END SHAPING

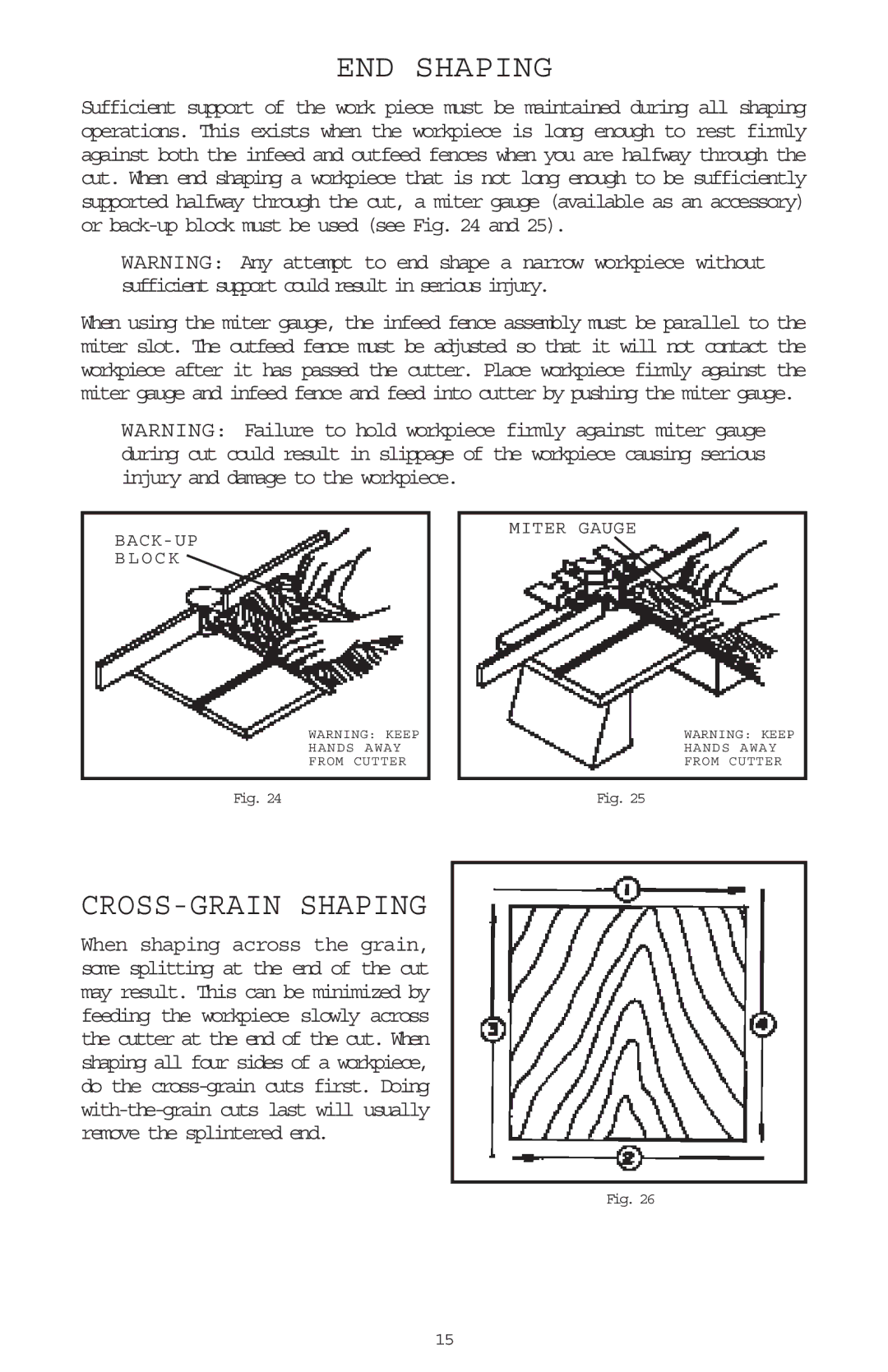

Sufficient support of the work piece must be maintained during all shaping operations. This exists when the workpiece is long enough to rest firmly against both the infeed and outfeed fences when you are halfway through the cut. When end shaping a workpiece that is not long enough to be sufficiently supported halfway through the cut, a miter gauge (available as an accessory) or

WARNING: Any attempt to end shape a narrow workpiece without sufficient support could result in serious injury.

When using the miter gauge, the infeed fence assembly must be parallel to the miter slot. The outfeed fence must be adjusted so that it will not contact the workpiece after it has passed the cutter. Place workpiece firmly against the miter gauge and infeed fence and feed into cutter by pushing the miter gauge.

WARNING: Failure to hold workpiece firmly against miter gauge during cut could result in slippage of the workpiece causing serious injury and damage to the workpiece.

MITER GAUGE

WARNING: KEEP

HANDS AWAY

FROM CUTTER

Fig. 24

WARNING: KEEP

HANDS AWAY

FROM CUTTER

Fig. 25

CROSS-GRAIN SHAPING

When shaping across the grain, some splitting at the end of the cut may result. This can be minimized by feeding the workpiece slowly across the cutter at the end of the cut. When shaping all four sides of a workpiece, do the

Fig. 26

15