The header is printed in text mode and the rest part of this slip is printed in page mode. If FEED button is pressed at this moment, a font table will be printed in text mode again. To exit the test printing, please turn the printer off and on again.

C. SPECIAL ADJUSTMENTS

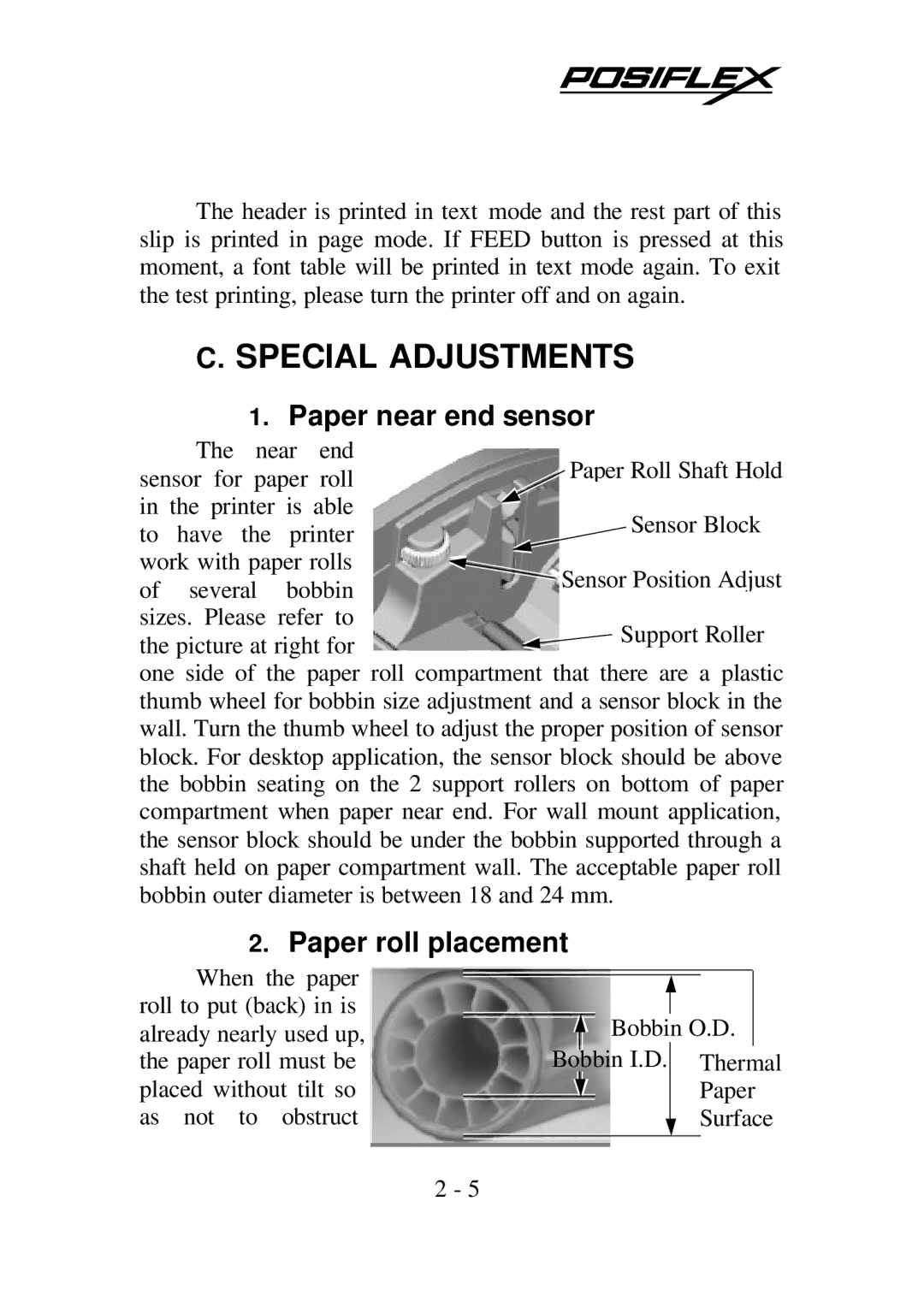

1.Paper near end sensor

The near end

sensor for paper roll in the printer is able

to have the printer work with paper rolls

of several bobbin sizes. Please refer to

the picture at right for

one side of the paper roll compartment that there are a plastic thumb wheel for bobbin size adjustment and a sensor block in the wall. Turn the thumb wheel to adjust the proper position of sensor block. For desktop application, the sensor block should be above the bobbin seating on the 2 support rollers on bottom of paper compartment when paper near end. For wall mount application, the sensor block should be under the bobbin supported through a shaft held on paper compartment wall. The acceptable paper roll bobbin outer diameter is between 18 and 24 mm.

2.Paper roll placement

When the paper roll to put (back) in is already nearly used up, the paper roll must be placed without tilt so as not to obstruct

Bobbin O.D. | |

Bobbin I.D. | Thermal |

| Paper |

| Surface |

2 - 5