6.NEVER RUN STOCK between fence and cutter.

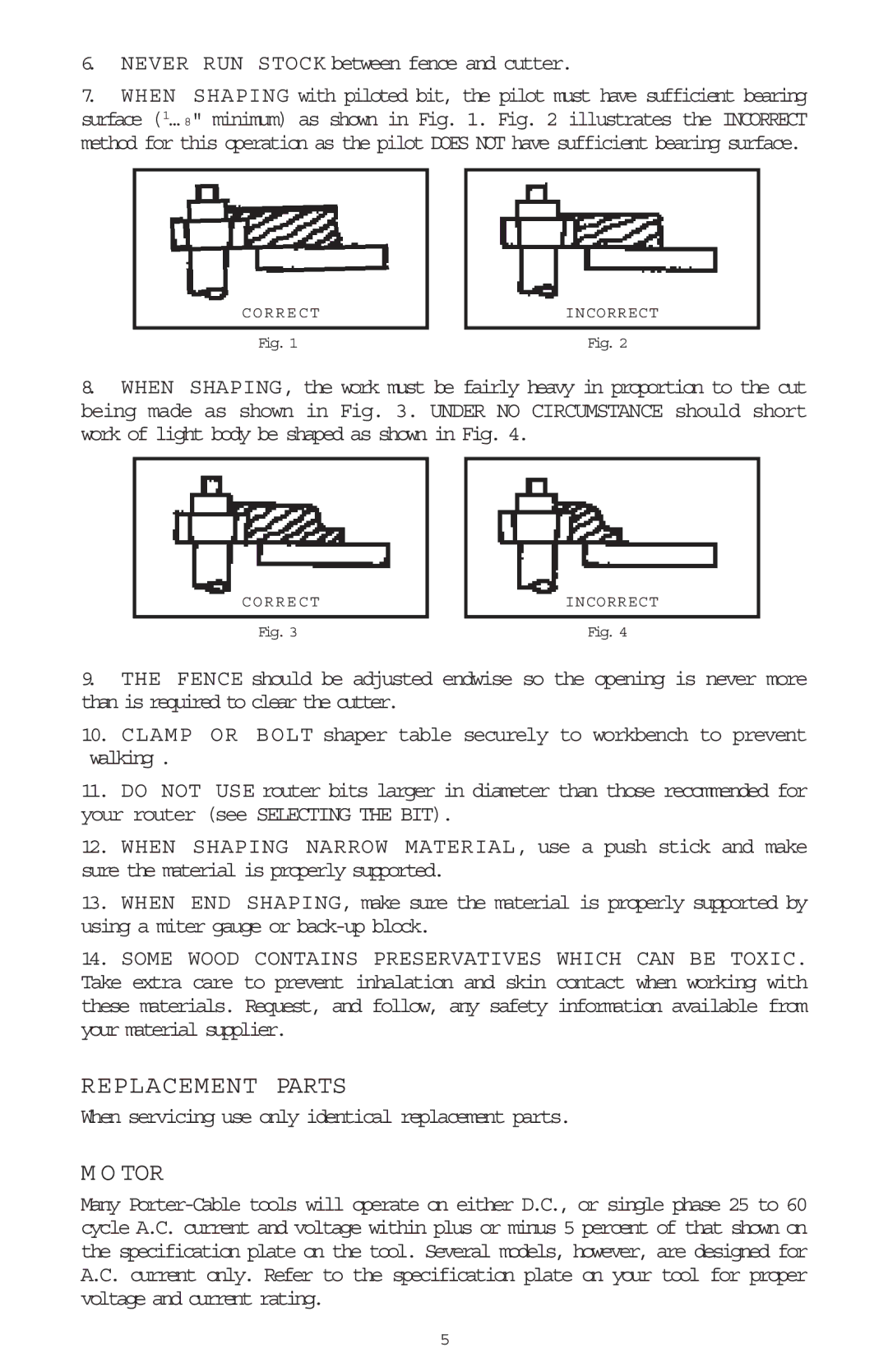

7.WHEN SHAPING with piloted bit, the pilot must have sufficient bearing surface (1… 8" minimum) as shown in Fig. 1. Fig. 2 illustrates the INCORRECT method for this operation as the pilot DOES NOT have sufficient bearing surface.

CORRECT

Fig. 1

INCORRECT

Fig. 2

8.WHEN SHAPING, the work must be fairly heavy in proportion to the cut being made as shown in Fig. 3. UNDER NO CIRCUMSTANCE should short work of light body be shaped as shown in Fig. 4.

CORRECT

Fig. 3

INCORRECT

Fig. 4

9.THE FENCE should be adjusted endwise so the opening is never more than is required to clear the cutter.

10.CLAMP OR BOLT shaper table securely to workbench to prevent walking .

11.DO NOT USE router bits larger in diameter than those recommended for your router (see SELECTING THE BIT).

12.WHEN SHAPING NARROW MATERIAL, use a push stick and make sure the material is properly supported.

13.WHEN END SHAPING, make sure the material is properly supported by using a miter gauge or

14.SOME WOOD CONTAINS PRESERVATIVES WHICH CAN BE TOXIC. Take extra care to prevent inhalation and skin contact when working with these materials. Request, and follow, any safety information available from your material supplier.

REPLACEMENT PARTS

When servicing use only identical replacement parts.

M O TOR

Many

5