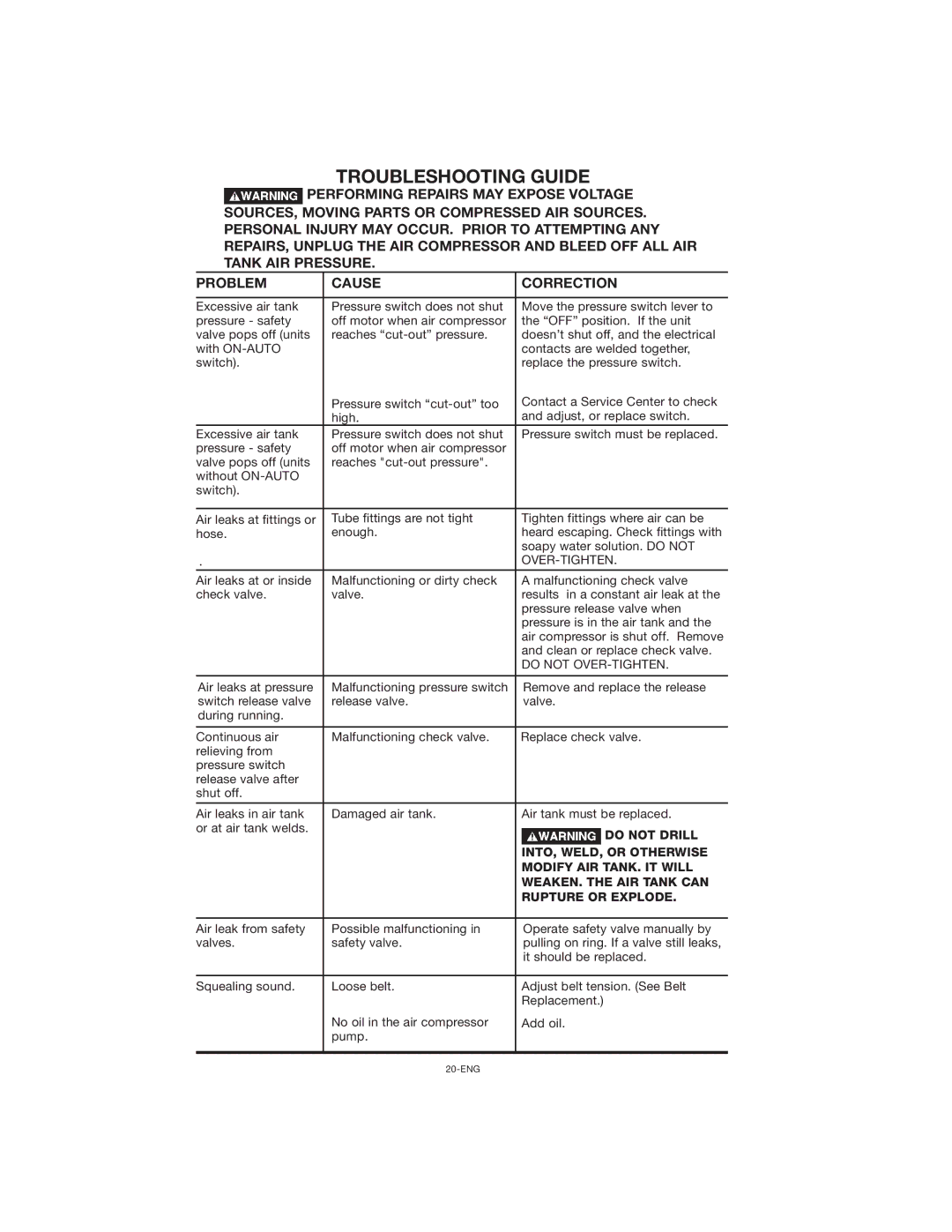

TROUBLESHOOTING GUIDE

![]() PERFORMING REPAIRS MAY EXPOSE VOLTAGE SOURCES, MOVING PARTS OR COMPRESSED AIR SOURCES. PERSONAL INJURY MAY OCCUR. PRIOR TO ATTEMPTING ANY REPAIRS, UNPLUG THE AIR COMPRESSOR AND BLEED OFF ALL AIR TANK AIR PRESSURE.

PERFORMING REPAIRS MAY EXPOSE VOLTAGE SOURCES, MOVING PARTS OR COMPRESSED AIR SOURCES. PERSONAL INJURY MAY OCCUR. PRIOR TO ATTEMPTING ANY REPAIRS, UNPLUG THE AIR COMPRESSOR AND BLEED OFF ALL AIR TANK AIR PRESSURE.

PROBLEM | CAUSE | CORRECTION |

|

|

|

Excessive air tank | Pressure switch does not shut | Move the pressure switch lever to |

pressure - safety | off motor when air compressor | the “OFF” position. If the unit |

valve pops off (units | reaches | doesn’t shut off, and the electrical |

with |

| contacts are welded together, |

switch). |

| replace the pressure switch. |

| Pressure switch | Contact a Service Center to check |

| high. | and adjust, or replace switch. |

Excessive air tank | Pressure switch does not shut | Pressure switch must be replaced. |

pressure - safety | off motor when air compressor |

|

valve pops off (units | reaches |

|

without |

|

|

switch). |

|

|

|

|

|

Air leaks at fittings or | Tube fittings are not tight | Tighten fittings where air can be |

hose. | enough. | heard escaping. Check fittings with |

|

| soapy water solution. DO NOT |

. |

|

|

Air leaks at or inside | Malfunctioning or dirty check | A malfunctioning check valve |

check valve. | valve. | results in a constant air leak at the |

|

| pressure release valve when |

|

| pressure is in the air tank and the |

|

| air compressor is shut off. Remove |

|

| and clean or replace check valve. |

|

| DO NOT |

|

|

|

Air leaks at pressure | Malfunctioning pressure switch | Remove and replace the release |

switch release valve | release valve. | valve. |

during running. |

|

|

|

|

|

Continuous air | Malfunctioning check valve. | Replace check valve. |

relieving from |

|

|

pressure switch |

|

|

release valve after |

|

|

shut off. |

|

|

|

|

|

Air leaks in air tank | Damaged air tank. | Air tank must be replaced. |

or at air tank welds. |

| DO NOT DRILL |

|

| |

|

| INTO, WELD, OR OTHERWISE |

|

| MODIFY AIR TANK. IT WILL |

|

| WEAKEN. THE AIR TANK CAN |

|

| RUPTURE OR EXPLODE. |

|

|

|

Air leak from safety | Possible malfunctioning in | Operate safety valve manually by |

valves. | safety valve. | pulling on ring. If a valve still leaks, |

|

| it should be replaced. |

|

|

|

Squealing sound. | Loose belt. | Adjust belt tension. (See Belt |

|

| Replacement.) |

| No oil in the air compressor | Add oil. |

| pump. |

|

|

|

|