WATER PIPING AND CONTROLS

6.Install this boiler so that the gas ignition system components are protected from water (dripping, spraying, etc.) during appliance operation and service (circulator replacement, condensate trap, control replacements, etc.).

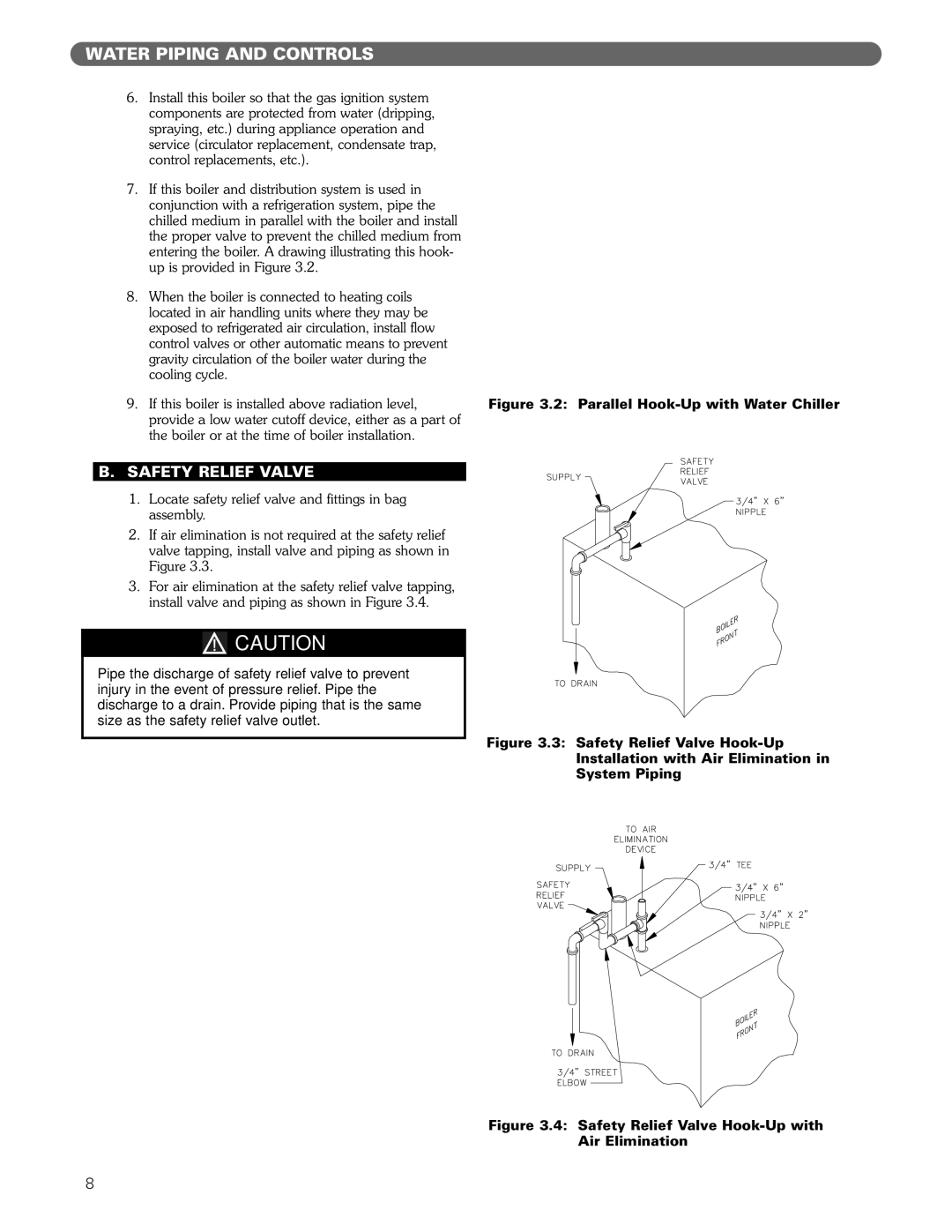

7.If this boiler and distribution system is used in conjunction with a refrigeration system, pipe the chilled medium in parallel with the boiler and install the proper valve to prevent the chilled medium from entering the boiler. A drawing illustrating this hook- up is provided in Figure 3.2.

8.When the boiler is connected to heating coils located in air handling units where they may be exposed to refrigerated air circulation, install flow control valves or other automatic means to prevent gravity circulation of the boiler water during the cooling cycle.

9. If this boiler is installed above radiation level, | Figure 3.2: Parallel |

provide a low water cutoff device, either as a part of |

|

the boiler or at the time of boiler installation. |

|

B. SAFETY RELIEF VALVE

1. Locate safety relief valve and fittings in bag assembly.

2. If air elimination is not required at the safety relief valve tapping, install valve and piping as shown in Figure 3.3.

3.For air elimination at the safety relief valve tapping, install valve and piping as shown in Figure 3.4.

![]() CAUTION

CAUTION

Pipe the discharge of safety relief valve to prevent injury in the event of pressure relief. Pipe the discharge to a drain. Provide piping that is the same size as the safety relief valve outlet.

Figure 3.3: Safety Relief Valve Hook-Up

Installation with Air Elimination in

System Piping

Figure 3.4: Safety Relief Valve Hook-Up with

Air Elimination

8