E.CONNECTING NOZZLES

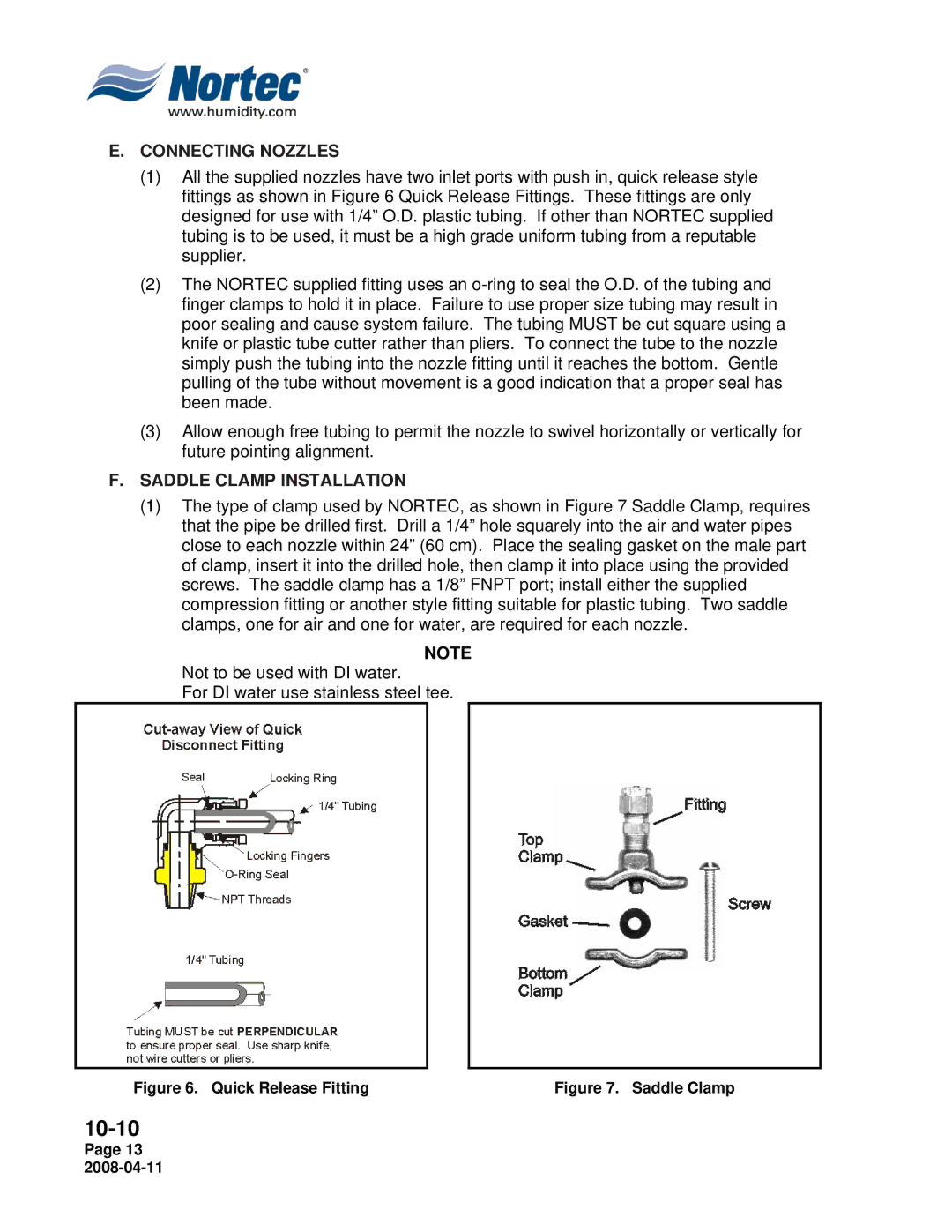

(1)All the supplied nozzles have two inlet ports with push in, quick release style fittings as shown in Figure 6 Quick Release Fittings. These fittings are only designed for use with 1/4” O.D. plastic tubing. If other than NORTEC supplied tubing is to be used, it must be a high grade uniform tubing from a reputable supplier.

(2)The NORTEC supplied fitting uses an

(3)Allow enough free tubing to permit the nozzle to swivel horizontally or vertically for future pointing alignment.

F.SADDLE CLAMP INSTALLATION

(1)The type of clamp used by NORTEC, as shown in Figure 7 Saddle Clamp, requires that the pipe be drilled first. Drill a 1/4” hole squarely into the air and water pipes close to each nozzle within 24” (60 cm). Place the sealing gasket on the male part of clamp, insert it into the drilled hole, then clamp it into place using the provided screws. The saddle clamp has a 1/8” FNPT port; install either the supplied compression fitting or another style fitting suitable for plastic tubing. Two saddle clamps, one for air and one for water, are required for each nozzle.

NOTE

Not to be used with DI water.

For DI water use stainless steel tee.

Figure 6. Quick Release Fitting | Figure 7. Saddle Clamp |

Page 13