Monarch Printers

9412 9413 9414

Canadian D.O.C. Warning

Table of Contents

B L E O F C O N T E N T S

T T ING Started

S Igning a Format

F Ining Fields

I N T I N G

Status Polling

Iv Table of Contents

A G N O S TI C S

Page

Vi Table of Contents

T T I N G S T a R T E D

O u t T h i s M a n u a l

Feature 9412 9413 9414

F o r e Y o u B e g i n

E a t i n g a n M P C L I I F o r m a t P a c k e t

Type the following constant text field

Type the following bar code field

Type the following text field

Type the following bar code data

I l y S t a r t u p P r o c e d u r e s

Sample Batch Packet

6Getting Started

S I G N I N G a F O R M a T

A r t i n g w i t h a D e s i g n

T e r m i n i n g F o r m a t C o n t e n t s

T e r m i n i n g t h e P r i n t a r e a

A w i n g R o u g h S k e t c h e s

I n g S u p p l y L a y o u t G r i d s

Page

All of the above field types are discussed Chapter

N s i d e r i n g F i e l d Ty p e s

N s i d e r i n g F o n t s

I n g t h e F o r m a t W o r k s h e e t

L l i n g i n t h e F o r m a t W o r k s h e e t

8Designing a Format

N F I G U R I N G T H E P R I N T E R

T t i n g C o m m u n i c a t i o n P a r a m e t e r s

I n g P a r a l l e l C o m m u n i c a t i o n s

I n g M P C L I I C o n v e n t i o n s

C L I I P u n c t u a t i o n

A n d a r d S y n t a x G u i d e l i n e s

‘comment‘

Page

I n g O n l i n e C o n f i g u r a t i o n P a c k e t s

N f i g u r a t i o n P a c k e t H e a d e r

6Configuring the Printer

Header,ID#,action,device p

Example

N f i g u r a t i o n S y n t a x G u i d e l i n e s

Syntax I,A,powupmode,language,sepon,slashzero, symbolset p

F i n i n g t h e S y s t e m S e t u p P a c k e t

10Configuring the Printer

F i n i n g t h e S u p p l y S e t u p P a c k e t

Supplytype,ribbonon,feedmode

Supplyposn,cutposn p

F i n i n g t h e P r i n t C o n t r o l P a c k e t

C1. C Print Control Packet

1,1,2 p

ANSIcd,string1,string2 p

Def. ch

14Configuring the Printer

S e t t i n g C o n t r o l C h a r a c t e r s

Syntax I,F,baud,wordlength,stopbits,parity, flowcontrol p

16Configuring the Printer

I,R,1530 p

O u t M e m o r y B u f f e r s

E c k i n g C u r r e n t B u f f e r S i z e s

22K x Length

F f e r W o r k s h e e t

F f e r a l l o c a t i o n C o n s i d e r a t i o n s

R,N,20 p M,T,N,60 p

N d i n g I m m e d i a t e C o m m a n d s

I n g I m m e d i a t e C o m m a n d s

A b l i n g I m m e d i a t e C o m m a n d s

Command Parameter

Clears Format #1 from volatile RAM 24Configuring the Printer

E a r i n g P a c k e t s f r o m M e m o r y

I n g t h e F o n t P a c k e t

Font#,action,device p

Spacing

Type

Baseline

Cell Width

F I N I N G F I E L D S

F i n i n g t h e F o r m a t H e a d e r

Format Header begins a format file

2Defining Fields

Format#,action,device,measure,length

F i n i n g T e x t F i e l d s

A,R,E,300,200,TEXTILES p

4Defining Fields

9412/9414 ranges

Line field Line field not Blocked out by

6Defining Fields

T12. alignment Options

F i n i n g B a r code F i e l d s

Each bar code field requires a separate definition

Left/Center/Right-Justified Fields Balanced Fields

8Defining Fields

B7. font Bar code. Options

10Defining Fields

MOD43

Bar code Density Narrow Narrow to Data Appearance Char Set

F i n i n g N o n P r i n t a b l e T e x t F i e l d s

20 p

Field Data Field Type

Field#,# of char p

F i n i n g C o n s t a n t T e x t F i e l d s

9412/9414 ranges

Dots

16Defining Fields

F i n i n g L i n e F i e l d s

N e Ty p e s

Segments

Vectors

L5. angle/ If Using Segments end row

18Defining Fields

Example L,S,110,30,110,150,10, p

F i n i n g B o x F i e l d s

20Defining Fields

Row,column,end row,end col,thickness

Pattern p

Example Q,240,30,270,150,3, p

22Defining Fields

M b i n i n g F i e l d O p t i o n s

F I N I N G F I E L D O P T I O N S

P l y i n g F i e l d O p t i o n s

S t r i c t i o n s

2Defining Field Options

3,1,3,1,1 p

Option#,parameter...parameter p

%$ p

T i o n 1 F i x e d D a t a

Fixed char p

T i o n 4 C o p y D a t a

4Defining Field Options

Src fld,src start,# to copy,dest

Start,copy code p

203 Non-printable 339 Text

R g i n g F i e l d s

B F i e l d s

T i o n 3 0 P a d d i n g D a t a

M p l e U s e f o r P a d d i n g

Pads data with an X on the left side of the field

30,L/R,character p

T i o n 3 1 C a l c u l a t e C h e c k D i g i t

31,gen/ver,check digit # p

42,1 p

T i o n 4 2 P r i c e F i e l d

42,appearance code p

50,4,8,4,4,8 p

T i o n 5 0 B a r code D e n s i t y

50,narrow,wide,gap,narspace,widespace p

51,2,S p

51,security,stand/default p

10Defining Field Options

52,row/column,dimension p

T i o n 5 2 P D F 4 1 7 W i d t h / L e n g t h

60,I/D,amount,l pos,r pos p

60,I,5,1,6 p

T i o n 6 1 R e i m a g e F i e l d

61 p

Fldlength,D/P,weights p

I n g C h e c k D i g i t s

14Defining Field Options

Selector,action,device,modulus

M o f P r o d u c t s C a l c u l a t i o n

1,2,3,4

M o f D i g i t s C a l c u l a t i o n

16Defining Field Options

10 4 =

18Defining Field Options

I N T I N G

Page

N,1 p

F i n i n g t h e B a t c h H e a d e r

Format#,N/U,quantity p

F i n i n g t h e B a t c h C o n t r o l F i e l d

1,4,2 p

F i n i n g B a t c h D a t a F i e l d s

Sample Batch Data with Special Characters

R g e d o r S u b F i e l d s

C r e m e n t i n g F i e l d s

W n l o a d i n g M e t h o d s

Q u e n t i a l M e t h o d

T c h M e t h o d

T c h Q u a n t i t y Z e r o M e t h o d

D i f y i n g F o r m a t s

T i o n a l E n t r y M e t h o d

Mode COM1 9600,N,8,1,P

10Printing

A T U S P O L L I N G

Indicates the printer is offline 2Status Polling

Q u i r y R e q u e s t E N Q

Q u i r y R e s p o n s e

Page

Q R e f e r e n c e Ta b l e B y t e #

Q R e f e r e n c e Ta b l e B y t e # 2 c o n t i n u e d

Char Const Low Format Waiting Ribbon Stock Online

Q R e f e r e n c e Ta b l e B y t e # 3 c o n t i n u e d

B R e q u e s t

Syntax J,#

B R e s p o n s e

Status1,Status2,FMT-1,BCH-2

Status2

Packet Type

Error Number

Field Number

Parameter

FMT-1/BCH-2

25,FMT-3,Bch-2

Following syntax is the response for a Job 4 request

Printed,total,FMT-1,BCH-2

Number Meaning

14Status Polling

A G N O S T I C S

I n t i n g a Te s t L a b e l

I n g D a t a D u m p

Y o u R e c e i v e a n Error M e s s a g e

Tr o u b l e s h o o t i n g I n f o r m a t i o n

L l i n g Te c h n i c a l S u p p o r t

S e t t i n g P r i n t e r s

Page

Error S

T a Error s

Error Description Code

Page

Page

Page

Page

Page

Page

Page

M m u n i c a t i o n F a i l u r e s

Page

T a F o r m a t t i n g F a i l u r e s

C h i n e Fault s

Page

Page

Page

M P L E SA

M p l e U P C a F o r m a t P a c k e t

2Samples

M p l e M a x i code P a c k e t s

D e 0 O b s o l e t e S a m p l e

4Samples

D e 2 S a m p l e

Samples A-5

D e 3 S a m p l e

6Samples

M p l e C o m p l i a n c e P a c k e t

Samples A-7

8Samples

Samples A-9

M p l e F o r m a t P a c k e t

10Samples

Sample Zero Batch Packet

Samples A-11

12Samples

Your printer comes with these fonts loaded in ROM

N T SB

A n d a r d F o n t s

These samples were printed using the Internal Symbol set

Standard Font

Bold Font

2Fonts

Fonts B-3

These samples were printed using Code

CG Triumvirate Bold Font

N o s p a c e d F o n t M a g n i f i c a t i o n

Width Mag Standard Reduced Bold

Fonts B-5

Height Magnification

O p o r t i o n a l F o n t M a g n i f i c a t i o n

Tr i u m v i r a t e B o l d 9 p t

Tr i u m v i r a t e 6 p t

Fonts B-7

Font Number

L e c t i n g t h e I n t e r n a l S y m b o l S e t

P p o r t e d S y m b o l S e t s a n d code P a g e s

L e c t i n g a S y m b o l S e t o r code P a g e

I n g code 1 2 8 F u n c t i o n codes

T e r i n g E x t e n d e d C h a r a c t e r s

L e c t i n g t h e a N S I S y m b o l S e t

L e c t i n g t h e 4 3 7 o r 8 5 0 code P a g e

T e r n a l S y m b o l S e t

S I S y m b o l S e t

L d C h a r a c t e r S e t

R a C h a r a c t e r S e t

Code P a g e 4 3

Code P a g e 8 5

Symbol Sets/Code Pages C-9

Char Hex Decimal

10Symbol Sets/Code Pages

Symbol Sets/Code Pages C-11

12Symbol Sets/Code Pages

R M a T D E S I G N T O O L S D

L i n e C o n f i g u r a t i o n W o r k s h e e t

2Format Design Tools

T c h W o r k s h e e t

Format Design Tools D-3

E c k D i g i t W o r k s h e e t

4Format Design Tools

O S S a R Y

Non-volatile RAM

Option

6,1,3,1 p

Packet

D E

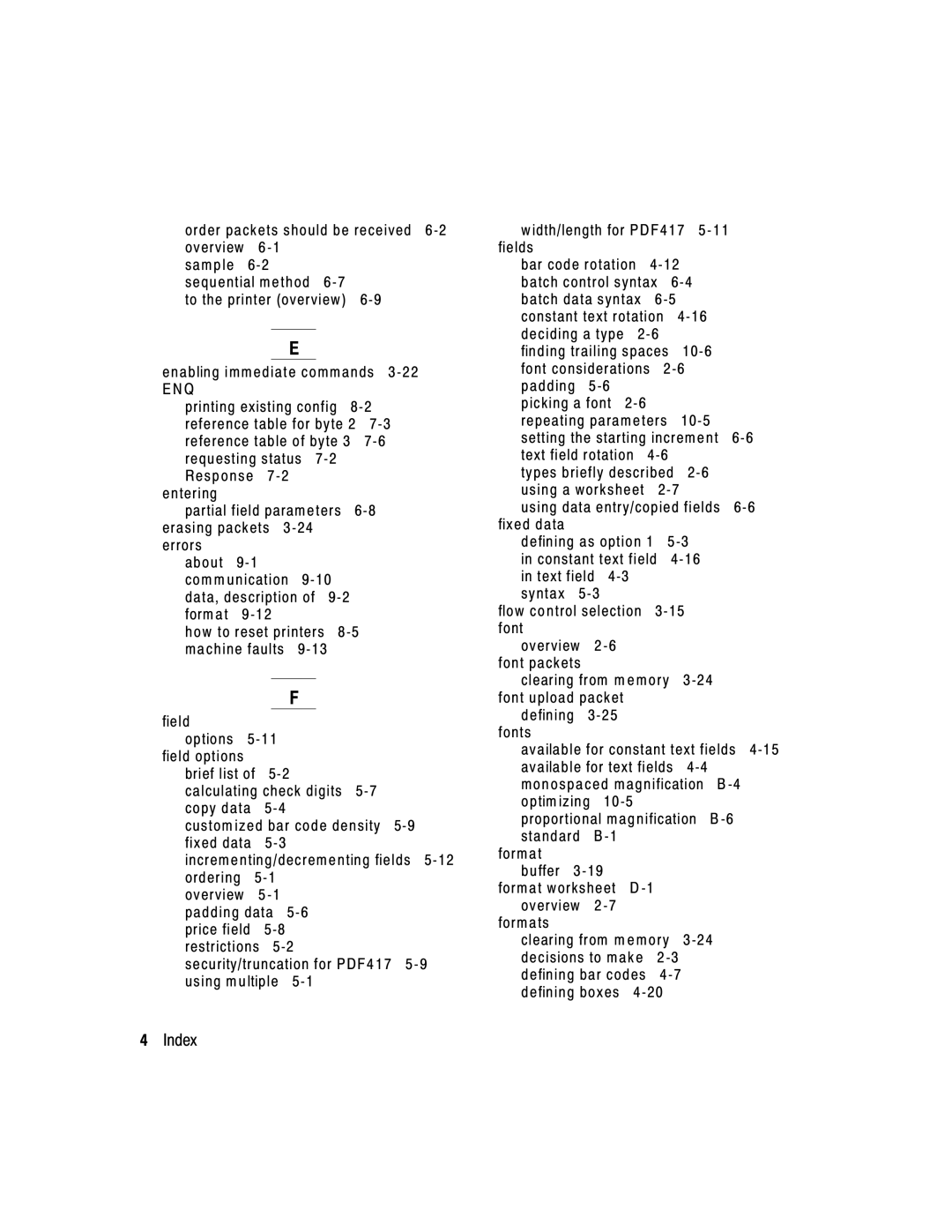

Index

Padding

Syntax Copying data, using option Creating S b a tch files

Data, description

IMD

A text field Lines Defining

Configuration Guidelines Padding data Syntax

Problem s Check digit m iscalculated

Text field Zero batch packet Scalable font Buffer

D ifying character spacing