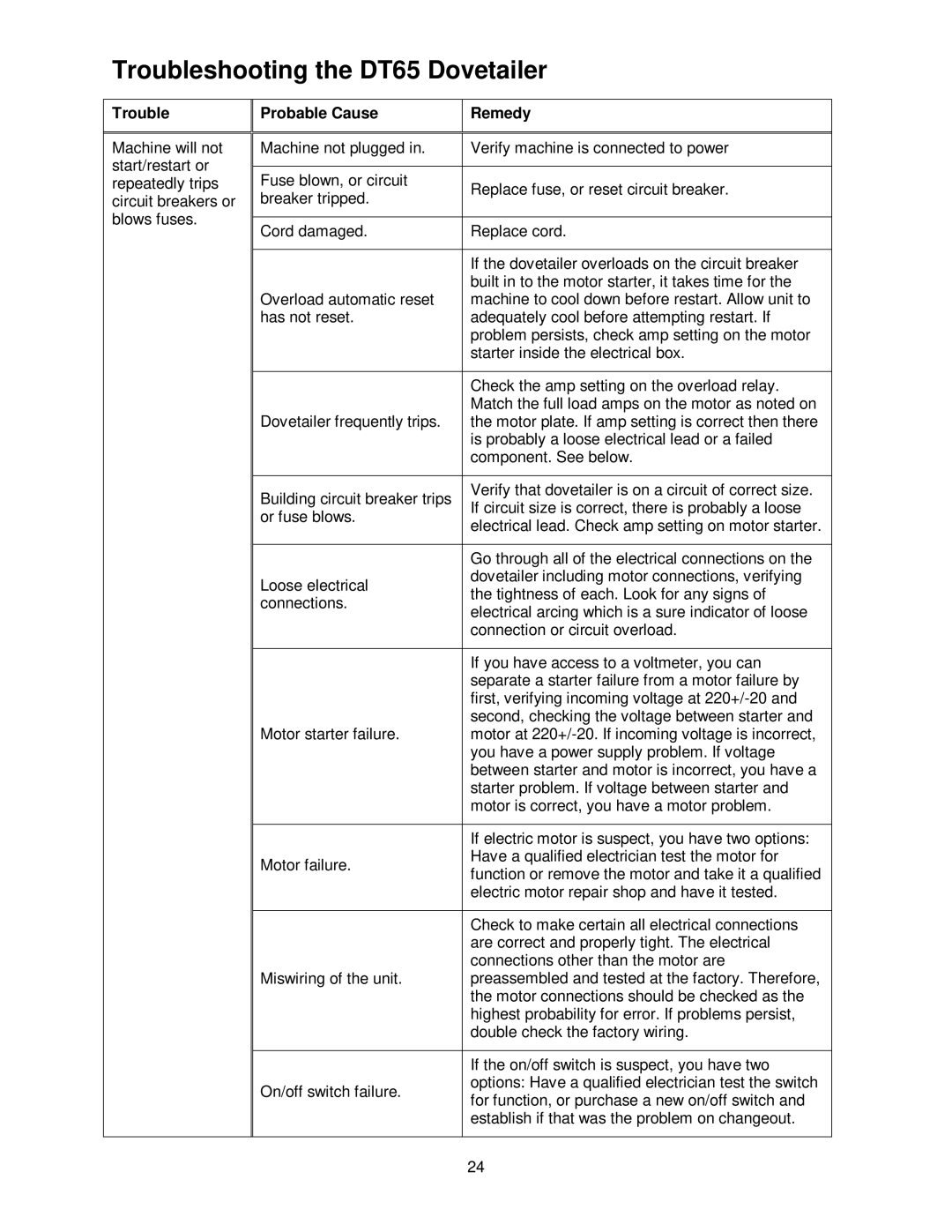

Troubleshooting the DT65 Dovetailer

Trouble

Machine will not start/restart or repeatedly trips circuit breakers or blows fuses.

Probable Cause | Remedy | |

|

| |

Machine not plugged in. | Verify machine is connected to power | |

|

| |

Fuse blown, or circuit | Replace fuse, or reset circuit breaker. | |

breaker tripped. | ||

| ||

|

| |

Cord damaged. | Replace cord. | |

|

| |

| If the dovetailer overloads on the circuit breaker | |

| built in to the motor starter, it takes time for the | |

Overload automatic reset | machine to cool down before restart. Allow unit to | |

has not reset. | adequately cool before attempting restart. If | |

| problem persists, check amp setting on the motor | |

| starter inside the electrical box. | |

|

| |

| Check the amp setting on the overload relay. | |

Dovetailer frequently trips. | Match the full load amps on the motor as noted on | |

the motor plate. If amp setting is correct then there | ||

| is probably a loose electrical lead or a failed | |

| component. See below. | |

|

| |

Building circuit breaker trips | Verify that dovetailer is on a circuit of correct size. | |

If circuit size is correct, there is probably a loose | ||

or fuse blows. | ||

electrical lead. Check amp setting on motor starter. | ||

| ||

|

| |

| Go through all of the electrical connections on the | |

Loose electrical | dovetailer including motor connections, verifying | |

the tightness of each. Look for any signs of | ||

connections. | ||

electrical arcing which is a sure indicator of loose | ||

| ||

| connection or circuit overload. | |

|

| |

| If you have access to a voltmeter, you can | |

| separate a starter failure from a motor failure by | |

| first, verifying incoming voltage at | |

Motor starter failure. | second, checking the voltage between starter and | |

motor at | ||

| you have a power supply problem. If voltage | |

| between starter and motor is incorrect, you have a | |

| starter problem. If voltage between starter and | |

| motor is correct, you have a motor problem. | |

|

| |

| If electric motor is suspect, you have two options: | |

Motor failure. | Have a qualified electrician test the motor for | |

function or remove the motor and take it a qualified | ||

| ||

| electric motor repair shop and have it tested. | |

|

| |

| Check to make certain all electrical connections | |

| are correct and properly tight. The electrical | |

| connections other than the motor are | |

Miswiring of the unit. | preassembled and tested at the factory. Therefore, | |

| the motor connections should be checked as the | |

| highest probability for error. If problems persist, | |

| double check the factory wiring. | |

|

| |

| If the on/off switch is suspect, you have two | |

On/off switch failure. | options: Have a qualified electrician test the switch | |

for function, or purchase a new on/off switch and | ||

| ||

| establish if that was the problem on changeout. | |

|

|

24