cable in slot in cover (Fig. 27). Shield must be fully seated to

minimize radiation of modulated carrier.

Figure 27. Disconnect Co-Ax Shield First to Replace Cable.

Resolder Center Lead First on Installation.

Do Not Overheat Foil in Board.

LED indicator Replacement

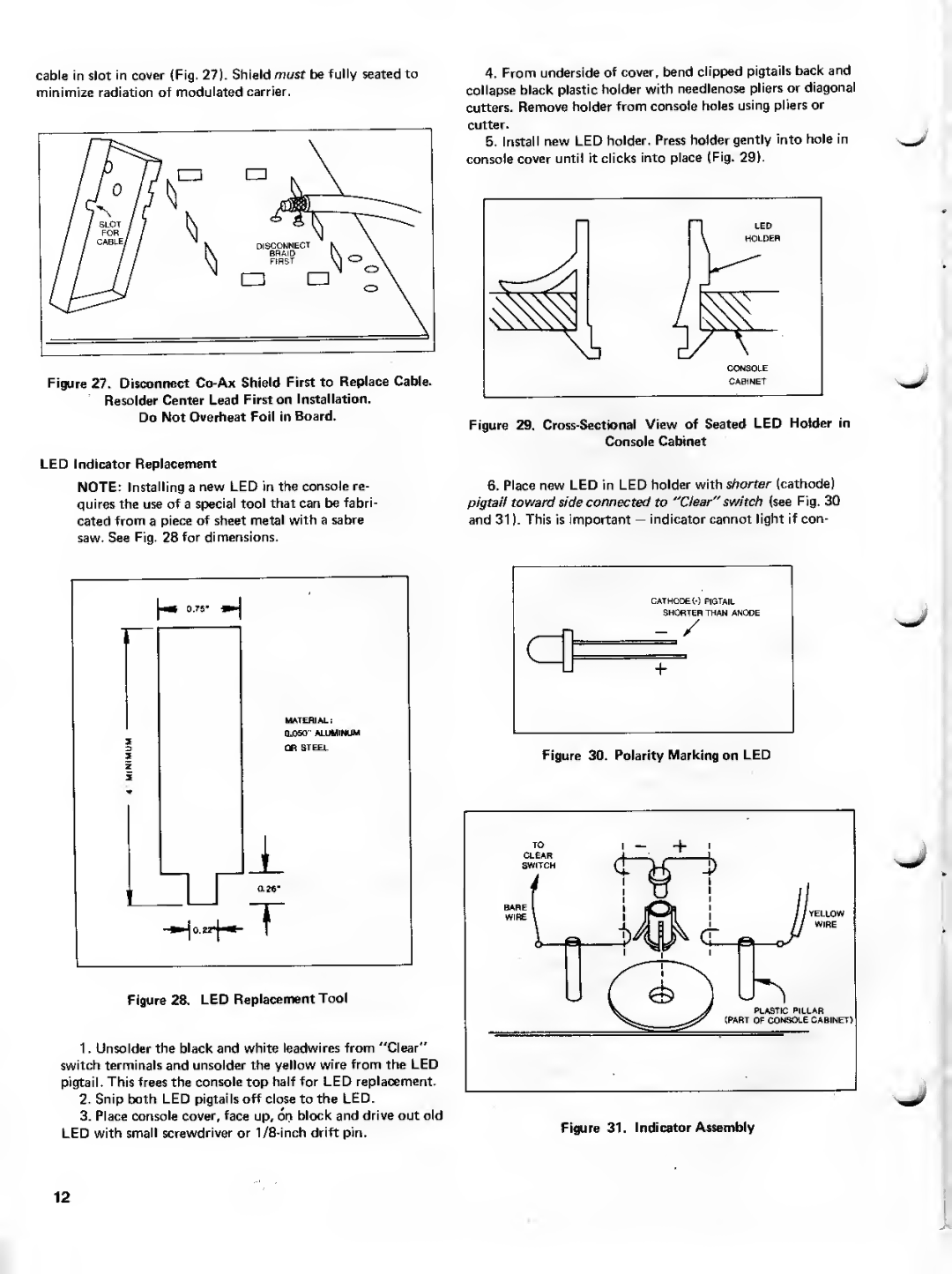

NOTE: Installing a new LED in the console re-

quires the use of a special tool that can be fabri-

cated from a piece of sheet metal with a sabre

saw. See Fig. 28 for dimensions.

*m 5.75- M

I

MATERIAL:

0.050 ALUMINUM

2

OOR STEEL

3 z

2

I

0.26"

Figure 28. LED Replacement Tool

1Unsolder the black and white leadwires from "Clear"

switch terminals and unsolder the yellow wire from the LED

pigtail. This frees the console top half for LED replacement.

2.Snip both LED pigtails off close to the LED.

3.Place console cover, face up, on block and drive out old

LED with small screwdriver or

4.From underside of cover, bend clipped pigtails back and collapse black plastic holder with needlenose pliers or diagonal cutters. Remove holder from console holes using pliers or

cutter.

5. Install new LED holder. Press holder gently into hole in

console cover until it clicks into place (Fig. 29).

Figure 29. Cross-Sectional View of Seated LED Holder in

Console Cabinet

6.Place new LED in LED holder with shorter (cathode)

pigtail toward side connected to "Clear" switch (see Fig. 30 and 31 ). This is important — indicator cannot light if con-

CATHODE

SHORTER THAN ANODE

d

+

Figure 30. Polarity Marking on LED

f¥ T>

/ YELLOW

>WIRE<r_

* n

PLASTIC PILLAR

(PART OF CONSOLE CABINET)

Figure 31. Indicator Assembly

sJ

*

J

j

^

,>

12