G

Fig. 4

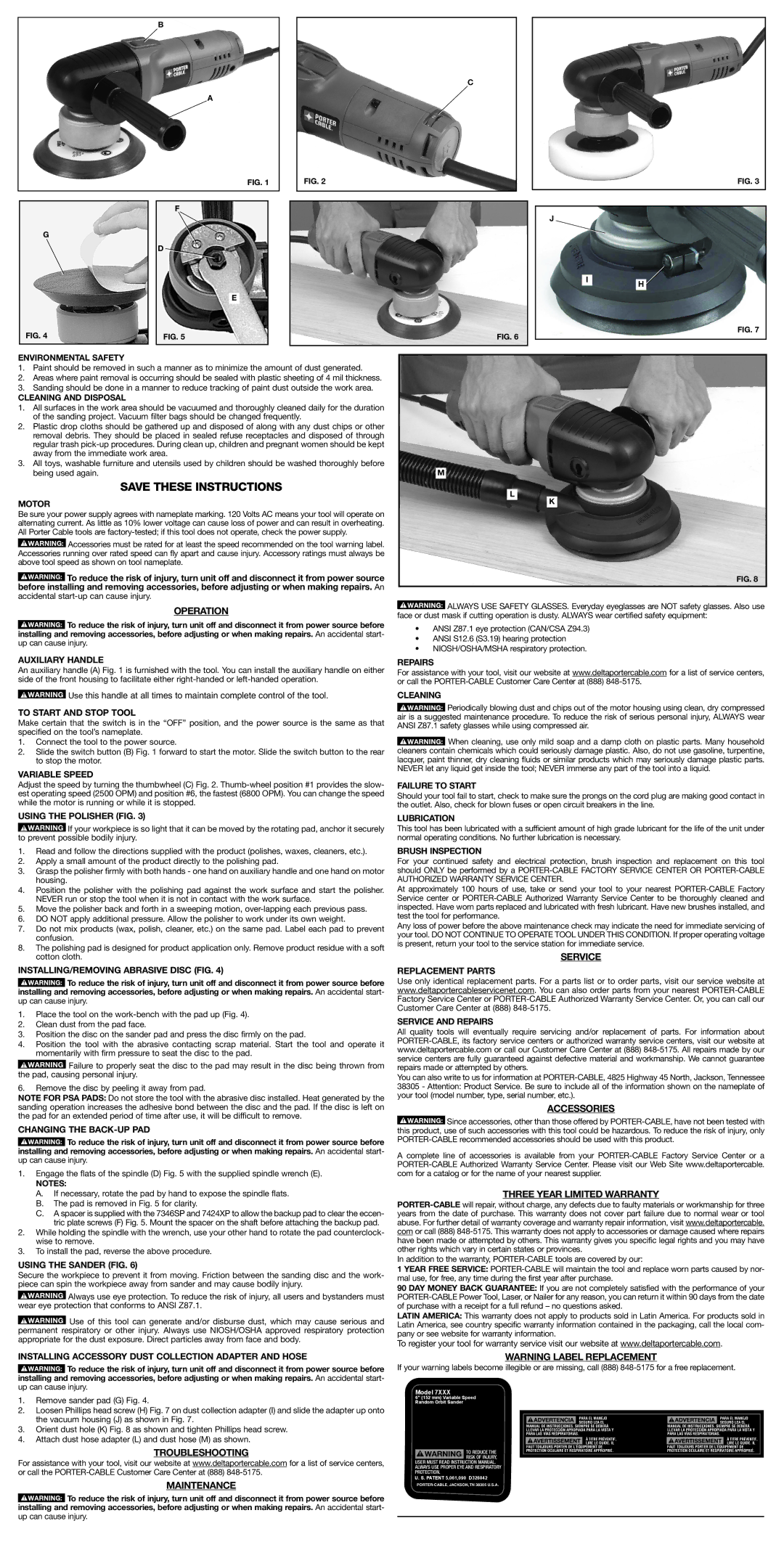

B

A

Fig. 1

F

D

E

Fig. 5

C

Fig. 2

Fig. 6

Fig. 3

J

IH![]()

Fig. 7

ENVIRONMENTAL SAFETY

1.Paint should be removed in such a manner as to minimize the amount of dust generated.

2.Areas where paint removal is occurring should be sealed with plastic sheeting of 4 mil thickness.

3.Sanding should be done in a manner to reduce tracking of paint dust outside the work area.

Cleaning and Disposal

1.All surfaces in the work area should be vacuumed and thoroughly cleaned daily for the duration of the sanding project. Vacuum filter bags should be changed frequently.

2.Plastic drop cloths should be gathered up and disposed of along with any dust chips or other removal debris. They should be placed in sealed refuse receptacles and disposed of through regular trash

3.All toys, washable furniture and utensils used by children should be washed thoroughly before being used again.

Save these instructions

MOTOR

Be sure your power supply agrees with nameplate marking. 120 Volts AC means your tool will operate on alternating current. As little as 10% lower voltage can cause loss of power and can result in overheating. All Porter Cable tools are

![]() Accessories must be rated for at least the speed recommended on the tool warning label. Accessories running over rated speed can fly apart and cause injury. Accessory ratings must always be above tool speed as shown on tool nameplate.

Accessories must be rated for at least the speed recommended on the tool warning label. Accessories running over rated speed can fly apart and cause injury. Accessory ratings must always be above tool speed as shown on tool nameplate.

![]() To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental

OPERATION

![]() To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental start- up can cause injury.

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental start- up can cause injury.

AUXILIARY HANDLE

An auxiliary handle (A) Fig. 1 is furnished with the tool. You can install the auxiliary handle on either side of the front housing to facilitate either

![]() Use this handle at all times to maintain complete control of the tool.

Use this handle at all times to maintain complete control of the tool.

TO START AND STOP Tool

Make certain that the switch is in the “OFF” position, and the power source is the same as that specified on the tool’s nameplate.

1.Connect the tool to the power source.

2.Slide the switch button (B) Fig. 1 forward to start the motor. Slide the switch button to the rear to stop the motor.

VARIABLE SPEED

Adjust the speed by turning the thumbwheel (C) Fig. 2.

USING THE POLISHER (FIG. 3)

![]() If your workpiece is so light that it can be moved by the rotating pad, anchor it securely to prevent possible bodily injury.

If your workpiece is so light that it can be moved by the rotating pad, anchor it securely to prevent possible bodily injury.

1.Read and follow the directions supplied with the product (polishes, waxes, cleaners, etc.).

2.Apply a small amount of the product directly to the polishing pad.

3.Grasp the polisher firmly with both hands - one hand on auxiliary handle and one hand on motor housing.

4.Position the polisher with the polishing pad against the work surface and start the polisher. NEVER run or stop the tool when it is not in contact with the work surface.

5.Move the polisher back and forth in a sweeping motion,

6.DO NOT apply additional pressure. Allow the polisher to work under its own weight.

7.Do not mix products (wax, polish, cleaner, etc.) on the same pad. Label each pad to prevent confusion.

8.The polishing pad is designed for product application only. Remove product residue with a soft cotton cloth.

INSTALLING/REMOVING ABRASIVE DISC (FIG. 4)

![]() To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental start- up can cause injury.

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental start- up can cause injury.

1.Place the tool on the

2.Clean dust from the pad face.

3.Position the disc on the sander pad and press the disc firmly on the pad.

4.Position the tool with the abrasive contacting scrap material. Start the tool and operate it momentarily with firm pressure to seat the disc to the pad.

![]() Failure to properly seat the disc to the pad may result in the disc being thrown from the pad, causing personal injury.

Failure to properly seat the disc to the pad may result in the disc being thrown from the pad, causing personal injury.

6.Remove the disc by peeling it away from pad.

NOTE FOR PSA PADS: Do not store the tool with the abrasive disc installed. Heat generated by the sanding operation increases the adhesive bond between the disc and the pad. If the disc is left on the pad for an extended period of time after use, it will be difficult to remove.

CHANGING THE BACK-UP PAD

![]() To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental start- up can cause injury.

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental start- up can cause injury.

1.Engage the flats of the spindle (D) Fig. 5 with the supplied spindle wrench (E).

Notes:

A.If necessary, rotate the pad by hand to expose the spindle flats.

B.The pad is removed in Fig. 5 for clarity.

C.A spacer is supplied with the 7346SP and 7424XP to allow the backup pad to clear the eccen- tric plate screws (F) Fig. 5. Mount the spacer on the shaft before attaching the backup pad.

2.While holding the spindle with the wrench, use your other hand to rotate the pad counterclock- wise to remove.

3.To install the pad, reverse the above procedure.

USING THE SANDER (FIG. 6)

Secure the workpiece to prevent it from moving. Friction between the sanding disc and the work- piece can spin the workpiece away from sander and may cause bodily injury.

![]() Always use eye protection. To reduce the risk of injury, all users and bystanders must wear eye protection that conforms to ANSI Z87.1.

Always use eye protection. To reduce the risk of injury, all users and bystanders must wear eye protection that conforms to ANSI Z87.1.

![]() Use of this tool can generate and/or disburse dust, which may cause serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

Use of this tool can generate and/or disburse dust, which may cause serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

INSTALLING ACCESSORY DUST COLLECTION ADAPTER AND HOSE

![]() To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental start- up can cause injury.

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental start- up can cause injury.

1.Remove sander pad (G) Fig. 4.

2.Loosen Phillips head screw (H) Fig. 7 on dust collection adapter (I) and slide the adapter up onto the vacuum housing (J) as shown in Fig. 7.

3.Orient dust hole (K) Fig. 8 as shown and tighten Phillips head screw.

4.Attach dust hose adapter (L) and dust hose (M) as shown.

TROUBLESHOOTING

For assistance with your tool, visit our website at www.deltaportercable.com for a list of service centers, or call the

MAINTENANCE

M

L

K

Fig. 8

![]() ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT safety glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS wear certified safety equipment:

ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT safety glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS wear certified safety equipment:

•ANSI Z87.1 eye protection (CAN/CSA Z94.3)

•ANSI S12.6 (S3.19) hearing protection

•NIOSH/OSHA/MSHA respiratory protection.

REPAIRS

For assistance with your tool, visit our website at www.deltaportercable.com for a list of service centers, or call the

CLEANING

![]() Periodically blowing dust and chips out of the motor housing using clean, dry compressed air is a suggested maintenance procedure. To reduce the risk of serious personal injury, ALWAYS wear ANSI Z87.1 safety glasses while using compressed air.

Periodically blowing dust and chips out of the motor housing using clean, dry compressed air is a suggested maintenance procedure. To reduce the risk of serious personal injury, ALWAYS wear ANSI Z87.1 safety glasses while using compressed air.

![]() When cleaning, use only mild soap and a damp cloth on plastic parts. Many household cleaners contain chemicals which could seriously damage plastic. Also, do not use gasoline, turpentine, lacquer, paint thinner, dry cleaning fluids or similar products which may seriously damage plastic parts. Never let any liquid get inside the tool; never immerse any part of the tool into a liquid.

When cleaning, use only mild soap and a damp cloth on plastic parts. Many household cleaners contain chemicals which could seriously damage plastic. Also, do not use gasoline, turpentine, lacquer, paint thinner, dry cleaning fluids or similar products which may seriously damage plastic parts. Never let any liquid get inside the tool; never immerse any part of the tool into a liquid.

FAILURE TO START

Should your tool fail to start, check to make sure the prongs on the cord plug are making good contact in the outlet. Also, check for blown fuses or open circuit breakers in the line.

LUBRICATION

This tool has been lubricated with a sufficient amount of high grade lubricant for the life of the unit under normal operating conditions. No further lubrication is necessary.

BRUSH INSPECTION

For your continued safety and electrical protection, brush inspection and replacement on this tool should ONLY be performed by a

At approximately 100 hours of use, take or send your tool to your nearest

Any loss of power before the above maintenance check may indicate the need for immediate servicing of your tool. DO NOT CONTINUE TO OPERATE TOOL UNDER THIS CONDITION. If proper operating voltage is present, return your tool to the service station for immediate service.

SERVICE

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our service website at www.deltaportercableservicenet.com. You can also order parts from your nearest

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information about

You can also write to us for information at

ACCESSORIES

![]() Since accessories, other than those offered by

Since accessories, other than those offered by

A complete line of accessories is available from your

Three Year Limited Warranty

In addition to the warranty,

1 YEAR FREE SERVICE:

90 DAY MONEY BACK GUARANTEE: If you are not completely satisfied with the performance of your

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America, see country specific warranty information contained in the packaging, call the local com- pany or see website for warranty information.

To register your tool for warranty service visit our website at www.deltaportercable.com.

WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call (888)

Model 7XXX

6" (152 mm) Variable Speed Random Orbit Sander

|

|

|

|

|

|

|

| PARA EL MANEJO |

|

|

|

| PARA EL MANEJO | ||

|

|

|

|

|

|

|

| SEGURO LEA EL |

|

|

|

| SEGURO LEA EL | ||

|

|

|

| MANUAL DE INSTRUCCIONES. SIEMPRE SE DEBERÁ | MANUAL DE INSTRUCCIONES. SIEMPRE SE DEBERÁ | ||||||||||

|

|

|

| LLEVAR LA PROTECCIÓN APROPIADA PARA LA VISTA Y | LLEVAR LA PROTECCIÓN APROPIADA PARA LA VISTA Y | ||||||||||

|

|

|

| PARA LAS VÍAS RESPIRATORIAS. | PARA LAS VÍAS RESPIRATORIAS. | ||||||||||

|

|

|

|

|

|

|

|

| À TITRE PRÉVENTIF, |

|

|

|

|

| À TITRE PRÉVENTIF, |

|

|

|

|

|

|

|

|

| LIRE LE GUIDE. IL |

|

|

|

|

| LIRE LE GUIDE. IL |

|

|

|

| FAUT TOUJOURS PORTER DE L’ÉQUIPEMENT DE | FAUT TOUJOURS PORTER DE L’ÉQUIPEMENT DE | ||||||||||

|

| TO REDUCE THE |

| PROTECTION OCULAIRE ET RESPIRATOIRE APPROPRIÉ. | PROTECTION OCULAIRE ET RESPIRATOIRE APPROPRIÉ. | ||||||||||

|

| RISK OF INJURY, |

|

|

|

|

|

|

|

|

|

|

|

|

|

USER MUST READ INSTRUCTION MANUAL. |

|

|

|

|

|

|

|

|

|

|

|

| |||

ALWAYS USE PROPER EYE AND RESPIRATORY |

|

|

|

|

|

|

|

|

|

|

|

| |||

PROTECTION. |

|

|

|

|

|

|

|

|

|

|

|

| |||

U. S. PATENT 5,061,090 D326042

![]() To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental start- up can cause injury.

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental start- up can cause injury.