3.Slide the large handle onto the spindle of the table bracket (Figure 4), and tighten the set screw in the handle with a 3mm hex wrench. Crank the handle counterclockwise to lower the table bracket down the column.

4.Place the ring onto the column and slide it down over the top edge of the rack (see Figure 3). Tighten the set screw on the ring.

5.Screw the locking handle into the table bracket (Figure 4) and tighten the locking handle to secure the table bracket’s position on the column.

Head Assembly

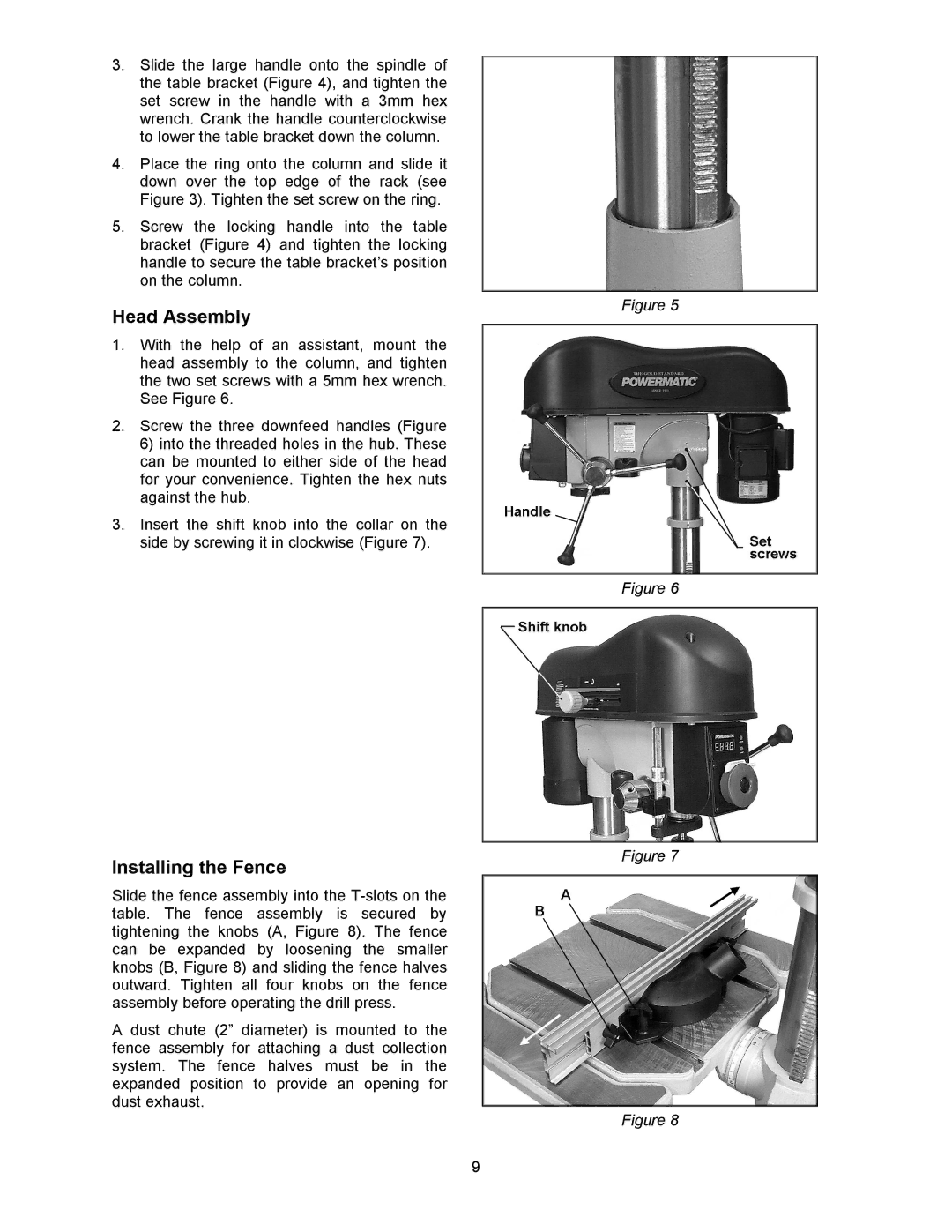

1.With the help of an assistant, mount the head assembly to the column, and tighten the two set screws with a 5mm hex wrench. See Figure 6.

2.Screw the three downfeed handles (Figure

6)into the threaded holes in the hub. These can be mounted to either side of the head for your convenience. Tighten the hex nuts against the hub.

3.Insert the shift knob into the collar on the side by screwing it in clockwise (Figure 7).

Installing the Fence

Slide the fence assembly into the

A dust chute (2” diameter) is mounted to the fence assembly for attaching a dust collection system. The fence halves must be in the expanded position to provide an opening for dust exhaust.

Figure 5

Figure 6

Figure 7

Figure 8

9