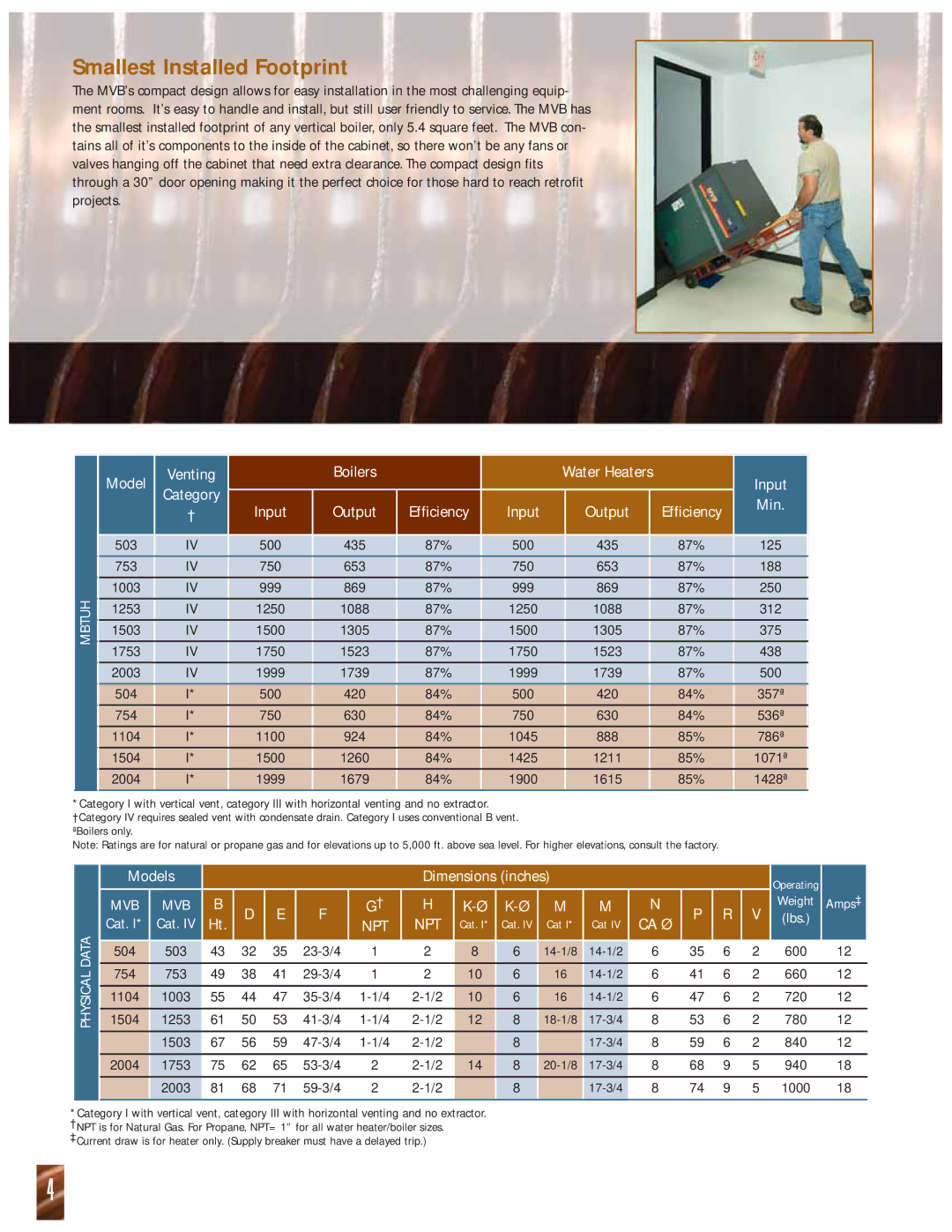

503 thru 2003, 504 thru 2004 specifications

Raypak, a well-known manufacturer in the HVAC and pool heating industry, has been at the forefront of innovation with their models 503 through 2003 and 504 through 2004. These models are recognized for their dependability, efficiency, and advanced features that cater to both residential and commercial applications.One of the primary characteristics of the Raypak models 503 and 504 is their robust construction. Built with durability in mind, these heaters use high-quality materials that withstand varying weather conditions, ensuring longevity and reduced maintenance costs. The exterior casing is designed to resist corrosion, a common issue in humid environments, thereby enhancing the unit's lifespan.

Energy efficiency is another standout feature of the Raypak 503 and 504 models. These units integrate advanced heating technologies that utilize less energy while providing ample heating power. The proprietary heat exchanger design maximizes thermal transfer, ensuring that more of the energy consumed is effectively used for heating purposes. This not only contributes to lower utility bills but also aligns with growing environmental concerns regarding energy consumption.

In terms of technology, the Raypak models incorporate user-friendly digital controls that simplify the operation of the heater. These controls allow users to set precise temperatures and monitor system performance easily. Additionally, the built-in diagnostics feature alerts users to any issues, facilitating prompt maintenance and reducing downtime.

The compact design of these models is another benefit that does not go unnoticed. They can be installed in tight spaces, making them ideal for residential properties with limited room for large heating units. This flexibility in installation allows homeowners and contractors to optimize available space without sacrificing heating performance.

Moreover, both the 503 and 504 models come with a range of safety features. These include automatic water temperature limit controls and built-in freeze protection, which are essential for preventing damage during cold weather.

In summary, Raypak's 503 from 2003 and 504 from 2004 models showcase a blend of durability, energy efficiency, advanced technologies, and user-friendly features. They represent a commitment to providing high-quality heating solutions that meet the demands of modern consumers and businesses alike. With a focus on reliability and performance, Raypak continues to set benchmarks in the heating industry.