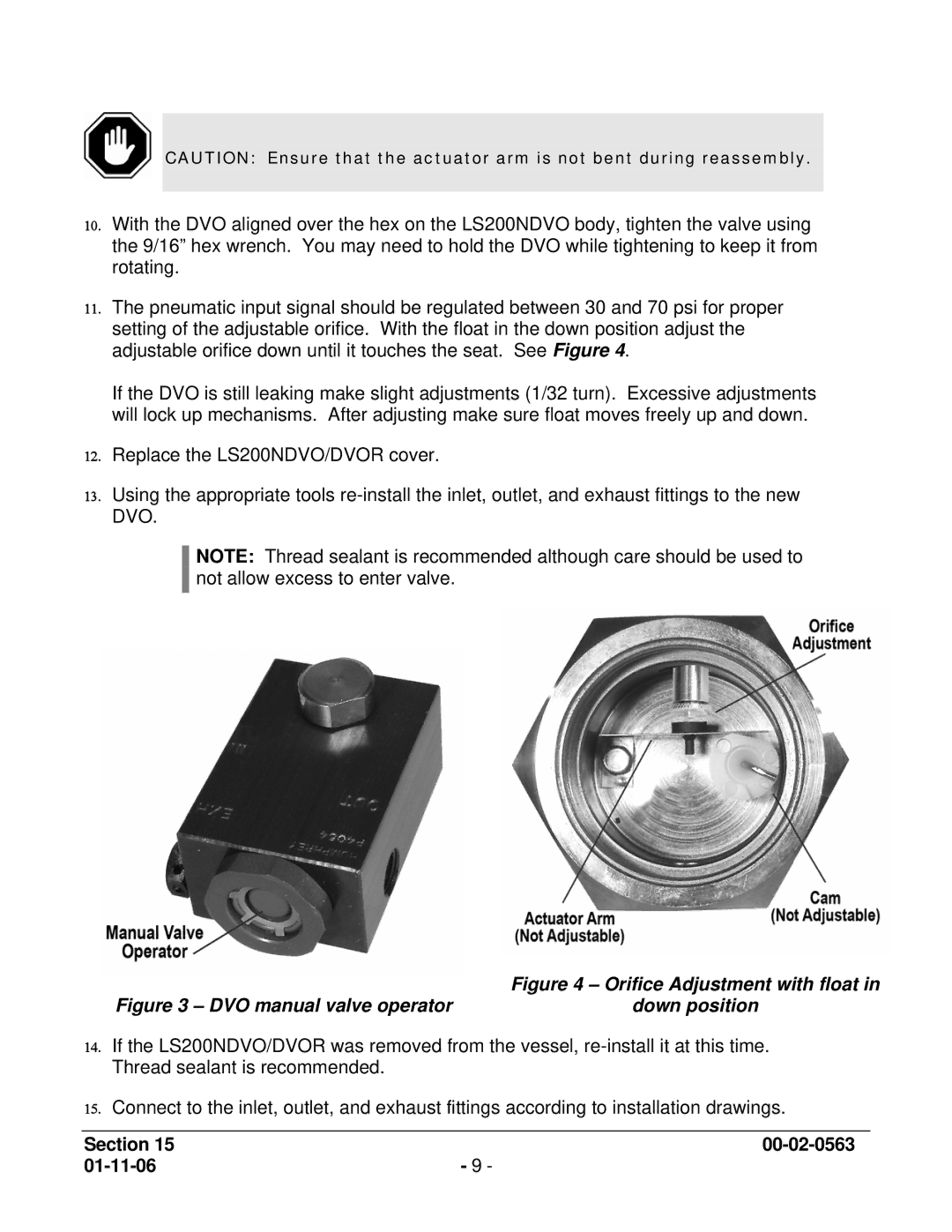

11.The pneumatic input signal should be regulated between 30 and 70 psi for proper setting of the adjustable orifice. With the float in the down position adjust the adjustable orifice down until it touches the seat. See Figure 4.

If the DVO is still leaking make slight adjustments (1/32 turn). Excessive adjustments will lock up mechanisms. After adjusting make sure float moves freely up and down.

12.Replace the LS200NDVO/DVOR cover.

13.Using the appropriate tools

NOTE: Thread sealant is recommended although care should be used to not allow excess to enter valve.

| Figure 4 – Orifice Adjustment with float in |

Figure 3 – DVO manual valve operator | down position |

14.If the LS200NDVO/DVOR was removed from the vessel,

15.Connect to the inlet, outlet, and exhaust fittings according to installation drawings.

Section 15 | |

- 9 - |