E.CHECKING BURNER INPUT

1.Refer to rating label mounted on the jacket top panel to obtain the rated BTU per hour input. In no case shall the input to the boiler exceed the value shown on the rating label.

2.Check input by use of the following formulas

(PB Heat, LLC suggests reading meter for 2 Cu. Ft.):

U.S. Customary Units

Input (BTU/Hr.)= 3600 x F x H

T

Where:

3600 – Seconds per hour

F – Cubic Feet of Gas Registered on Meter H – Heat Value of Gas in BTU/Cubic Feet T – Time in Seconds the Meter is Read

SI Metric Units

Input (kW)= 3600 x F x H

T x 3.6

Where:

3600 – Seconds per hour

3.6– Megajoule (MJ) per kilowatt hour (kwhr) F – Cubic Meters of Gas Registered on Meter H – Heating Value of Gas in MJ/Cubic Meter T – Time in Seconds the Meter is Read

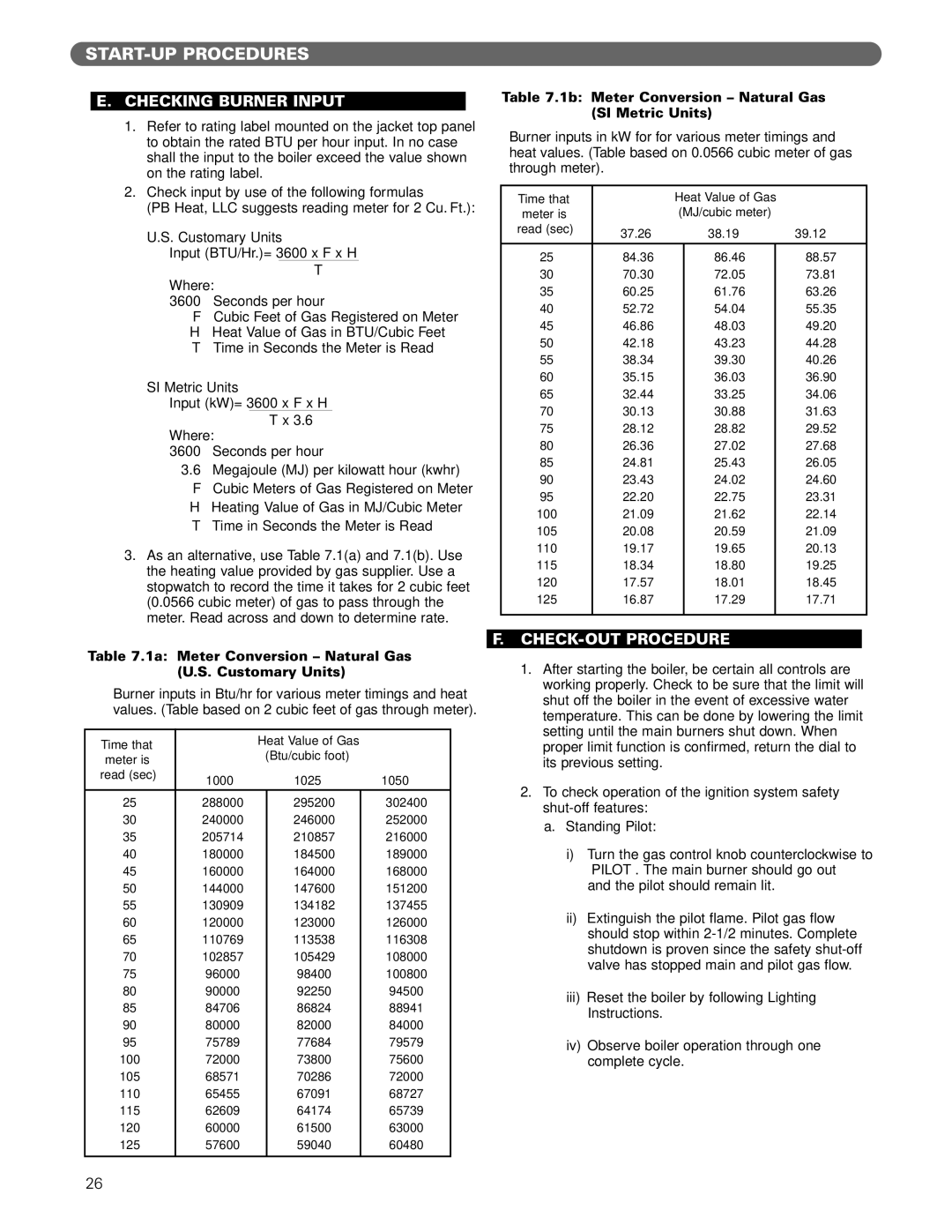

3.As an alternative, use Table 7.1(a) and 7.1(b). Use the heating value provided by gas supplier. Use a stopwatch to record the time it takes for 2 cubic feet (0.0566 cubic meter) of gas to pass through the meter. Read across and down to determine rate.

Table 7.1a: Meter Conversion – Natural Gas (U.S. Customary Units)

Burner inputs in Btu/hr for various meter timings and heat values. (Table based on 2 cubic feet of gas through meter).

Time that |

| Heat Value of Gas |

| ||

| (Btu/cubic foot) |

| |||

meter is |

|

| |||

|

|

|

|

| |

read (sec) | 1000 | 1025 |

| 1050 | |

|

| ||||

25 | 288000 |

| 295200 |

| 302400 |

30 | 240000 |

| 246000 |

| 252000 |

35 | 205714 |

| 210857 |

| 216000 |

40 | 180000 |

| 184500 |

| 189000 |

45 | 160000 |

| 164000 |

| 168000 |

50 | 144000 |

| 147600 |

| 151200 |

55 | 130909 |

| 134182 |

| 137455 |

60 | 120000 |

| 123000 |

| 126000 |

65 | 110769 |

| 113538 |

| 116308 |

70 | 102857 |

| 105429 |

| 108000 |

75 | 96000 |

| 98400 |

| 100800 |

80 | 90000 |

| 92250 |

| 94500 |

85 | 84706 |

| 86824 |

| 88941 |

90 | 80000 |

| 82000 |

| 84000 |

95 | 75789 |

| 77684 |

| 79579 |

100 | 72000 |

| 73800 |

| 75600 |

105 | 68571 |

| 70286 |

| 72000 |

110 | 65455 |

| 67091 |

| 68727 |

115 | 62609 |

| 64174 |

| 65739 |

120 | 60000 |

| 61500 |

| 63000 |

125 | 57600 |

| 59040 |

| 60480 |

|

|

|

|

|

|

Table 7.1b: Meter Conversion – Natural Gas (SI Metric Units)

Burner inputs in kW for for various meter timings and heat values. (Table based on 0.0566 cubic meter of gas through meter).

Time that |

| Heat Value of Gas |

| ||

meter is |

| (MJ/cubic meter) |

| ||

read (sec) | 37.26 | 38.19 |

| 39.12 | |

|

| ||||

|

|

|

|

| |

25 | 84.36 |

| 86.46 |

| 88.57 |

30 | 70.30 |

| 72.05 |

| 73.81 |

35 | 60.25 |

| 61.76 |

| 63.26 |

40 | 52.72 |

| 54.04 |

| 55.35 |

45 | 46.86 |

| 48.03 |

| 49.20 |

50 | 42.18 |

| 43.23 |

| 44.28 |

55 | 38.34 |

| 39.30 |

| 40.26 |

60 | 35.15 |

| 36.03 |

| 36.90 |

65 | 32.44 |

| 33.25 |

| 34.06 |

70 | 30.13 |

| 30.88 |

| 31.63 |

75 | 28.12 |

| 28.82 |

| 29.52 |

80 | 26.36 |

| 27.02 |

| 27.68 |

85 | 24.81 |

| 25.43 |

| 26.05 |

90 | 23.43 |

| 24.02 |

| 24.60 |

95 | 22.20 |

| 22.75 |

| 23.31 |

100 | 21.09 |

| 21.62 |

| 22.14 |

105 | 20.08 |

| 20.59 |

| 21.09 |

110 | 19.17 |

| 19.65 |

| 20.13 |

115 | 18.34 |

| 18.80 |

| 19.25 |

120 | 17.57 |

| 18.01 |

| 18.45 |

125 | 16.87 |

| 17.29 |

| 17.71 |

|

|

|

|

|

|

F.CHECK-OUT PROCEDURE

1.After starting the boiler, be certain all controls are working properly. Check to be sure that the limit will shut off the boiler in the event of excessive water temperature. This can be done by lowering the limit setting until the main burners shut down. When proper limit function is confirmed, return the dial to its previous setting.

2.To check operation of the ignition system safety

a. Standing Pilot:

i)Turn the gas control knob counterclockwise to “PILOT”. The main burner should go out and the pilot should remain lit.

ii)Extinguish the pilot flame. Pilot gas flow should stop within

iii)Reset the boiler by following Lighting Instructions.

iv)Observe boiler operation through one complete cycle.

26