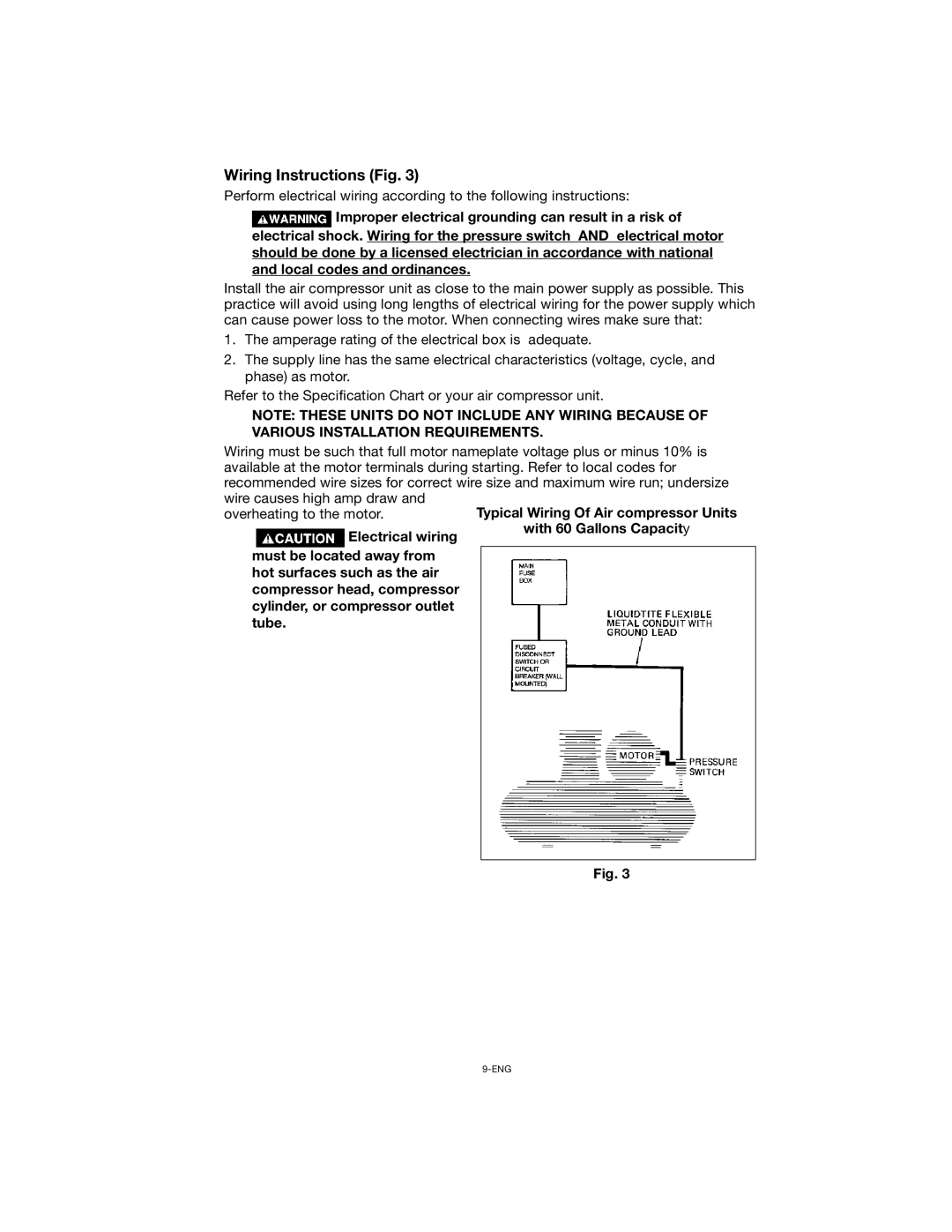

Wiring Instructions (Fig. 3)

Perform electrical wiring according to the following instructions:

![]() Improper electrical grounding can result in a risk of

Improper electrical grounding can result in a risk of

electrical shock. Wiring for the pressure switch AND electrical motor should be done by a licensed electrician in accordance with national and local codes and ordinances.

Install the air compressor unit as close to the main power supply as possible. This practice will avoid using long lengths of electrical wiring for the power supply which can cause power loss to the motor. When connecting wires make sure that:

1.The amperage rating of the electrical box is adequate.

2.The supply line has the same electrical characteristics (voltage, cycle, and phase) as motor.

Refer to the Specification Chart or your air compressor unit.

NOTE: THESE UNITS DO NOT INCLUDE ANY WIRING BECAUSE OF VARIOUS INSTALLATION REQUIREMENTS.

Wiring must be such that full motor nameplate voltage plus or minus 10% is available at the motor terminals during starting. Refer to local codes for recommended wire sizes for correct wire size and maximum wire run; undersize wire causes high amp draw and

overheating to the motor.

![]() Electrical wiring must be located away from hot surfaces such as the air compressor head, compressor cylinder, or compressor outlet tube.

Electrical wiring must be located away from hot surfaces such as the air compressor head, compressor cylinder, or compressor outlet tube.