6.Make sure the coil spring cover is pushed back in, then tighten the two hex nuts (D). Do not over tighten. The hex nuts should be tightened against each other.

7.

On/Off Switch

Pull out the switch to start the drill press, push to stop.

The switch has a safety feature that prevents unauthorized or accidental starting of the drill press. With the switch in the "off" position, slide out the switch safety key (Figure 20). This piece must be

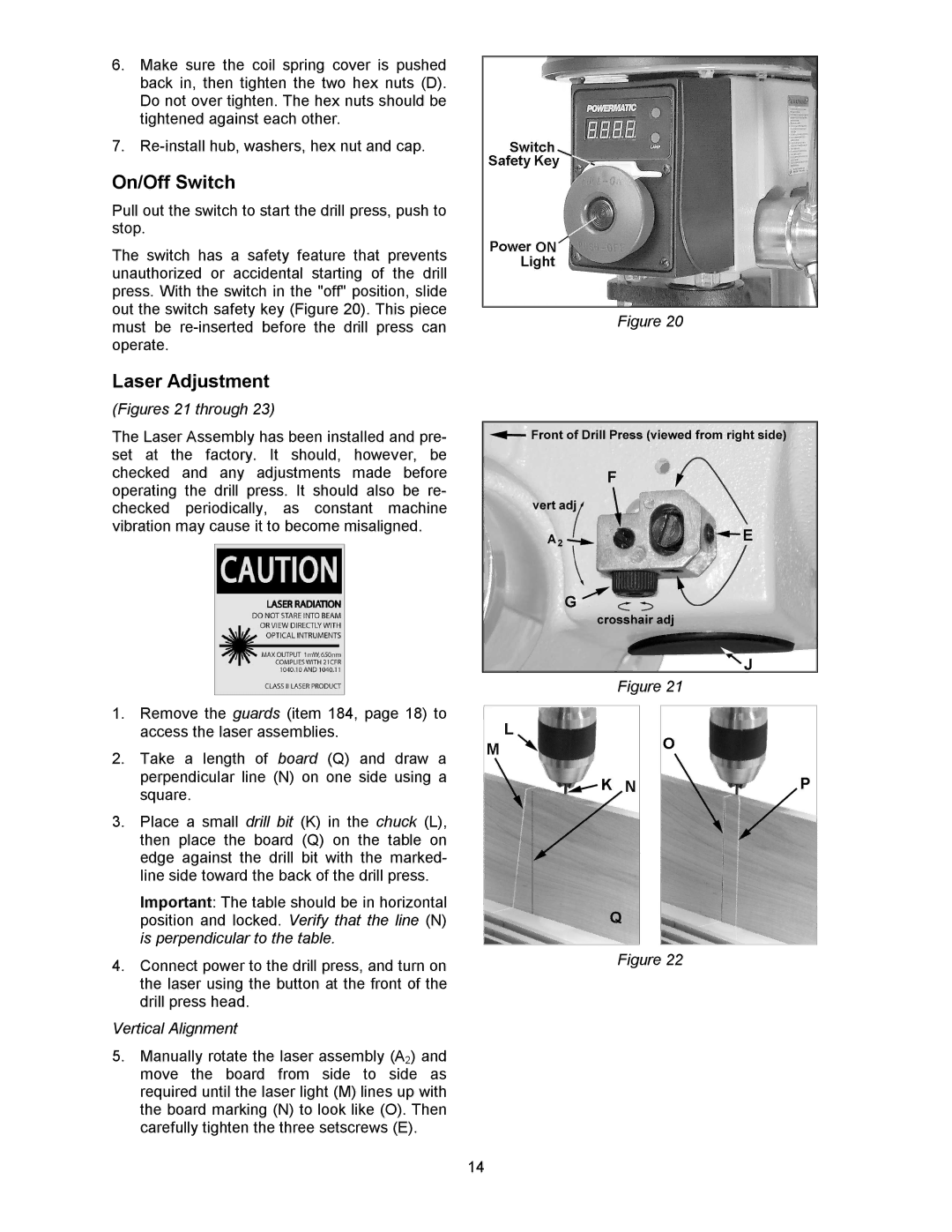

Laser Adjustment

(Figures 21 through 23)

The Laser Assembly has been installed and pre- set at the factory. It should, however, be checked and any adjustments made before operating the drill press. It should also be re- checked periodically, as constant machine vibration may cause it to become misaligned.

1.Remove the guards (item 184, page 18) to access the laser assemblies.

2.Take a length of board (Q) and draw a perpendicular line (N) on one side using a square.

3.Place a small drill bit (K) in the chuck (L), then place the board (Q) on the table on edge against the drill bit with the marked- line side toward the back of the drill press.

Important: The table should be in horizontal position and locked. Verify that the line (N) is perpendicular to the table.

4.Connect power to the drill press, and turn on the laser using the button at the front of the drill press head.

Vertical Alignment

5.Manually rotate the laser assembly (A2) and move the board from side to side as required until the laser light (M) lines up with the board marking (N) to look like (O). Then carefully tighten the three setscrews (E).

Figure 20

Figure 21

Figure 22

14