OEM650X, OEM650, OEM350, OEM350X specifications

Parker Products provides an exceptional lineup of industrial-grade portable adhesive applicators, including the OEM350X, OEM350, OEM650, and OEM650X. These models are designed to meet the demands of various manufacturing processes, delivering reliable and precise adhesive application for diverse industries such as automotive, woodworking, and packaging.The OEM350 series, including both OEM350 and OEM350X, is characterized by its lightweight yet durable construction, allowing for ease of handling and transport. This series is particularly known for its versatility in handling various adhesive types, including polyurethane, hot melt, and cyanoacrylate adhesives. The OEM350 features a robust performance with a maximum output of 350 lbs per hour, ensuring efficient production rates while maintaining high-quality bonding. The OEM350X variant enhances these features with advanced temperature control technology, enabling users to maintain optimal adhesive viscosity for different applications.

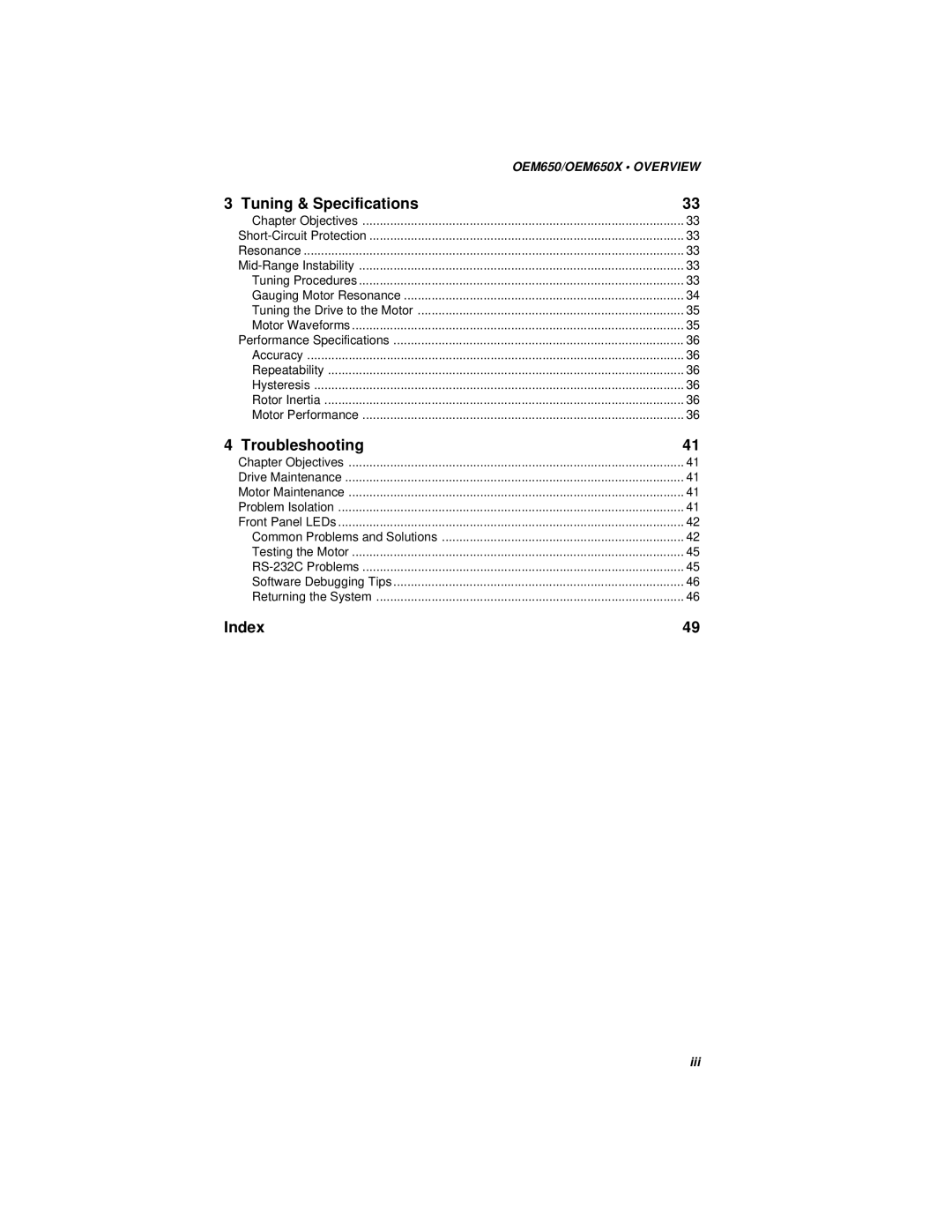

On the other hand, the OEM650 and OEM650X models are designed for heavier-duty applications. The OEM650 can deliver up to 650 lbs of adhesive per hour, making it suitable for high-volume manufacturing processes. Its larger tank capacity and efficient heating mechanism allow for extended operational periods between refills, which significantly boosts productivity. The OEM650X takes performance a notch higher with integrated smart technology, which provides real-time monitoring of adhesive quality and system health, helping to reduce downtime and maintain efficiency in production.

All models in this range are equipped with user-friendly interfaces for easy operation. The control panels allow operators to set precise temperature and pressure settings, which can be adjusted to fit particular production needs. Additionally, the equipment is built with safety features such as automatic shut-offs and alarm systems, ensuring safe operation in busy manufacturing environments.

Parker Products’ OEM series stands out not only for its performance but also for its commitment to innovation. With advancements like modular design for easy maintenance and scalability, these applicators are designed to grow with your business. The robust performance, versatile application, and advanced technologies of the OEM350X, OEM350, OEM650, and OEM650X make them invaluable tools in the modern manufacturing landscape, driving efficiency and quality in adhesive applications.