HALF-PINS VS. HALF-TAILS

Traditionally, dovetails have

G1

G2

TEAROUT REDUCTION

Tearout is unwanted splintering of the wood fibers that occurs when a router bit enters, exits, or skims the edge of wood and is common to all dovetail jigs. Tearout cannot be eliminated, but it can be reduced by the insertion of additional scrap wood against the workpiece.

ALIGNING THE TEMPLATES

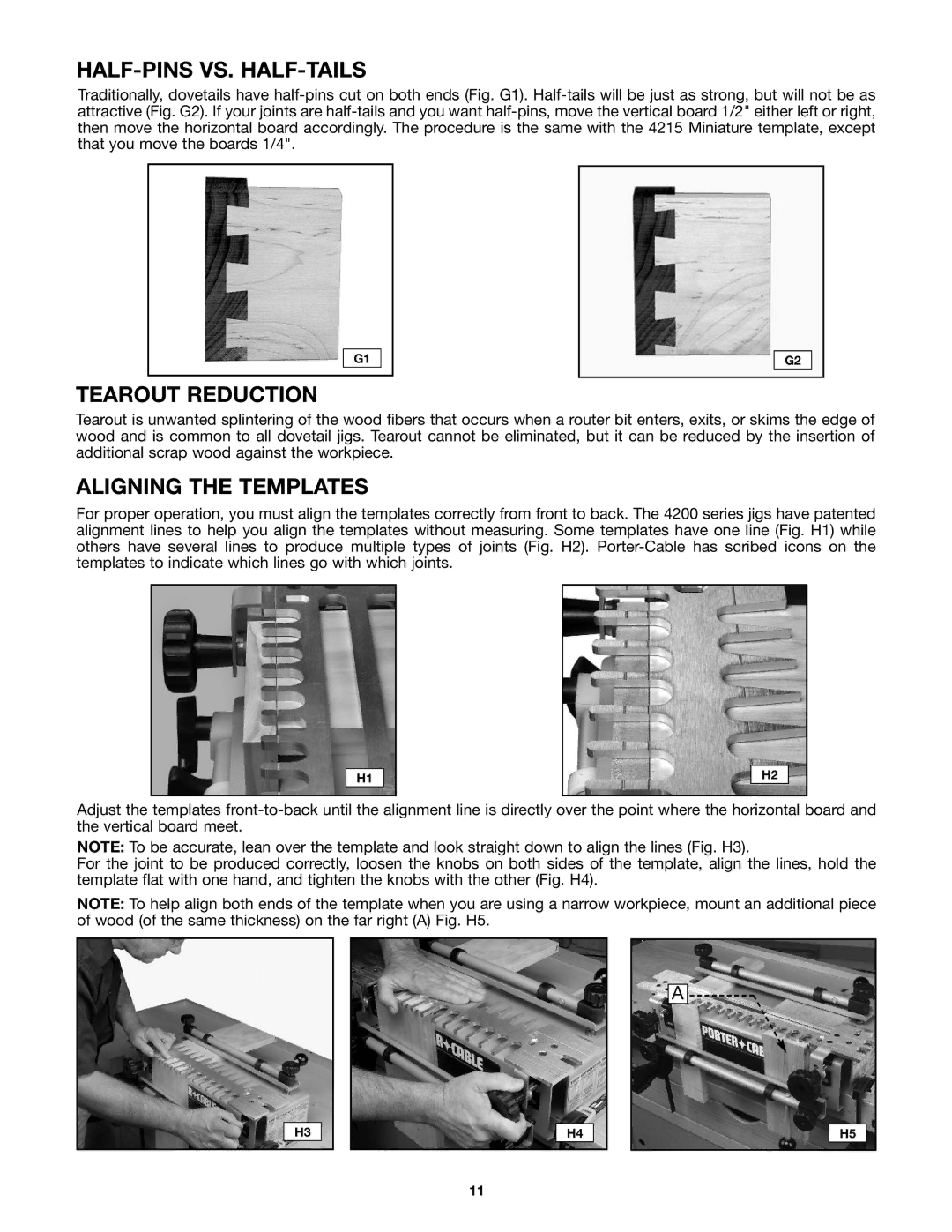

For proper operation, you must align the templates correctly from front to back. The 4200 series jigs have patented alignment lines to help you align the templates without measuring. Some templates have one line (Fig. H1) while others have several lines to produce multiple types of joints (Fig. H2).

H1

H2

Adjust the templates

NOTE: To be accurate, lean over the template and look straight down to align the lines (Fig. H3).

For the joint to be produced correctly, loosen the knobs on both sides of the template, align the lines, hold the template flat with one hand, and tighten the knobs with the other (Fig. H4).

NOTE: To help align both ends of the template when you are using a narrow workpiece, mount an additional piece of wood (of the same thickness) on the far right (A) Fig. H5.

A ![]()

![]()

![]()

H3

H4

H5

11