M3594m0603mCDE681Series.qxd 7/17/03 2:14 PM Page 5 | m |

-

CDE681 Part 2 - lnsta~~ation

OPTIONAL

NYo;t

;pC;;ESSION$

REDUCER

(ASREQUIRED)

PROLESS

FLOW

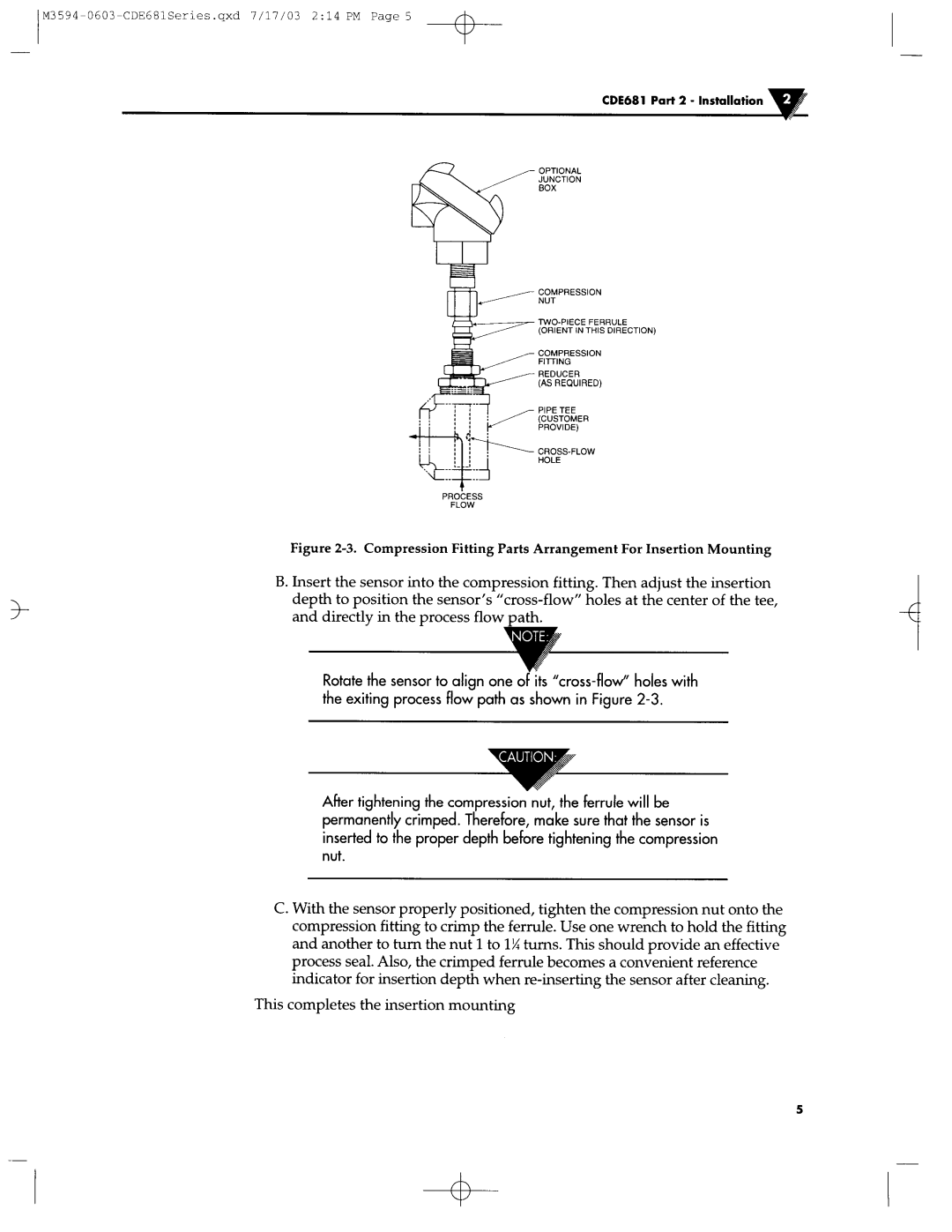

Figure 2-3. Compression Fitting Parts Arrangement For Insertion Mounting

B.Insert the sensor into the compression fitting. Then adjust the insertion

, | de&h to oosition the sensor ’s | ||

f | and direitly in the process | flow path. |

|

| Rotate the sensor to align one or its | ||

| the exiting process flow path as shown in Figure | ||

After tightening the compression nut, the ferrule will be permanently crimped. Therefore, make sure that the sensor is

inserted to the proper depth before tightening the compression nut.

C. With the sensor properly positioned, tighten the compression nut onto the compression fitting to crimp the ferrule. Use one wrench to hold the fitting and another to turn the nut 1 to 1% turns. This should provide an effective process seal. Also, the crimped ferrule becomes a convenient reference indicator for insertion depth when