Operation

NOTE: The following are basic dovetailing procedures as they apply to this machine, and are not intended to be a full course of instruction in making dovetails.

Refer back to the terminology on page 7 if needed.

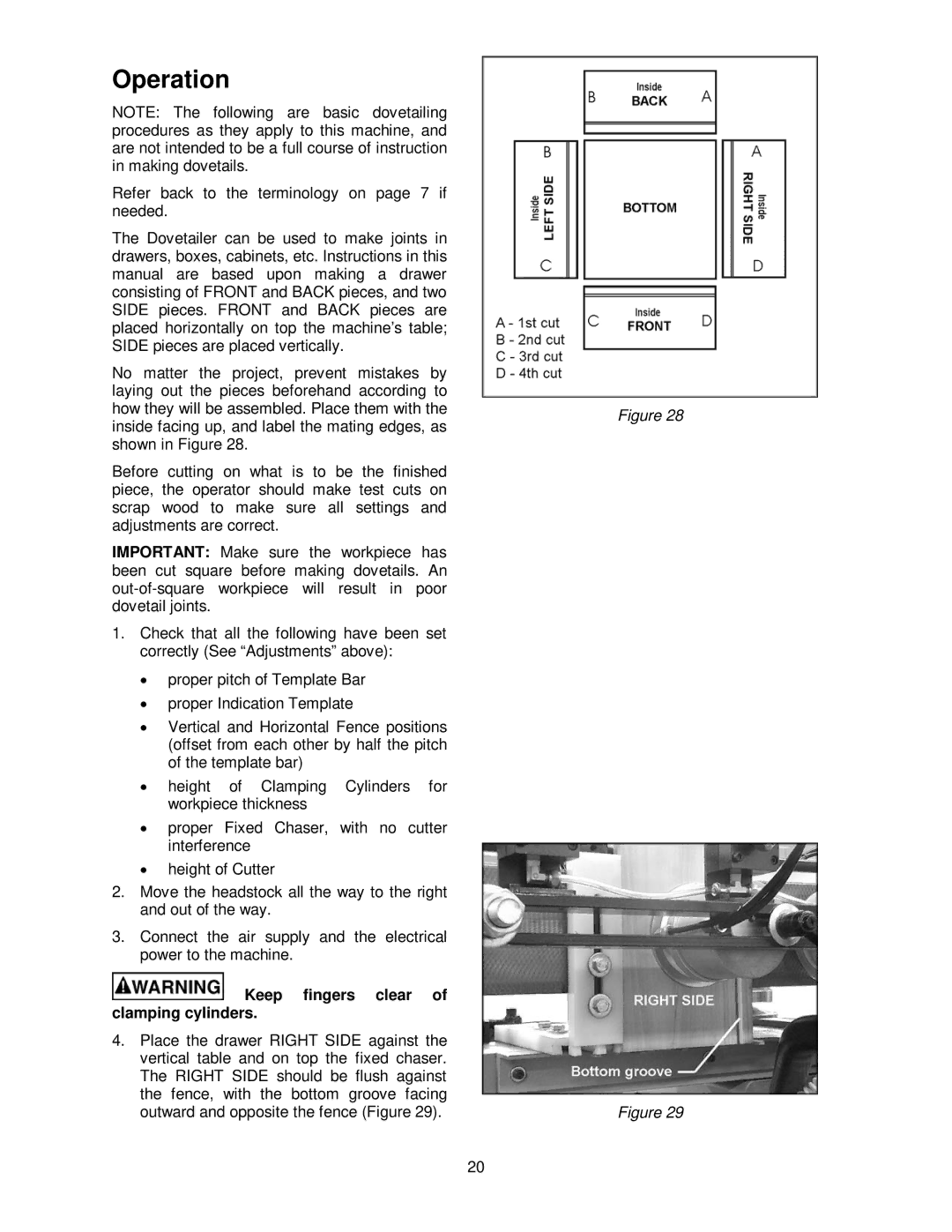

The Dovetailer can be used to make joints in drawers, boxes, cabinets, etc. Instructions in this manual are based upon making a drawer consisting of FRONT and BACK pieces, and two SIDE pieces. FRONT and BACK pieces are placed horizontally on top the machine’s table; SIDE pieces are placed vertically.

No matter the project, prevent mistakes by laying out the pieces beforehand according to how they will be assembled. Place them with the inside facing up, and label the mating edges, as shown in Figure 28.

Before cutting on what is to be the finished piece, the operator should make test cuts on scrap wood to make sure all settings and adjustments are correct.

IMPORTANT: Make sure the workpiece has been cut square before making dovetails. An

1.Check that all the following have been set correctly (See “Adjustments” above):

•proper pitch of Template Bar

•proper Indication Template

•Vertical and Horizontal Fence positions (offset from each other by half the pitch of the template bar)

•height of Clamping Cylinders for workpiece thickness

•proper Fixed Chaser, with no cutter interference

•height of Cutter

2.Move the headstock all the way to the right and out of the way.

3.Connect the air supply and the electrical power to the machine.

Keep fingers clear of clamping cylinders.

Keep fingers clear of clamping cylinders.

4.Place the drawer RIGHT SIDE against the vertical table and on top the fixed chaser. The RIGHT SIDE should be flush against the fence, with the bottom groove facing outward and opposite the fence (Figure 29).

Figure 28

Figure 29

20