Use the canner on a level burner and range only. Use on a tilted burner or range may interfere with the operation of the pressure regulator. Caution: Do not use pressure canner on an outdoor LP gas burner or gas range over 12,000 BTU’s.

The canner has been designed so the cover will go on in only one position and rotate in only the directions indicated for closing and opening. Press down on the cover handles to compress the sealing ring and make the cover easier to close. The cover has the words

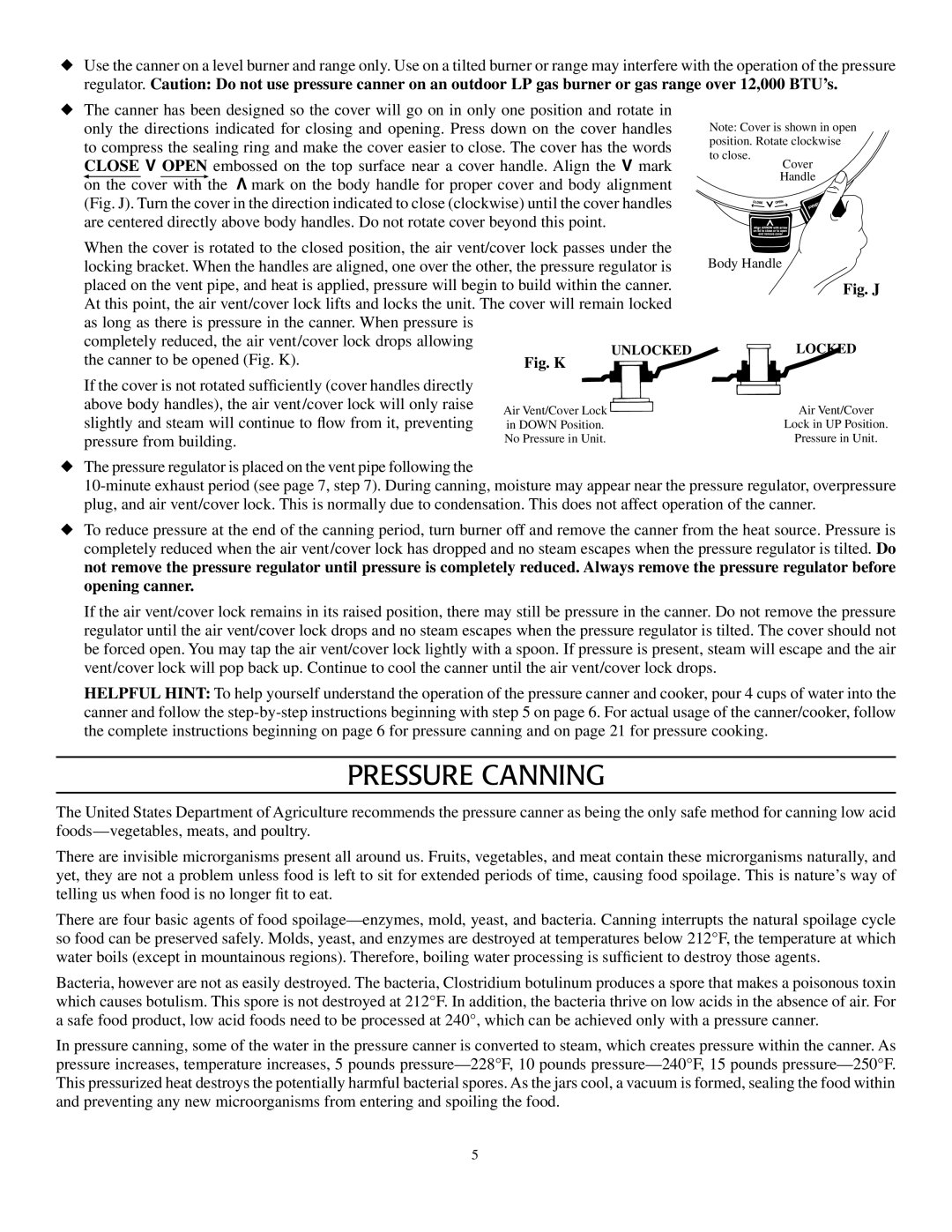

CLOSE V OPEN embossed on the top surface near a cover handle. Align the V mark on the cover with the V mark on the body handle for proper cover and body alignment (Fig. J). Turn the cover in the direction indicated to close (clockwise) until the cover handles are centered directly above body handles. Do not rotate cover beyond this point.

When the cover is rotated to the closed position, the air vent/cover lock passes under the locking bracket. When the handles are aligned, one over the other, the pressure regulator is placed on the vent pipe, and heat is applied, pressure will begin to build within the canner. At this point, the air vent/cover lock lifts and locks the unit. The cover will remain locked as long as there is pressure in the canner. When pressure is

completely reduced, the air vent/cover lock drops allowingUNLOCKED the canner to be opened (Fig. K).

If the cover is not rotated sufficiently (cover handles directly |

| |

above body handles), the air vent/cover lock will only raise | Air Vent/Cover Lock | |

slightly and steam will continue to flow from it, preventing | ||

in DOWN Position. | ||

pressure from building. | No Pressure in Unit. |

Note: Cover is shown in open position. Rotate clockwise

to close.

Cover

Handle

Body Handle

Fig. J

LOCKED

Air Vent/Cover

Lock in UP Position.

Pressure in Unit.

The pressure regulator is placed on the vent pipe following the

To reduce pressure at the end of the canning period, turn burner off and remove the canner from the heat source. Pressure is completely reduced when the air vent/cover lock has dropped and no steam escapes when the pressure regulator is tilted. Do not remove the pressure regulator until pressure is completely reduced. Always remove the pressure regulator before opening canner.

If the air vent/cover lock remains in its raised position, there may still be pressure in the canner. Do not remove the pressure regulator until the air vent/cover lock drops and no steam escapes when the pressure regulator is tilted. The cover should not be forced open. You may tap the air vent/cover lock lightly with a spoon. If pressure is present, steam will escape and the air vent/cover lock will pop back up. Continue to cool the canner until the air vent/cover lock drops.

HELPFUL HINT: To help yourself understand the operation of the pressure canner and cooker, pour 4 cups of water into the canner and follow the

PRESSURE CANNING

The United States Department of Agriculture recommends the pressure canner as being the only safe method for canning low acid

There are invisible microrganisms present all around us. Fruits, vegetables, and meat contain these microrganisms naturally, and yet, they are not a problem unless food is left to sit for extended periods of time, causing food spoilage. This is nature’s way of telling us when food is no longer fit to eat.

There are four basic agents of food

Bacteria, however are not as easily destroyed. The bacteria, Clostridium botulinum produces a spore that makes a poisonous toxin which causes botulism. This spore is not destroyed at 212°F. In addition, the bacteria thrive on low acids in the absence of air. For a safe food product, low acid foods need to be processed at 240°, which can be achieved only with a pressure canner.

In pressure canning, some of the water in the pressure canner is converted to steam, which creates pressure within the canner. As pressure increases, temperature increases, 5 pounds

5