OPERATION

Mount your workpiece in the jig properly. If the workpiece is not secure, it can be damaged when it moves.

The jigs utilize two mounting positions for workpieces - horizontal and vertical. Some joints require both, while others require the use of a scrap board in the horizontal position (upper clamp) and the workpiece in the vertical position (lower clamp).

Position your workpiece correctly

CLAMPS

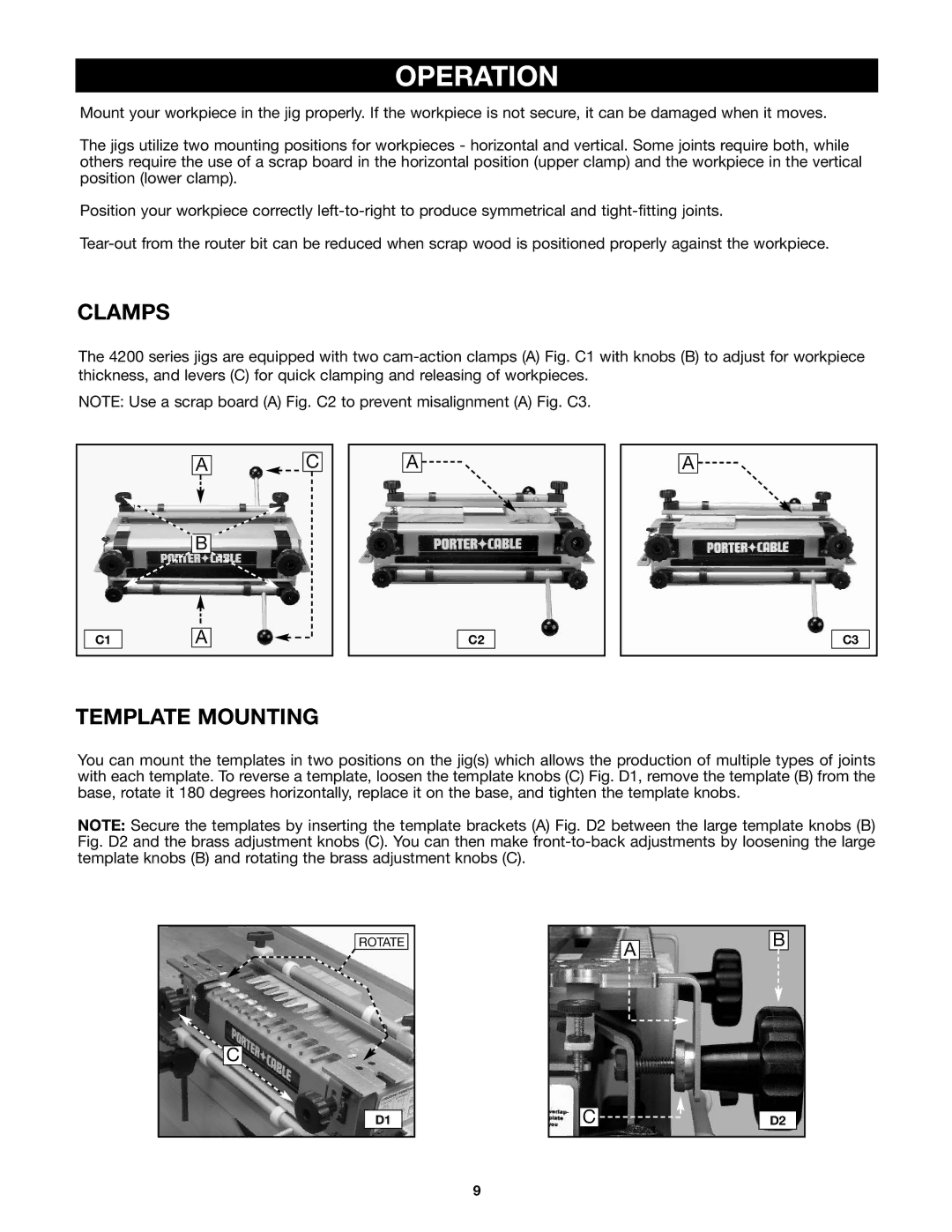

The 4200 series jigs are equipped with two

NOTE: Use a scrap board (A) Fig. C2 to prevent misalignment (A) Fig. C3.

| A | C |

| B |

|

C1 | A |

|

A ![]()

![]()

C2

A ![]()

![]()

C3

TEMPLATE MOUNTING

You can mount the templates in two positions on the jig(s) which allows the production of multiple types of joints with each template. To reverse a template, loosen the template knobs (C) Fig. D1, remove the template (B) from the base, rotate it 180 degrees horizontally, replace it on the base, and tighten the template knobs.

NOTE: Secure the templates by inserting the template brackets (A) Fig. D2 between the large template knobs (B) Fig. D2 and the brass adjustment knobs (C). You can then make

ROTATE |

C |

D1 |

A

C ![]()

![]()

![]()

B

D2

9