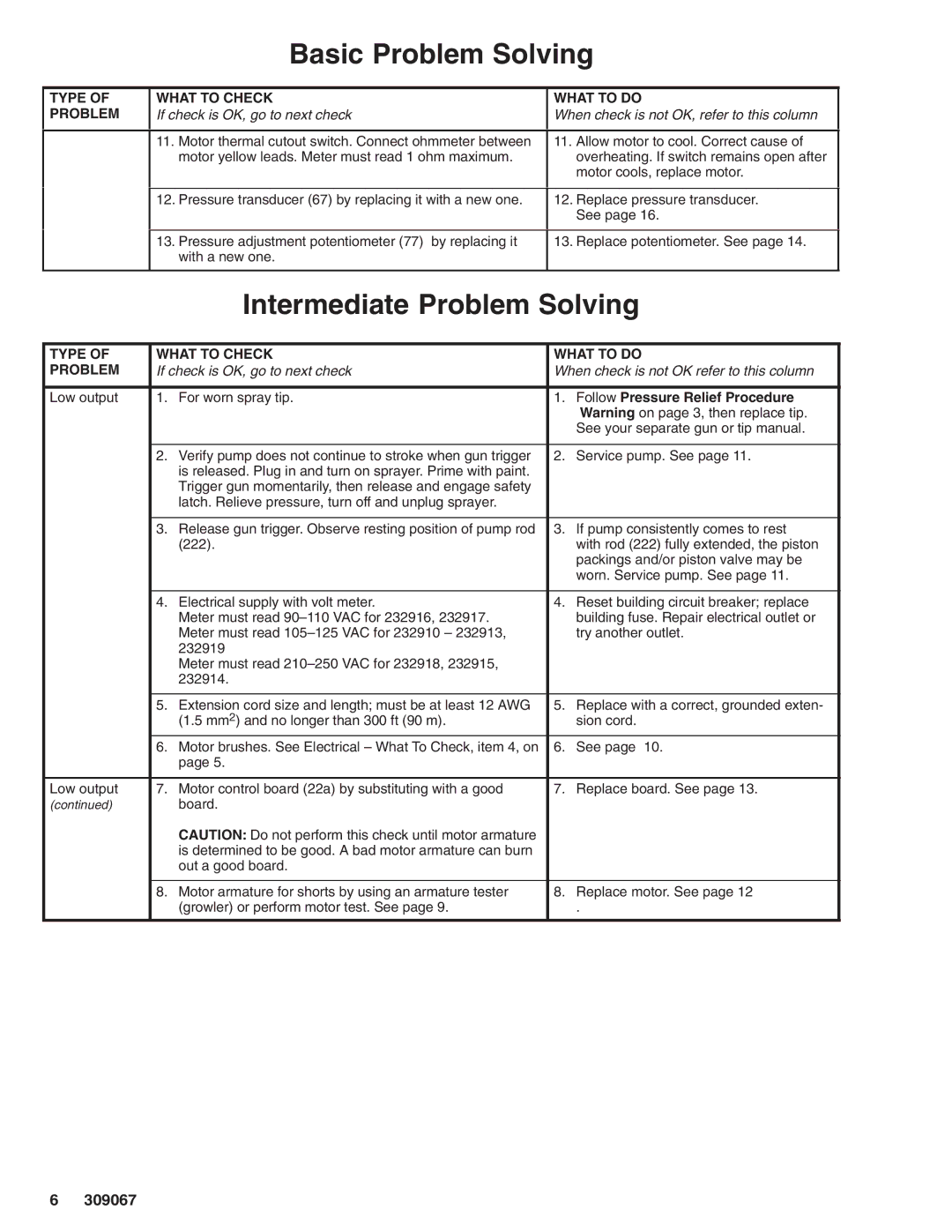

Basic Problem Solving

TYPE OF | WHAT TO CHECK | WHAT TO DO | ||

PROBLEM | If check is OK, go to next check | When check is not OK, refer to this column | ||

|

|

|

|

|

| 11. | Motor thermal cutout switch. Connect ohmmeter between | 11. | Allow motor to cool. Correct cause of |

|

| motor yellow leads. Meter must read 1 ohm maximum. |

| overheating. If switch remains open after |

|

|

|

| motor cools, replace motor. |

|

|

| ||

| 12. Pressure transducer (67) by replacing it with a new one. | 12. Replace pressure transducer. | ||

|

|

|

| See page 16. |

|

|

| ||

| 13. Pressure adjustment potentiometer (77) by replacing it | 13. Replace potentiometer. See page 14. | ||

|

| with a new one. |

|

|

|

|

|

| |

|

| Intermediate Problem Solving | ||

|

|

| ||

TYPE OF | WHAT TO CHECK | WHAT TO DO | ||

PROBLEM | If check is OK, go to next check | When check is not OK refer to this column | ||

|

|

|

|

|

Low output | 1. | For worn spray tip. | 1. | Follow Pressure Relief Procedure |

|

|

|

| Warning on page 3, then replace tip. |

|

|

|

| See your separate gun or tip manual. |

|

|

|

|

|

| 2. | Verify pump does not continue to stroke when gun trigger | 2. | Service pump. See page 11. |

|

| is released. Plug in and turn on sprayer. Prime with paint. |

|

|

|

| Trigger gun momentarily, then release and engage safety |

|

|

|

| latch. Relieve pressure, turn off and unplug sprayer. |

|

|

|

|

|

|

|

| 3. | Release gun trigger. Observe resting position of pump rod | 3. | If pump consistently comes to rest |

|

| (222). |

| with rod (222) fully extended, the piston |

|

|

|

| packings and/or piston valve may be |

|

|

|

| worn. Service pump. See page 11. |

|

|

|

|

|

| 4. | Electrical supply with volt meter. | 4. | Reset building circuit breaker; replace |

|

| Meter must read |

| building fuse. Repair electrical outlet or |

|

| Meter must read |

| try another outlet. |

|

| 232919 |

|

|

|

| Meter must read |

|

|

|

| 232914. |

|

|

|

|

|

|

|

| 5. | Extension cord size and length; must be at least 12 AWG | 5. | Replace with a correct, grounded exten- |

|

| (1.5 mm2) and no longer than 300 ft (90 m). |

| sion cord. |

| 6. | Motor brushes. See Electrical – What To Check, item 4, on | 6. | See page 10. |

|

| page 5. |

|

|

|

|

|

|

|

Low output | 7. | Motor control board (22a) by substituting with a good | 7. | Replace board. See page 13. |

(continued) |

| board. |

|

|

|

| CAUTION: Do not perform this check until motor armature |

|

|

|

| is determined to be good. A bad motor armature can burn |

|

|

|

| out a good board. |

|

|

|

|

|

|

|

| 8. | Motor armature for shorts by using an armature tester | 8. | Replace motor. See page 12 |

|

| (growler) or perform motor test. See page 9. |

| . |

|

|

|

|

|

6309067