release the fixing screw to adjust the position of sensor head. The acceptable paper roll bobbin outer diameter is between 18 and 22mm. This adjustment allows sensor activation on paper roll overall diameter between 21 and 23.6 mm unless for too light bobbins. Remember, for smaller roll diameter, the sensor head should go higher.

2.Paper roll placement

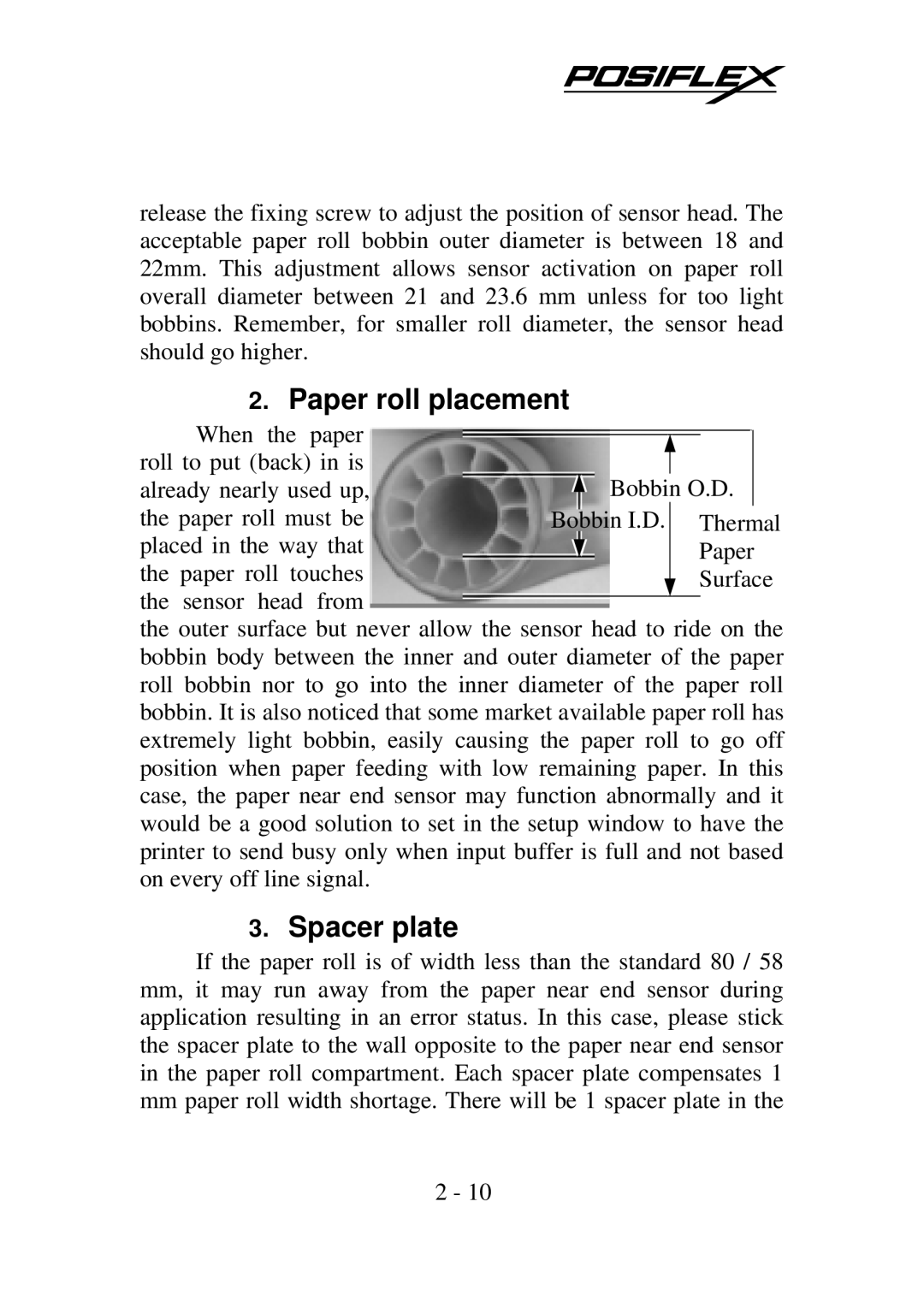

When the paper roll to put (back) in is already nearly used up,

the paper roll must be

placed in the way that the paper roll touches

the sensor head from

the outer surface but never allow the sensor head to ride on the bobbin body between the inner and outer diameter of the paper roll bobbin nor to go into the inner diameter of the paper roll bobbin. It is also noticed that some market available paper roll has extremely light bobbin, easily causing the paper roll to go off position when paper feeding with low remaining paper. In this case, the paper near end sensor may function abnormally and it would be a good solution to set in the setup window to have the printer to send busy only when input buffer is full and not based on every off line signal.

3.Spacer plate

If the paper roll is of width less than the standard 80 / 58 mm, it may run away from the paper near end sensor during application resulting in an error status. In this case, please stick the spacer plate to the wall opposite to the paper near end sensor in the paper roll compartment. Each spacer plate compensates 1

mmpaper roll width shortage. There will be 1 spacer plate in the

2 - 10