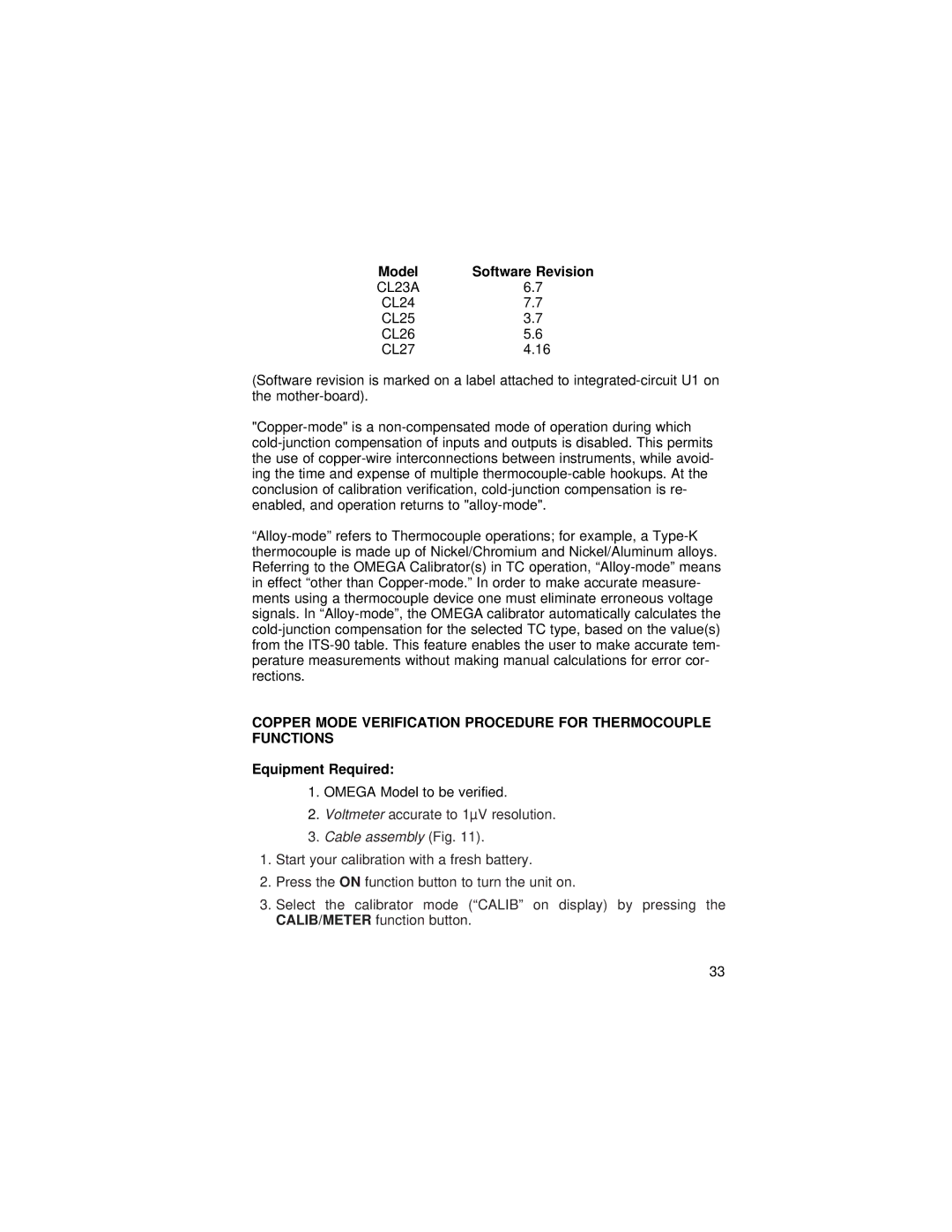

Model | Software Revision |

CL23A | 6.7 |

CL24 | 7.7 |

CL25 | 3.7 |

CL26 | 5.6 |

CL27 | 4.16 |

(Software revision is marked on a label attached to integrated-circuit U1 on the mother-board).

"Copper-mode" is a non-compensated mode of operation during which cold-junction compensation of inputs and outputs is disabled. This permits the use of copper-wire interconnections between instruments, while avoid- ing the time and expense of multiple thermocouple-cable hookups. At the conclusion of calibration verification, cold-junction compensation is re- enabled, and operation returns to "alloy-mode".

“Alloy-mode” refers to Thermocouple operations; for example, a Type-K thermocouple is made up of Nickel/Chromium and Nickel/Aluminum alloys. Referring to the OMEGA Calibrator(s) in TC operation, “Alloy-mode” means in effect “other than Copper-mode.” In order to make accurate measure- ments using a thermocouple device one must eliminate erroneous voltage signals. In “Alloy-mode”, the OMEGA calibrator automatically calculates the cold-junction compensation for the selected TC type, based on the value(s) from the ITS-90 table. This feature enables the user to make accurate tem- perature measurements without making manual calculations for error cor- rections.

COPPER MODE VERIFICATION PROCEDURE FOR THERMOCOUPLE FUNCTIONS

Equipment Required:

1.OMEGA Model to be verified.

2.Voltmeter accurate to 1µV resolution.

3.Cable assembly (Fig. 11).

1.Start your calibration with a fresh battery.

2.Press the ON function button to turn the unit on.

3.Select the calibrator mode (“CALIB” on display) by pressing the CALIB/METER function button.