INSTALLATION

![]() Improper electrical installation of this product may void its warranty and your fire insurance. Have circuit wiring performed by qualified personnel such as a licensed electricians who is familiar with the current national electrical code and any prevailing local electrical codes.

Improper electrical installation of this product may void its warranty and your fire insurance. Have circuit wiring performed by qualified personnel such as a licensed electricians who is familiar with the current national electrical code and any prevailing local electrical codes.

Location of the Air Compressor

![]() The manifold assembly does not provide adequate stability or support for lifting the unit. If the unit must be moved, use the air tank for lifting.

The manifold assembly does not provide adequate stability or support for lifting the unit. If the unit must be moved, use the air tank for lifting.

Operate the air compressor in a clean, dry, and

The flywheel side of the unit should be placed toward the wall and protected with a totally enclosed belt guard. The area should allow space on all sides for air circulation and for ease of normal maintenance. Keep the unit away from areas which have dirt, vapor, and combustible fumes in the atmosphere which may clog and gum the intake filter and valves, causing inefficient operation.

If humidity is high, an air filter can be installed in line to remove excessive moisture. Closely follow instructions packaged with the filter for proper installation. It must be installed as close as possible to the accessory.

The air compressor should be as near to air outlets as possible in order to avoid long pipe lines. Do not place the air compressor where heat is excessive.

Do not use an extension cord. To avoid voltage drop and power loss to the motor, use extra air hose instead of an extension cord.

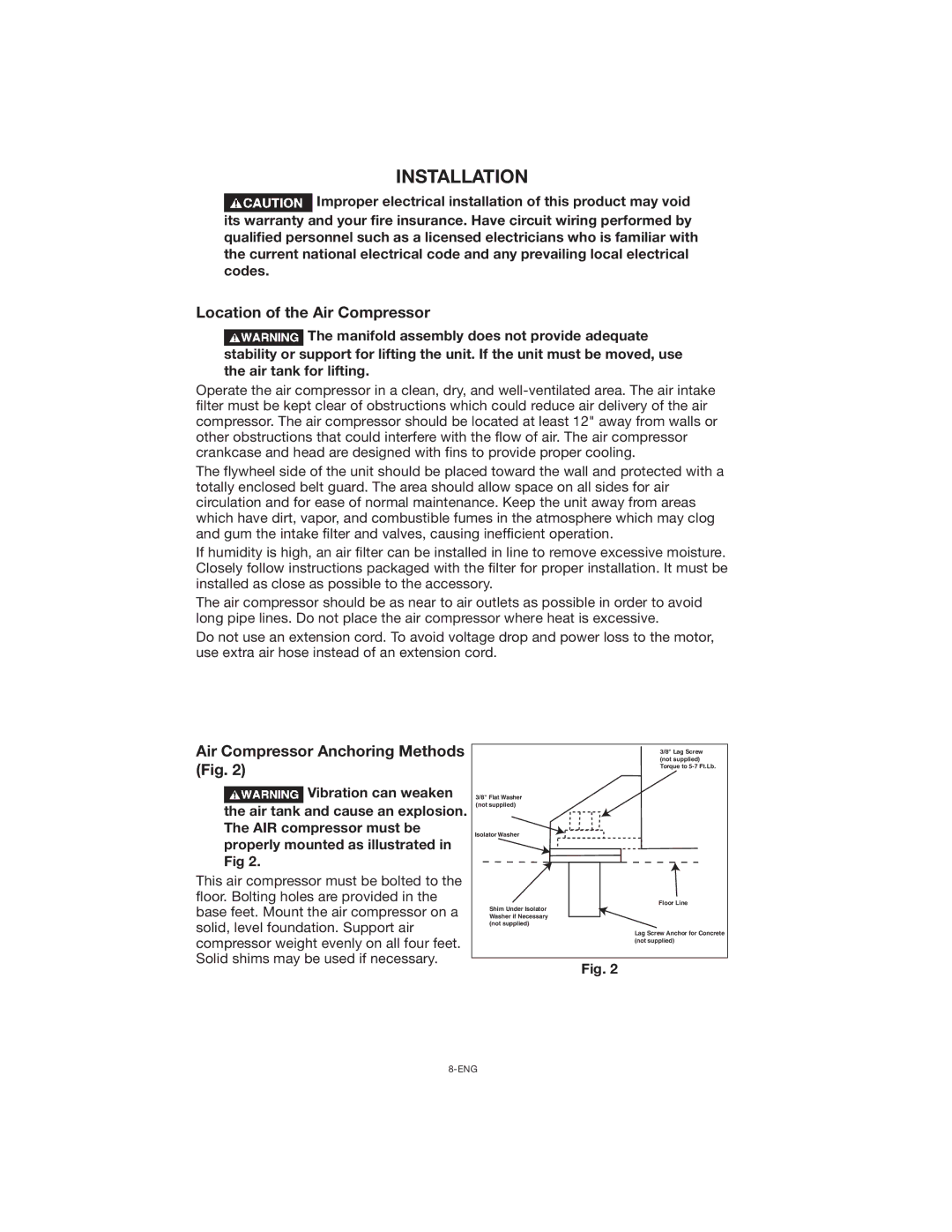

Air Compressor Anchoring Methods (Fig. 2)

![]() Vibration can weaken the air tank and cause an explosion. The AIR compressor must be properly mounted as illustrated in Fig 2.

Vibration can weaken the air tank and cause an explosion. The AIR compressor must be properly mounted as illustrated in Fig 2.

This air compressor must be bolted to the floor. Bolting holes are provided in the base feet. Mount the air compressor on a solid, level foundation. Support air compressor weight evenly on all four feet. Solid shims may be used if necessary.

3/8" Lag Screw (not supplied) Torque to

3/8" Flat Washer (not supplied)

Isolator Washer

Floor Line

Shim Under Isolator Washer if Necessary (not supplied)

Lag Screw Anchor for Concrete (not supplied)

Fig. 2