Bring the powerhead engine to cutting speed before entering the material to be cut.

If the blade does not turn when you squeeze the throttle trigger of the powerhead, make sure the attachment is fully inserted into the coupler.

Always release the throttle trigger and allow powerhead engine to return to idle speed when not cutting. The blade should not turn while the engine is running at idle. If the blade turns at idle, do not use your unit. Refer to the CARBURETOR ADJUSTMENT section of the powerhead manual or contact your autho- rized service dealer.

SMaintain good firm footing while using the unit. Do this by planting feet firmly in a com-

fortable apart position.

SCut while swinging the upper part of your body from left to right.

SAs you move forward to the next area to cut, be sure to maintain your balance, and footing.

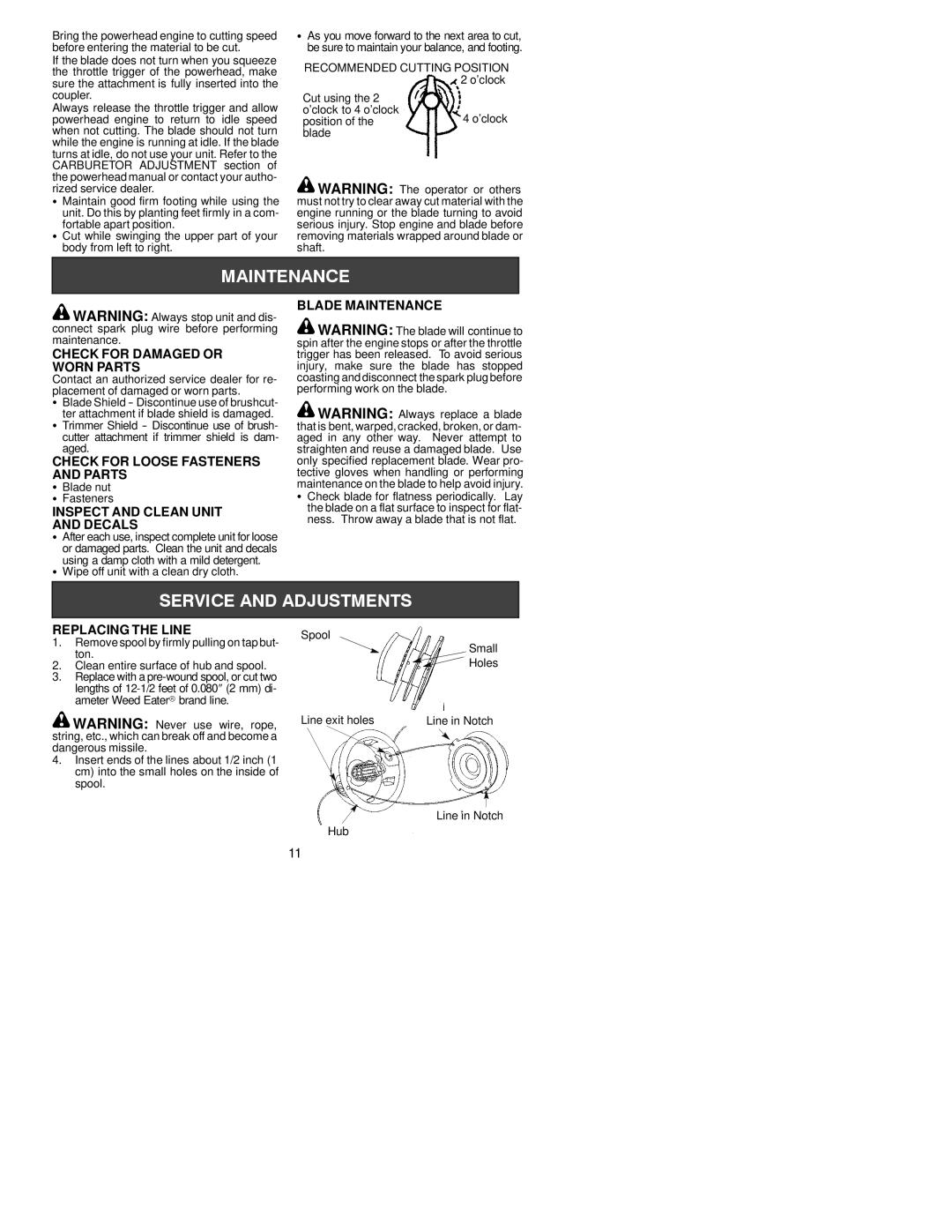

RECOMMENDED CUTTING POSITION

| 2 o’clock |

Cut using the 2 |

|

o’clock to 4 o’clock | 4 o’clock |

position of the | |

blade |

|

![]() WARNING: The operator or others must not try to clear away cut material with the engine running or the blade turning to avoid serious injury. Stop engine and blade before removing materials wrapped around blade or shaft.

WARNING: The operator or others must not try to clear away cut material with the engine running or the blade turning to avoid serious injury. Stop engine and blade before removing materials wrapped around blade or shaft.

WARNING: Always stop unit and dis- | BLADE MAINTENANCE | |

WARNING: The blade will continue to | ||

connect spark plug wire before performing | ||

maintenance. | spin after the engine stops or after the throttle | |

CHECK FOR DAMAGED OR | trigger has been released. To avoid serious | |

WORN PARTS | injury, make sure the blade has stopped | |

Contact an authorized service dealer for re- | coasting anddisconnect the spark plug before | |

placement of damaged or worn parts. | performing work on the blade. | |

S Blade Shield | WARNING: Always replace a blade | |

ter attachment if blade shield is damaged. | ||

S Trimmer Shield | that is bent, warped, cracked, broken, or dam- | |

cutter attachment if trimmer shield is dam- | aged in any other way. Never attempt to | |

aged. | straighten and reuse a damaged blade. Use | |

CHECK FOR LOOSE FASTENERS | only specified replacement blade. Wear pro- | |

AND PARTS | tective gloves when handling or performing | |

S Blade nut | maintenance on the blade to help avoid injury. | |

S Fasteners | S Check blade for flatness periodically. Lay | |

INSPECT AND CLEAN UNIT | the blade on a flat surface to inspect for flat- | |

AND DECALS | ness. Throw away a blade that is not flat. | |

S After each use, inspect complete unit for loose |

| |

or damaged parts. Clean the unit and decals |

|

using a damp cloth with a mild detergent.

SWipe off unit with a clean dry cloth.

REPLACING THE LINE | Spool | ||

1. | Remove spool by firmly pulling on tap but- | ||

Small | |||

| ton. | ||

| Holes | ||

2. | Clean entire surface of hub and spool. | ||

3.Replace with a

WARNING: Never use wire, rope, | Line exit holes |

|

| Line in Notch | ||

string, etc., which can break off and become a |

|

|

|

|

|

|

|

|

|

|

|

| |

dangerous missile. |

|

|

|

|

|

|

|

|

|

|

|

| |

4.Insert ends of the lines about 1/2 inch (1 cm) into the small holes on the inside of

spool.

Line in Notch

Hub

11