R

4300 ACT Wood Stove Series

FLUE SYSTEMS | MASONRY CHIMNEY (Cont’d) |

There are two separate and different parts to a flue system: the chimney connector and the chimney itself.

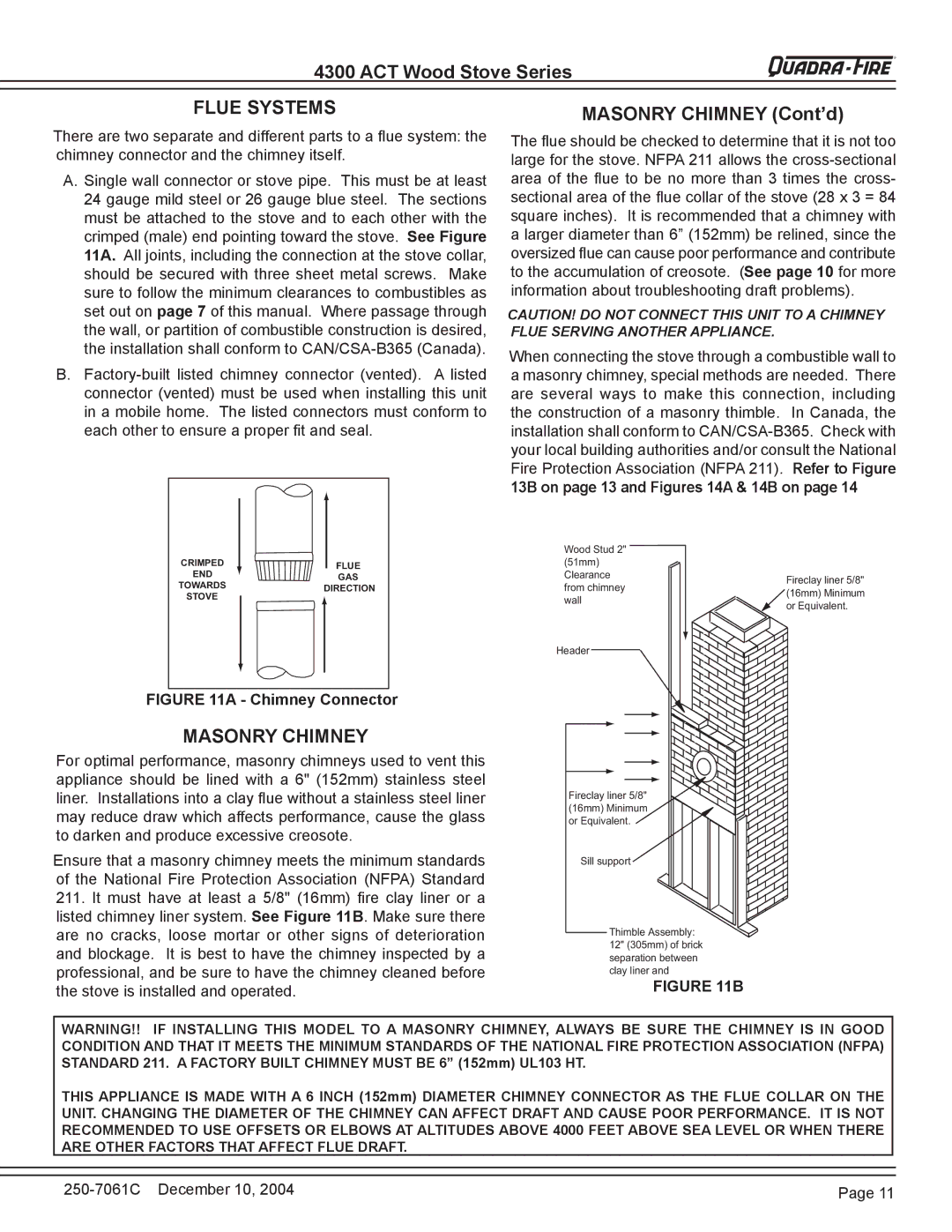

A. Single wall connector or stove pipe. This must be at least 24 gauge mild steel or 26 gauge blue steel. The sections must be attached to the stove and to each other with the crimped (male) end pointing toward the stove. See Figure 11A. All joints, including the connection at the stove collar, should be secured with three sheet metal screws. Make sure to follow the minimum clearances to combustibles as set out on page 7 of this manual. Where passage through the wall, or partition of combustible construction is desired, the installation shall conform to

B.

CRIMPED | FLUE |

END | GAS |

TOWARDS | DIRECTION |

STOVE |

|

The flue should be checked to determine that it is not too large for the stove. NFPA 211 allows the

CAUTION! DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE.

When connecting the stove through a combustible wall to a masonry chimney, special methods are needed. There are several ways to make this connection, including the construction of a masonry thimble. In Canada, the installation shall conform to

Wood Stud 2" |

| |

(51mm) |

| |

Clearance | Fireclay liner 5/8" | |

from chimney | ||

(16mm) Minimum | ||

wall | ||

or Equivalent. | ||

| ||

Header |

|

FIGURE 11A - Chimney Connector

MASONRY CHIMNEY

For optimal performance, masonry chimneys used to vent this appliance should be lined with a 6" (152mm) stainless steel liner. Installations into a clay flue without a stainless steel liner may reduce draw which affects performance, cause the glass to darken and produce excessive creosote.

Ensure that a masonry chimney meets the minimum standards of the National Fire Protection Association (NFPA) Standard

211.It must have at least a 5/8" (16mm) fire clay liner or a listed chimney liner system. See Figure 11B. Make sure there are no cracks, loose mortar or other signs of deterioration and blockage. It is best to have the chimney inspected by a professional, and be sure to have the chimney cleaned before the stove is installed and operated.

Fireclay liner 5/8" (16mm) Minimum or Equivalent.

Sill support

Thimble Assembly: 12" (305mm) of brick separation between clay liner and

combustiblesFIGURE. 11B

WARNING!! IF INSTALLING THIS MODEL TO A MASONRY CHIMNEY, ALWAYS BE SURE THE CHIMNEY IS IN GOOD CONDITION AND THAT IT MEETS THE MINIMUM STANDARDS OF THE NATIONAL FIRE PROTECTION ASSOCIATION (NFPA) STANDARD 211. A FACTORY BUILT CHIMNEY MUST BE 6” (152mm) UL103 HT.

THIS APPLIANCE IS MADE WITH A 6 INCH (152mm) DIAMETER CHIMNEY CONNECTOR AS THE FLUE COLLAR ON THE UNIT. CHANGING THE DIAMETER OF THE CHIMNEY CAN AFFECT DRAFT AND CAUSE POOR PERFORMANCE. IT IS NOT RECOMMENDED TO USE OFFSETS OR ELBOWS AT ALTITUDES ABOVE 4000 FEET ABOVE SEA LEVEL OR WHEN THERE ARE OTHER FACTORS THAT AFFECT FLUE DRAFT.

Page 11 |