1.5INITIAL ADJUSTMENTS

After your fryer has been installed as described in section 1.4, it needs to be adjusted to ensure that it will perform as designed. These adjustments must be performed by a qualified person. To perform these adjustment the following tools will be needed:

• Manometer (low pressure gauge) | • Digital Thermometer (Temperature probe) |

• DC Millivolt Meter |

|

1.5.1 Visual Checks |

|

Before you begin filling and adjusting the fryer, perform the following visual checks:

a.After the fryer is in its permanent location check the level- ness. Any additional leveling that is necessary can be performed as described in section 1.3.

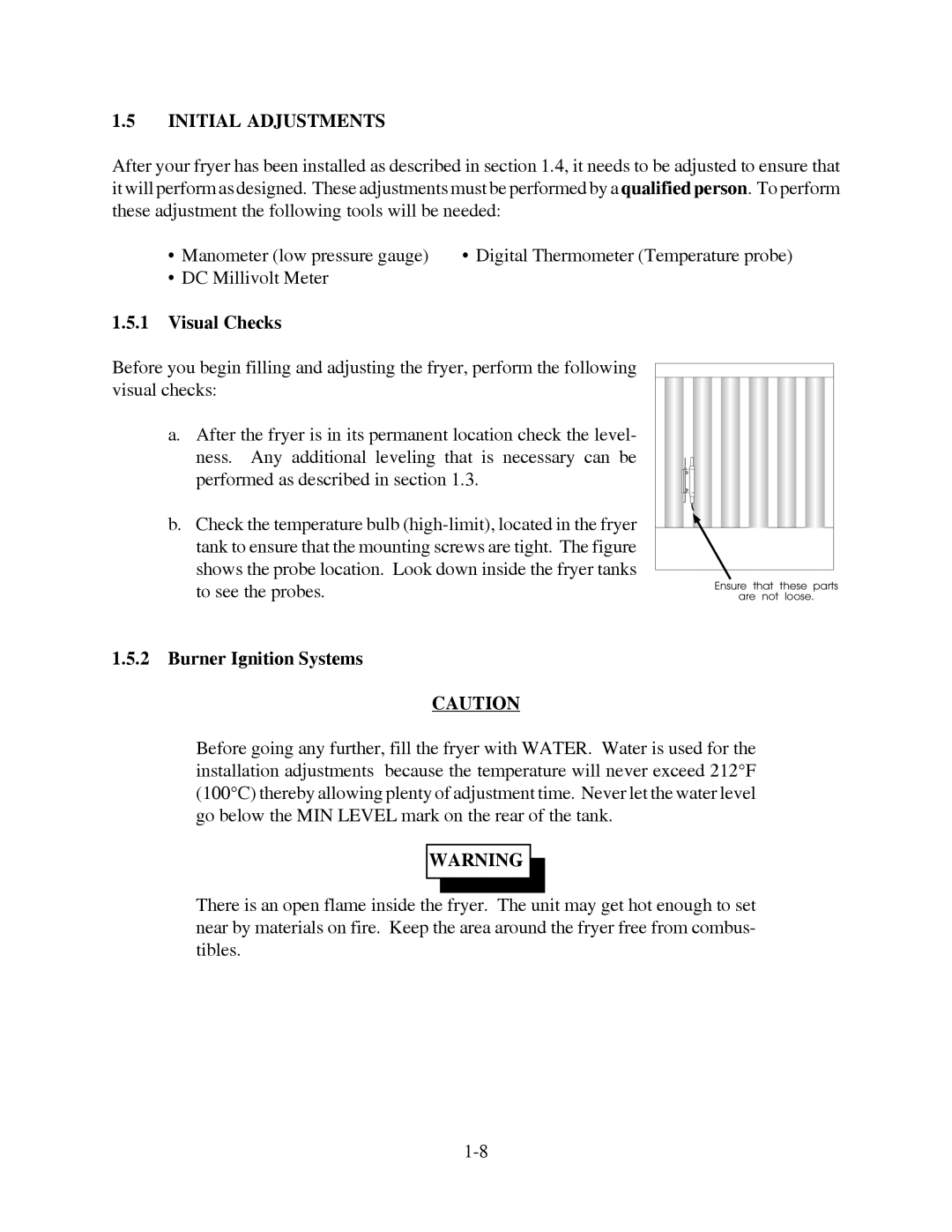

b.Check the temperature bulb

Ensure that these parts

are not loose.

1.5.2Burner Ignition Systems

CAUTION

Before going any further, fill the fryer with WATER. Water is used for the installation adjustments because the temperature will never exceed 212°F (100°C) thereby allowing plenty of adjustment time. Never let the water level go below the MIN LEVEL mark on the rear of the tank.

WARNING ![]()

There is an open flame inside the fryer. The unit may get hot enough to set near by materials on fire. Keep the area around the fryer free from combus- tibles.