INSTALLATION IN EXISTING CONSTRUCTION

Use the following procedures for installation in existing construction. |

|

|

|

|

|

|

|

|

|

|

| ||||||||

Starting from farthest wall inlet location, install each inlet as described |

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

| |||||||||

below. Working back toward power unit, connect each inlet line and |

|

|

|

|

|

|

|

|

|

|

| ||||||||

branch line into main trunk line. See page 5. Complete low voltage wiring |

|

|

|

|

|

|

| BASEBOARD | |||||||||||

as main trunk line is continued back to power unit. Mount power unit and |

|

|

|

|

|

|

|

|

|

|

| ||||||||

complete wiring. See page 8. |

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TOE STRIP |

WALL INLET INSTALLATION |

|

|

|

|

|

|

|

|

|

|

| ||||||||

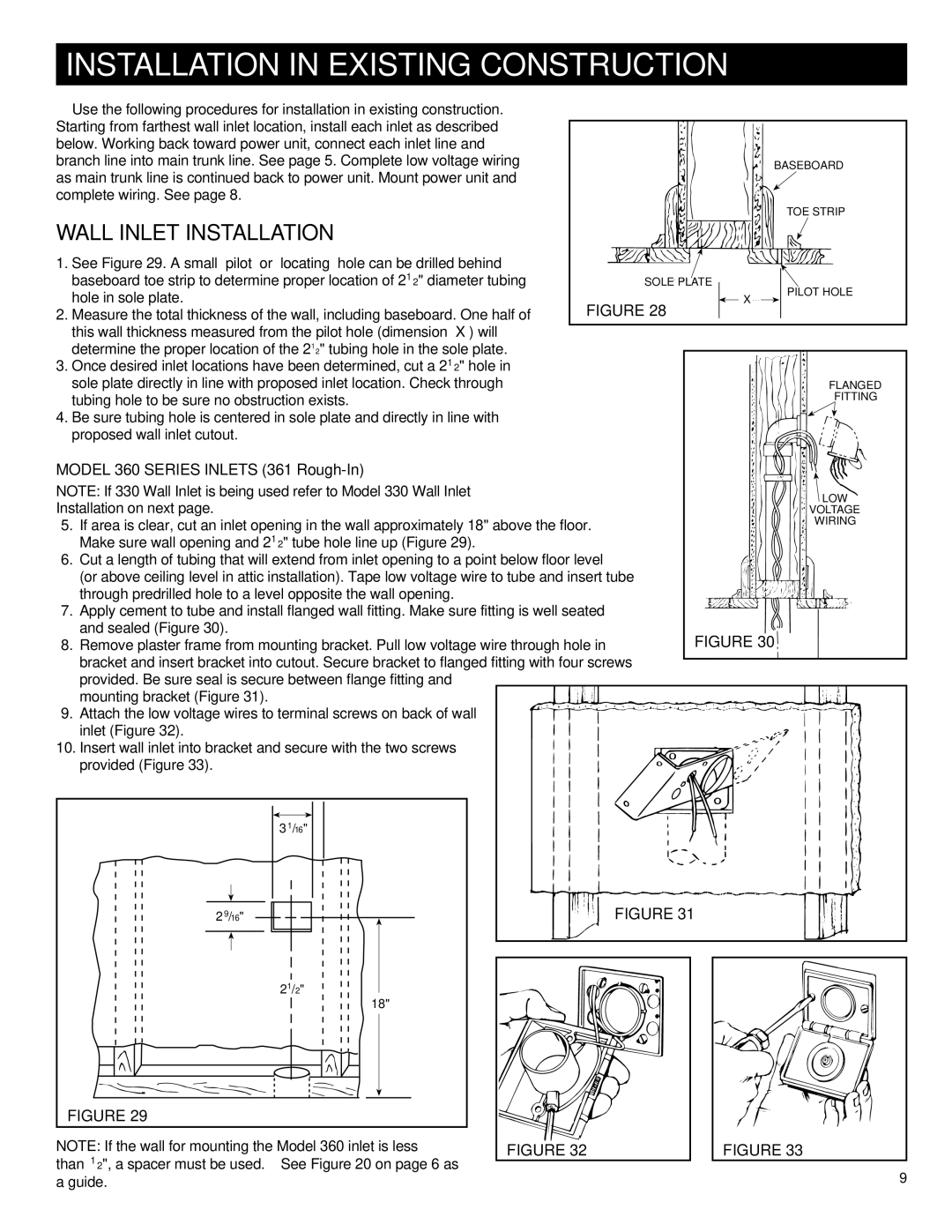

1. See Figure 29. A small ‘pilot’ or ‘locating’ hole can be drilled behind |

|

|

|

|

|

|

|

|

|

|

| ||||||||

baseboard toe strip to determine proper location of 21⁄2" diameter tubing |

| SOLE PLATE |

|

|

|

|

|

|

| PILOT HOLE | |||||||||

|

|

| |||||||||||||||||

hole in sole plate. |

|

|

|

|

|

| “X” |

|

|

| |||||||||

FIGURE 28 |

|

|

|

|

|

|

| ||||||||||||

2. Measure the total thickness of the wall, including baseboard. One half of |

|

|

|

|

|

|

|

| |||||||||||

|

| ||||||||||||||||||

this wall thickness measured from the pilot hole (dimension ‘X’) will |

|

|

|

|

|

|

|

|

|

|

| ||||||||

determine the proper location of the 21⁄2" tubing hole in the sole plate. |

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

| |||||||||

3. Once desired inlet locations have been determined, cut a 21⁄2" hole in |

|

|

|

|

|

|

|

|

|

|

| ||||||||

sole plate directly in line with proposed inlet location. Check through |

|

|

|

|

|

|

|

|

|

| FLANGED | ||||||||

tubing hole to be sure no obstruction exists. |

|

|

|

|

|

|

|

|

|

| FITTING | ||||||||

4. Be sure tubing hole is centered in sole plate and directly in line with |

|

|

|

|

|

|

|

|

|

|

| ||||||||

proposed wall inlet cutout. |

|

|

|

|

|

|

|

|

|

|

| ||||||||

MODEL 360 SERIES INLETS (361 |

|

|

|

|

|

|

|

|

|

|

| ||||||||

NOTE: If 330 Wall Inlet is being used refer to Model 330 Wall Inlet |

|

|

|

|

|

|

|

|

|

| LOW | ||||||||

Installation on next page. |

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

| VOLTAGE | |||||||||

5. If area is clear, cut an inlet opening in the wall approximately 18" above the floor. |

|

|

|

|

|

|

|

|

| WIRING | |||||||||

Make sure wall opening and 21⁄2" tube hole line up (Figure 29). |

|

|

|

|

|

|

|

|

|

|

| ||||||||

6. Cut a length of tubing that will extend from inlet opening to a point below floor level |

|

|

|

|

|

|

|

|

|

| |||||||||

(or above ceiling level in attic installation). Tape low voltage wire to tube and insert tube |

|

|

|

|

|

|

|

|

|

| |||||||||

through predrilled hole to a level opposite the wall opening. |

|

|

|

|

|

|

|

|

|

|

| ||||||||

7. Apply cement to tube and install flanged wall fitting. Make sure fitting is well seated |

|

|

|

|

|

|

|

|

|

| |||||||||

and sealed (Figure 30). |

|

| FIGURE 30 | ||||||||||||||||

8. Remove plaster frame from mounting bracket. Pull low voltage wire through hole in |

| ||||||||||||||||||

bracket and insert bracket into cutout. Secure bracket to flanged fitting with four screws |

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

| ||||||||||

provided. Be sure seal is secure between flange fitting and |

|

|

|

|

|

|

|

|

|

|

|

| |||||||

mounting bracket (Figure 31). |

|

|

|

|

|

|

|

|

|

|

| ||||||||

9. Attach the low voltage wires to terminal screws on back of wall |

|

|

|

|

|

|

|

|

|

|

| ||||||||

inlet (Figure 32). |

|

|

|

|

|

|

|

|

|

|

| ||||||||

10. Insert wall inlet into bracket and secure with the two screws |

|

|

|

|

|

|

|

|

|

|

| ||||||||

provided (Figure 33). |

|

|

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3 1/16" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 9/16" | FIGURE 31 |

21/2" |

|

|

18" |

|

|

FIGURE 29 |

|

|

NOTE: If the wall for mounting the Model 360 inlet is less | FIGURE 32 | FIGURE 33 |

than 1⁄2", a spacer must be used. See Figure 20 on page 6 as |

| 9 |

a guide. |

|