The clamping cylinders can also be adjusted laterally for better support of workpieces with differing widths. Simply loosen the locking handle (Figure 11) and slide the clamping cylinder to position.

Clamping Pressure

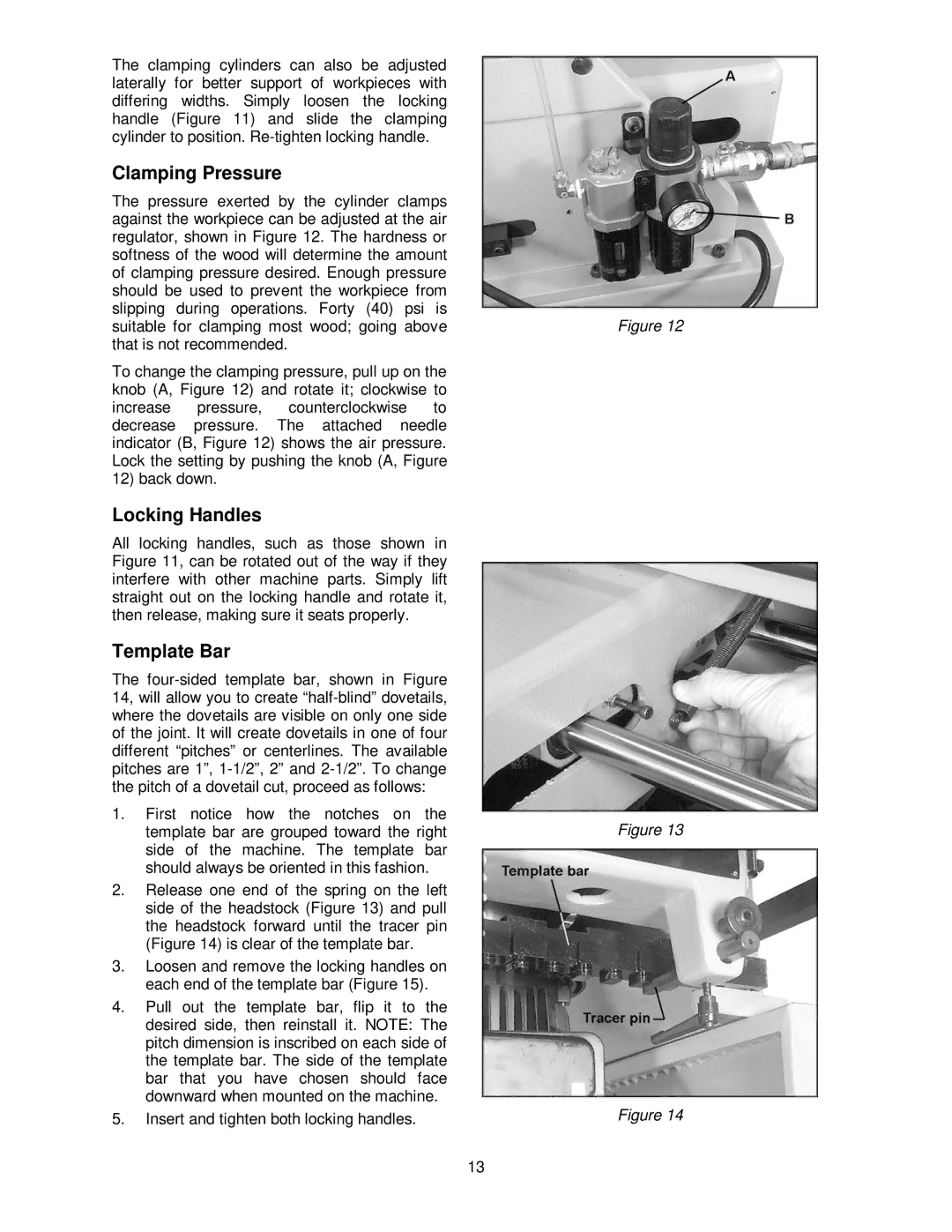

The pressure exerted by the cylinder clamps against the workpiece can be adjusted at the air regulator, shown in Figure 12. The hardness or softness of the wood will determine the amount of clamping pressure desired. Enough pressure should be used to prevent the workpiece from slipping during operations. Forty (40) psi is suitable for clamping most wood; going above that is not recommended.

To change the clamping pressure, pull up on the knob (A, Figure 12) and rotate it; clockwise to increase pressure, counterclockwise to decrease pressure. The attached needle indicator (B, Figure 12) shows the air pressure. Lock the setting by pushing the knob (A, Figure 12) back down.

Locking Handles

All locking handles, such as those shown in Figure 11, can be rotated out of the way if they interfere with other machine parts. Simply lift straight out on the locking handle and rotate it, then release, making sure it seats properly.

Template Bar

The

1.First notice how the notches on the template bar are grouped toward the right side of the machine. The template bar should always be oriented in this fashion.

2.Release one end of the spring on the left side of the headstock (Figure 13) and pull the headstock forward until the tracer pin (Figure 14) is clear of the template bar.

3.Loosen and remove the locking handles on each end of the template bar (Figure 15).

4.Pull out the template bar, flip it to the desired side, then reinstall it. NOTE: The pitch dimension is inscribed on each side of the template bar. The side of the template bar that you have chosen should face downward when mounted on the machine.

5.Insert and tighten both locking handles.

Figure 12

Figure 13

Figure 14

13