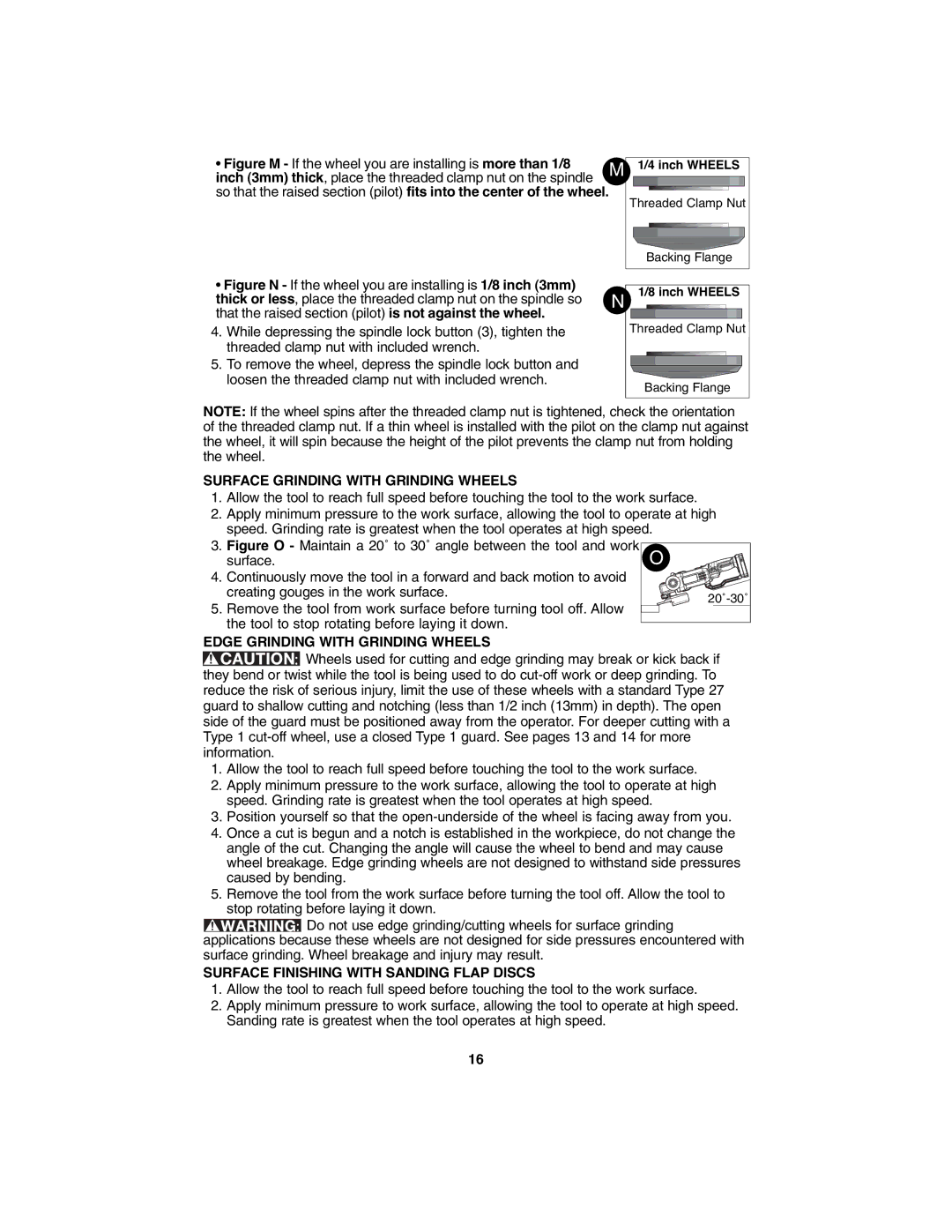

• Figure M - If the wheel you are installing is more than 1/8 | M 1/4 inch WHEELS |

inch (3mm) thick, place the threaded clamp nut on the spindle |

|

so that the raised section (pilot) fits into the center of the wheel. | |

| Threaded Clamp Nut |

| Backing Flange |

• Figure N - If the wheel you are installing is 1/8 inch (3mm) | N 1/8 inch WHEELS |

thick or less, place the threaded clamp nut on the spindle so | |

that the raised section (pilot) is not against the wheel. |

|

4. While depressing the spindle lock button (3), tighten the | Threaded Clamp Nut |

threaded clamp nut with included wrench. |

|

5. To remove the wheel, depress the spindle lock button and |

|

loosen the threaded clamp nut with included wrench. | Backing Flange |

| |

NOTE: If the wheel spins after the threaded clamp nut is tightened, check the orientation of the threaded clamp nut. If a thin wheel is installed with the pilot on the clamp nut against the wheel, it will spin because the height of the pilot prevents the clamp nut from holding the wheel.

SURFACE GRINDING WITH GRINDING WHEELS

1.Allow the tool to reach full speed before touching the tool to the work surface.

2.Apply minimum pressure to the work surface, allowing the tool to operate at high speed. Grinding rate is greatest when the tool operates at high speed.

3.Figure O - Maintain a 20˚ to 30˚ angle between the tool and work

| surface. | O | |

4. | Continuously move the tool in a forward and back motion to avoid |

| |

| creating gouges in the work surface. | ||

5. | Remove the tool from work surface before turning tool off. Allow | ||

| |||

| the tool to stop rotating before laying it down. |

|

EDGE GRINDING WITH GRINDING WHEELS

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() : Wheels used for cutting and edge grinding may break or kick back if they bend or twist while the tool is being used to do

: Wheels used for cutting and edge grinding may break or kick back if they bend or twist while the tool is being used to do

1.Allow the tool to reach full speed before touching the tool to the work surface.

2.Apply minimum pressure to the work surface, allowing the tool to operate at high speed. Grinding rate is greatest when the tool operates at high speed.

3.Position yourself so that the

4.Once a cut is begun and a notch is established in the workpiece, do not change the angle of the cut. Changing the angle will cause the wheel to bend and may cause wheel breakage. Edge grinding wheels are not designed to withstand side pressures caused by bending.

5.Remove the tool from the work surface before turning the tool off. Allow the tool to stop rotating before laying it down.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() : Do not use edge grinding/cutting wheels for surface grinding

: Do not use edge grinding/cutting wheels for surface grinding

applications because these wheels are not designed for side pressures encountered with surface grinding. Wheel breakage and injury may result.

SURFACE FINISHING WITH SANDING FLAP DISCS

1.Allow the tool to reach full speed before touching the tool to the work surface.

2.Apply minimum pressure to work surface, allowing the tool to operate at high speed. Sanding rate is greatest when the tool operates at high speed.

16