TROUBLESHOOTING GUIDE

!WARNING

To avoid injury from an accidental start, turn the switch OFF and always remove the plug from the power source before making any adjustments.

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our service website at www.portercable. com. You can also order parts from your nearest

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information about

You can also write to us for information at Power Tool Specialists, 684 Huey Road Rock Hill, SC 29704,

(888)

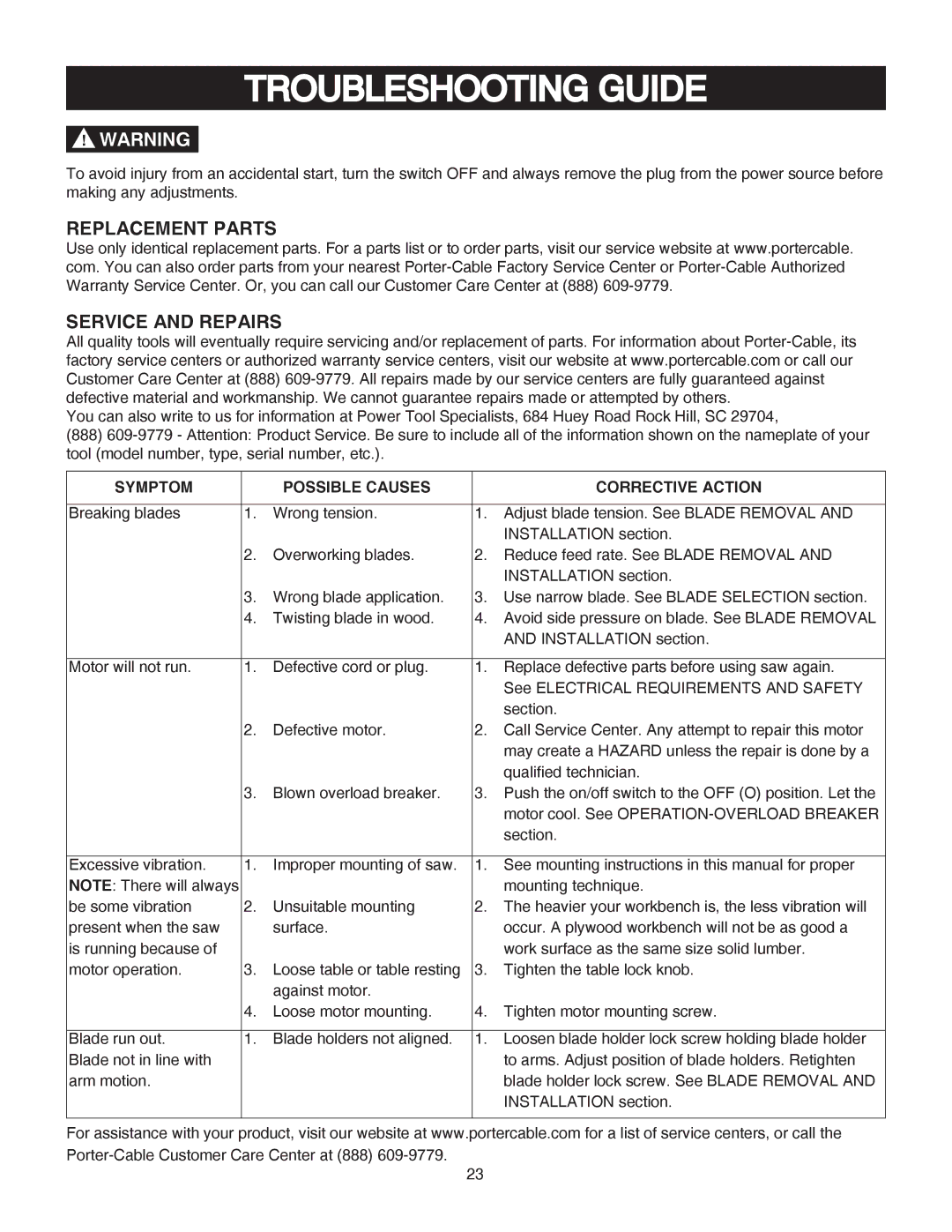

SYMPTOM |

| POSSIBLE CAUSES |

| CORRECTIVE ACTION |

|

|

|

|

|

Breaking blades | 1. | Wrong tension. | 1. | Adjust blade tension. See BLADE REMOVAL AND |

|

|

|

| INSTALLATION section. |

| 2. | Overworking blades. | 2. | Reduce feed rate. See BLADE REMOVAL AND |

|

|

|

| INSTALLATION section. |

| 3. | Wrong blade application. | 3. | Use narrow blade. See BLADE SELECTION section. |

| 4. | Twisting blade in wood. | 4. | Avoid side pressure on blade. See BLADE REMOVAL |

|

|

|

| AND INSTALLATION section. |

|

|

|

|

|

Motor will not run. | 1. | Defective cord or plug. | 1. | Replace defective parts before using saw again. |

|

|

|

| See ELECTRICAL REQUIREMENTS AND SAFETY |

|

|

|

| section. |

| 2. | Defective motor. | 2. | Call Service Center. Any attempt to repair this motor |

|

|

|

| may create a HAZARD unless the repair is done by a |

|

|

|

| qualified technician. |

| 3. | Blown overload breaker. | 3. | Push the on/off switch to the OFF (O) position. Let the |

|

|

|

| motor cool. See |

|

|

|

| section. |

|

|

|

|

|

Excessive vibration. | 1. | Improper mounting of saw. | 1. | See mounting instructions in this manual for proper |

NOTE: There will always |

|

|

| mounting technique. |

be some vibration | 2. | Unsuitable mounting | 2. | The heavier your workbench is, the less vibration will |

present when the saw |

| surface. |

| occur. A plywood workbench will not be as good a |

is running because of |

|

|

| work surface as the same size solid lumber. |

motor operation. | 3. | Loose table or table resting | 3. | Tighten the table lock knob. |

|

| against motor. |

|

|

| 4. | Loose motor mounting. | 4. | Tighten motor mounting screw. |

|

|

|

|

|

Blade run out. | 1. | Blade holders not aligned. | 1. | Loosen blade holder lock screw holding blade holder |

Blade not in line with |

|

|

| to arms. Adjust position of blade holders. Retighten |

arm motion. |

|

|

| blade holder lock screw. See BLADE REMOVAL AND |

|

|

|

| INSTALLATION section. |

|

|

|

|

|

For assistance with your product, visit our website at www.portercable.com for a list of service centers, or call the

23