DA250B specifications

The Porter-Cable DA250B is a well-regarded tool in the world of pneumatic nailers, designed for those seeking efficiency, precision, and durability in their projects. This particular model is an 18-gauge brad nailer that excels in a variety of applications, such as trim work, cabinetry, and light woodworking. Its lightweight design and user-friendly features make it a popular choice among both professional contractors and DIY enthusiasts.One of the standout characteristics of the DA250B is its powerful motor that drives nails from 5/8 inch to 2 inches in length. This range allows users to tackle a wide array of tasks, from affixing delicate trim to securing more substantial materials. The tool’s capacity to shoot brads at a rapid rate significantly enhances productivity, allowing projects to move forward without unnecessary delays.

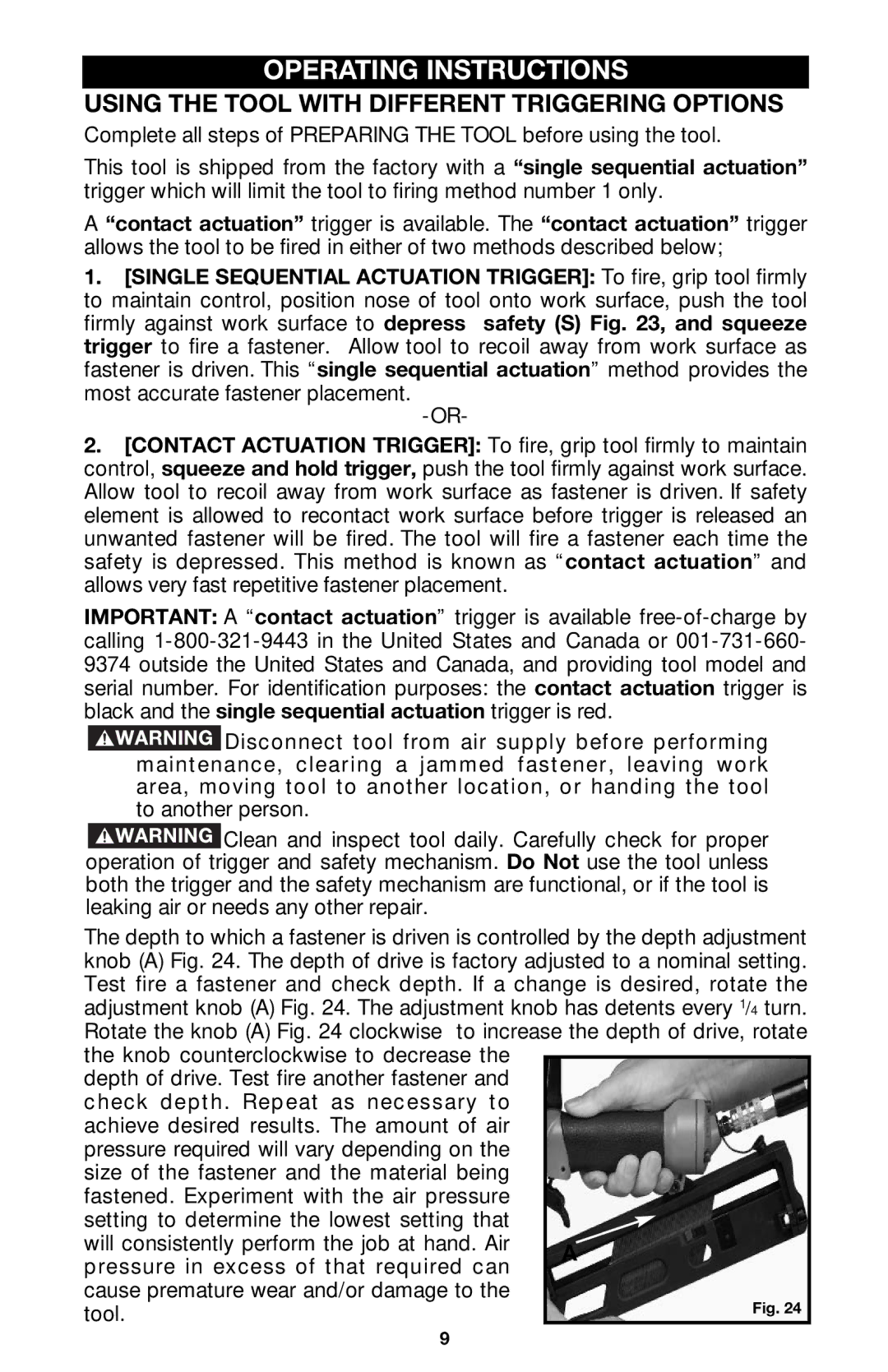

The DA250B is equipped with a tool-free depth-of-drive adjustment feature, allowing users to easily adjust the depth of the nail without the use of additional tools. This ensures consistent results and minimizes the risk of over-driving or under-driving nails, both of which can compromise the aesthetic and structural integrity of finished work.

Another impressive feature is its integrated rear exhaust that effectively directs air away from the user and work surface, helping to keep both clean during operation. This design consideration is particularly important in a working environment where visibility and cleanliness are paramount.

The nailer also boasts a lightweight construction, weighing in at just over 3 pounds, which reduces user fatigue. The ergonomic grip and balanced design further enhance the comfort of the user during extended periods of work. Its robust aluminum housing adds to its durability, ensuring that the tool can withstand the rigors of frequent use on job sites.

Additionally, the DA250B incorporates a no-mar tip to prevent damage to the work surface, making it ideal for projects requiring a high level of finish quality. The magazine is easy to load, accommodating up to 100 brads, reducing downtime for reloading.

In conclusion, the Porter-Cable DA250B is a versatile, efficient, and durable brad nailer that offers an array of features designed to maximize productivity and ease of use. Its combination of power, precision, and user-friendly characteristics makes it a reliable choice for both professionals and hobbyists alike, ensuring that any project can be completed with confidence and finesse.