BEFORE USING CANNER FOR THE FIRST TIME

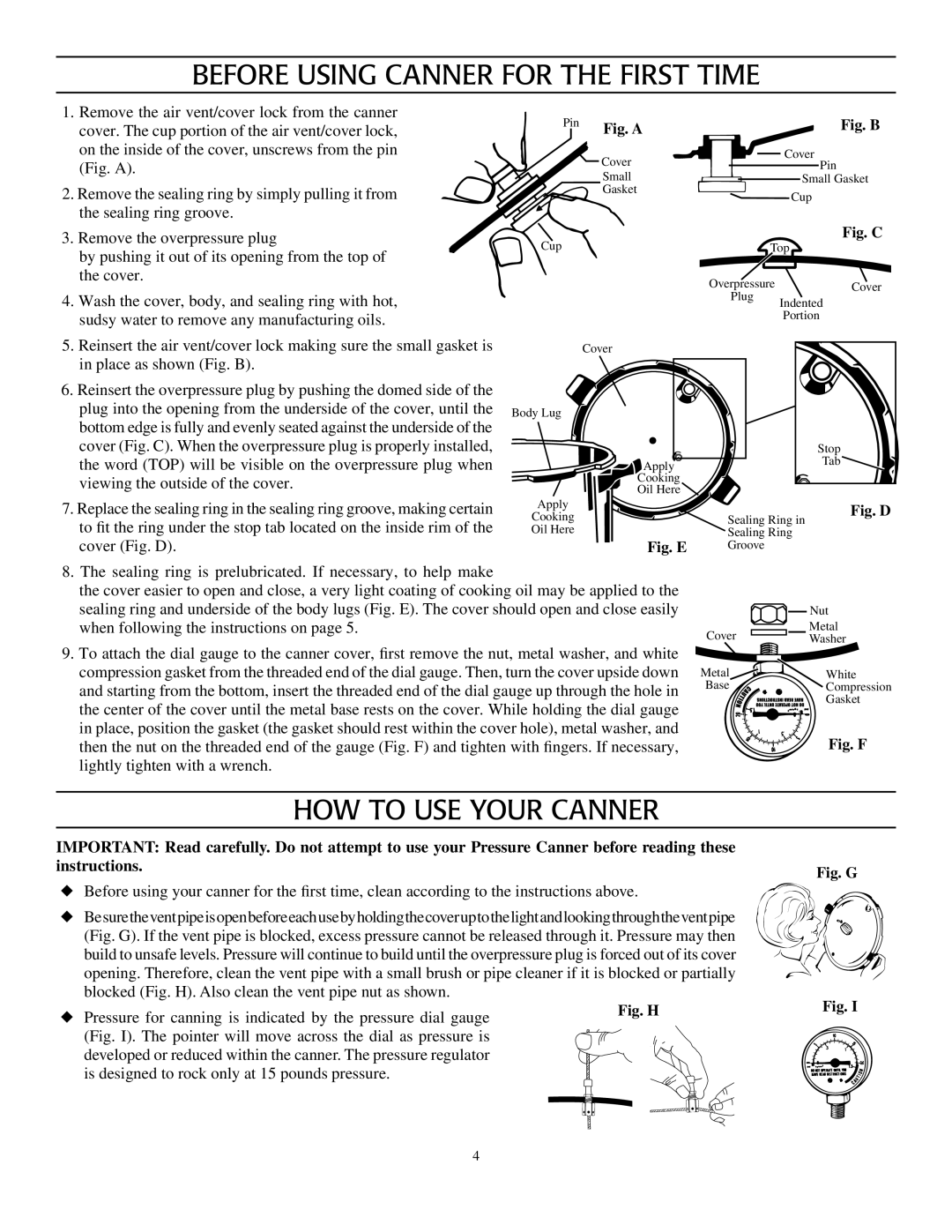

1. Remove the air vent/cover lock from the canner | Pin |

|

| Fig. A |

|

|

|

|

|

|

|

|

| Fig. B | |||

cover. The cup portion of the air vent/cover lock, |

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

on the inside of the cover, unscrews from the pin |

|

|

|

| Cover |

|

|

|

|

| Cover |

| |||||

|

|

|

|

|

|

|

|

|

| ||||||||

(Fig. A). |

|

|

|

|

|

|

|

|

|

|

|

| Pin |

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

| Small |

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

| Small Gasket | |||||

|

|

|

|

|

|

|

|

|

|

|

| ||||||

2. Remove the sealing ring by simply pulling it from |

|

|

|

| Gasket |

|

|

|

|

| Cup |

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

the sealing ring groove. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3. Remove the overpressure plug | Cup |

|

|

|

|

|

|

|

|

| Top | Fig. C | |||||

|

|

|

|

|

|

|

|

|

| ||||||||

by pushing it out of its opening from the top of |

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

the cover. |

|

|

|

|

|

|

| Overpressure |

|

|

|

| Cover | ||||

|

|

|

|

|

|

|

|

|

|

|

| ||||||

4. Wash the cover, body, and sealing ring with hot, |

|

|

|

|

|

|

|

| Plug | Indented |

| ||||||

sudsy water to remove any manufacturing oils. |

|

|

|

|

|

|

|

|

|

|

|

| Portion |

| |||

5. Reinsert the air vent/cover lock making sure the small gasket is |

|

| Cover |

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

| ||||||

in place as shown (Fig. B). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

6. Reinsert the overpressure plug by pushing the domed side of the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

plug into the opening from the underside of the cover, until the | Body Lug |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

bottom edge is fully and evenly seated against the underside of the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

cover (Fig. C). When the overpressure plug is properly installed, |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Stop |

| |

the word (TOP) will be visible on the overpressure plug when |

|

|

|

|

| Apply |

|

|

|

|

|

|

|

|

| Tab |

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

viewing the outside of the cover. |

|

|

|

|

| Cooking |

|

|

|

|

|

|

|

|

|

| |

Apply |

|

|

| Oil Here |

|

|

|

|

|

|

|

|

|

| |||

7. Replace the sealing ring in the sealing ring groove, making certain |

|

|

|

|

|

|

|

|

|

|

|

| Fig. D | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

Cooking |

|

|

|

|

| Sealing Ring in | |||||||||||

to fit the ring under the stop tab located on the inside rim of the |

|

|

|

|

|

| |||||||||||

Oil Here |

|

|

|

|

| Sealing Ring |

| ||||||||||

cover (Fig. D). |

|

|

|

|

| Fig. E | Groove |

|

|

|

|

| |||||

8.The sealing ring is prelubricated. If necessary, to help make

the cover easier to open and close, a very light coating of cooking oil may be applied to the sealing ring and underside of the body lugs (Fig. E). The cover should open and close easily when following the instructions on page 5.

9.To attach the dial gauge to the canner cover, first remove the nut, metal washer, and white compression gasket from the threaded end of the dial gauge. Then, turn the cover upside down and starting from the bottom, insert the threaded end of the dial gauge up through the hole in the center of the cover until the metal base rests on the cover. While holding the dial gauge in place, position the gasket (the gasket should rest within the cover hole), metal washer, and then the nut on the threaded end of the gauge (Fig. F) and tighten with fingers. If necessary, lightly tighten with a wrench.

Nut

Metal

Cover ![]()

![]() Washer

Washer

Metal | White |

Base | Compression |

| Gasket |

Fig. F

How to Use YOUR CANNER

IMPORTANT: Read carefully. Do not attempt to use your Pressure Canner before reading these instructions.

Before using your canner for the first time, clean according to the instructions above.

Besuretheventpipeisopenbeforeeachusebyholdingthecoveruptothelightandlookingthroughtheventpipe (Fig. G). If the vent pipe is blocked, excess pressure cannot be released through it. Pressure may then build to unsafe levels. Pressure will continue to build until the overpressure plug is forced out of its cover opening. Therefore, clean the vent pipe with a small brush or pipe cleaner if it is blocked or partially blocked (Fig. H). Also clean the vent pipe nut as shown.

Pressure for canning is indicated by the pressure dial gauge | Fig. H |

| |

(Fig. I). The pointer will move across the dial as pressure is |

|

developed or reduced within the canner. The pressure regulator |

|

is designed to rock only at 15 pounds pressure. |

|

Fig. G

Fig. I

4