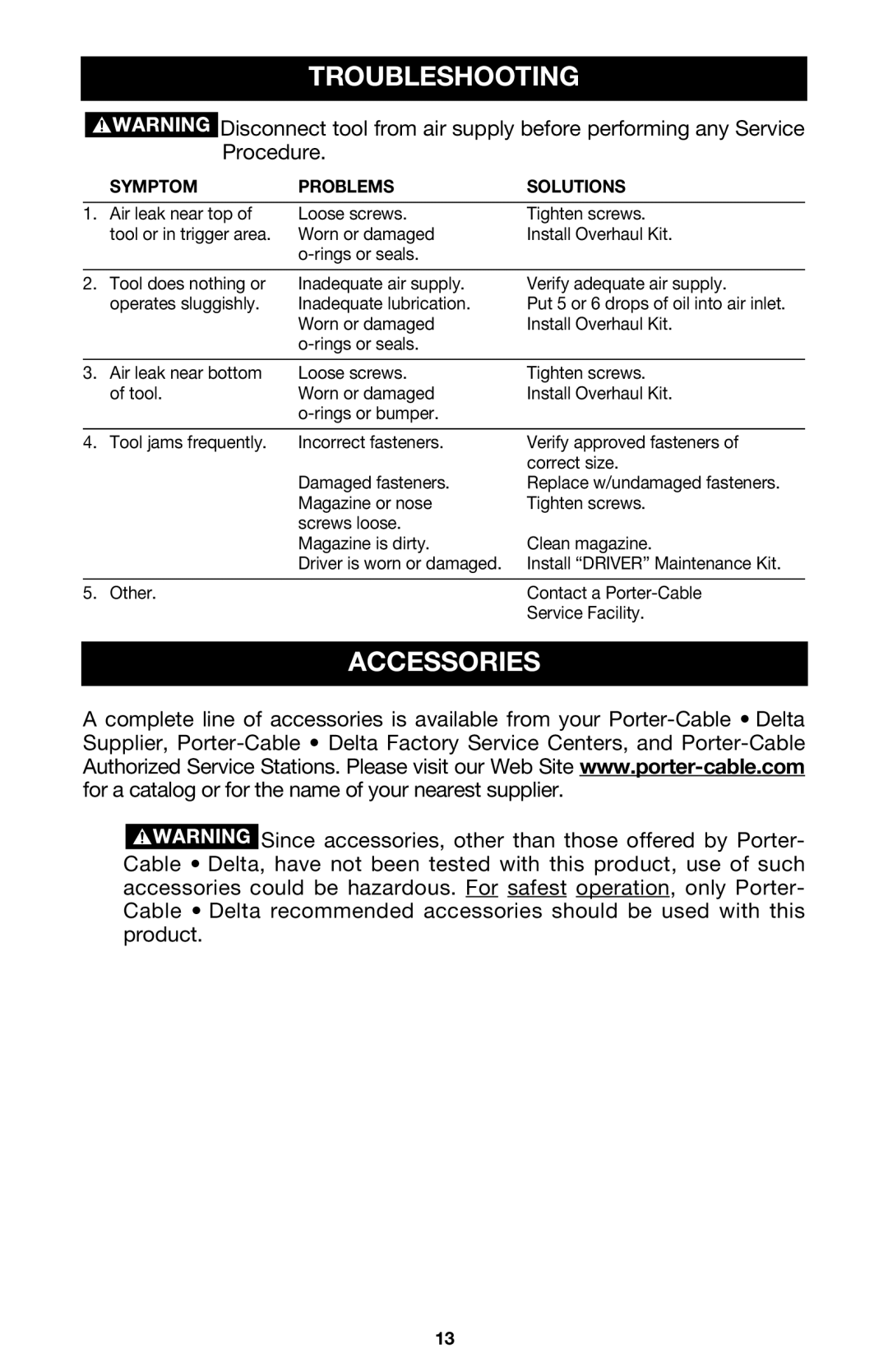

TROUBLESHOOTING

Disconnect tool from air supply before performing any Service Procedure.

SYMPTOM | PROBLEMS | SOLUTIONS |

1.Air leak near top of tool or in trigger area.

Loose screws. | Tighten screws. |

Worn or damaged | Install Overhaul Kit. |

|

2.Tool does nothing or operates sluggishly.

Inadequate air supply. | Verify adequate air supply. |

Inadequate lubrication. | Put 5 or 6 drops of oil into air inlet. |

Worn or damaged | Install Overhaul Kit. |

|

3.Air leak near bottom of tool.

Loose screws. | Tighten screws. |

Worn or damaged | Install Overhaul Kit. |

|

4. | Tool jams frequently. | Incorrect fasteners. | Verify approved fasteners of |

|

|

| correct size. |

|

| Damaged fasteners. | Replace w/undamaged fasteners. |

|

| Magazine or nose | Tighten screws. |

|

| screws loose. |

|

|

| Magazine is dirty. | Clean magazine. |

|

| Driver is worn or damaged. | Install “DRIVER” Maintenance Kit. |

|

|

|

|

5. | Other. |

| Contact a |

|

|

| Service Facility. |

ACCESSORIES

A complete line of accessories is available from your

![]() Since accessories, other than those offered by Porter- Cable • Delta, have not been tested with this product, use of such accessories could be hazardous. For safest operation, only Porter- Cable • Delta recommended accessories should be used with this product.

Since accessories, other than those offered by Porter- Cable • Delta, have not been tested with this product, use of such accessories could be hazardous. For safest operation, only Porter- Cable • Delta recommended accessories should be used with this product.

13