Selecting Power Fasteners and Power loads

FASTENING INTO CONCRETE

The proper power fastener length can be determined by adding the thickness of the material to be fastened and the amount of fastener that will actually penetrate the concrete. The concrete must be three times as thick as the intended fastener penetration. In most cases, pen- etration should be approximately 1" to 1 1/4" into the base concrete material.

Wood or

FASTENING INTO STEEL

The proper fastener length can be determined by adding the thickness of the material to be fastened and the thickness of the steel. The point of the power fastener must go completely through the steel.

POWER LOADS AND POWER

INDICATOR SETTING

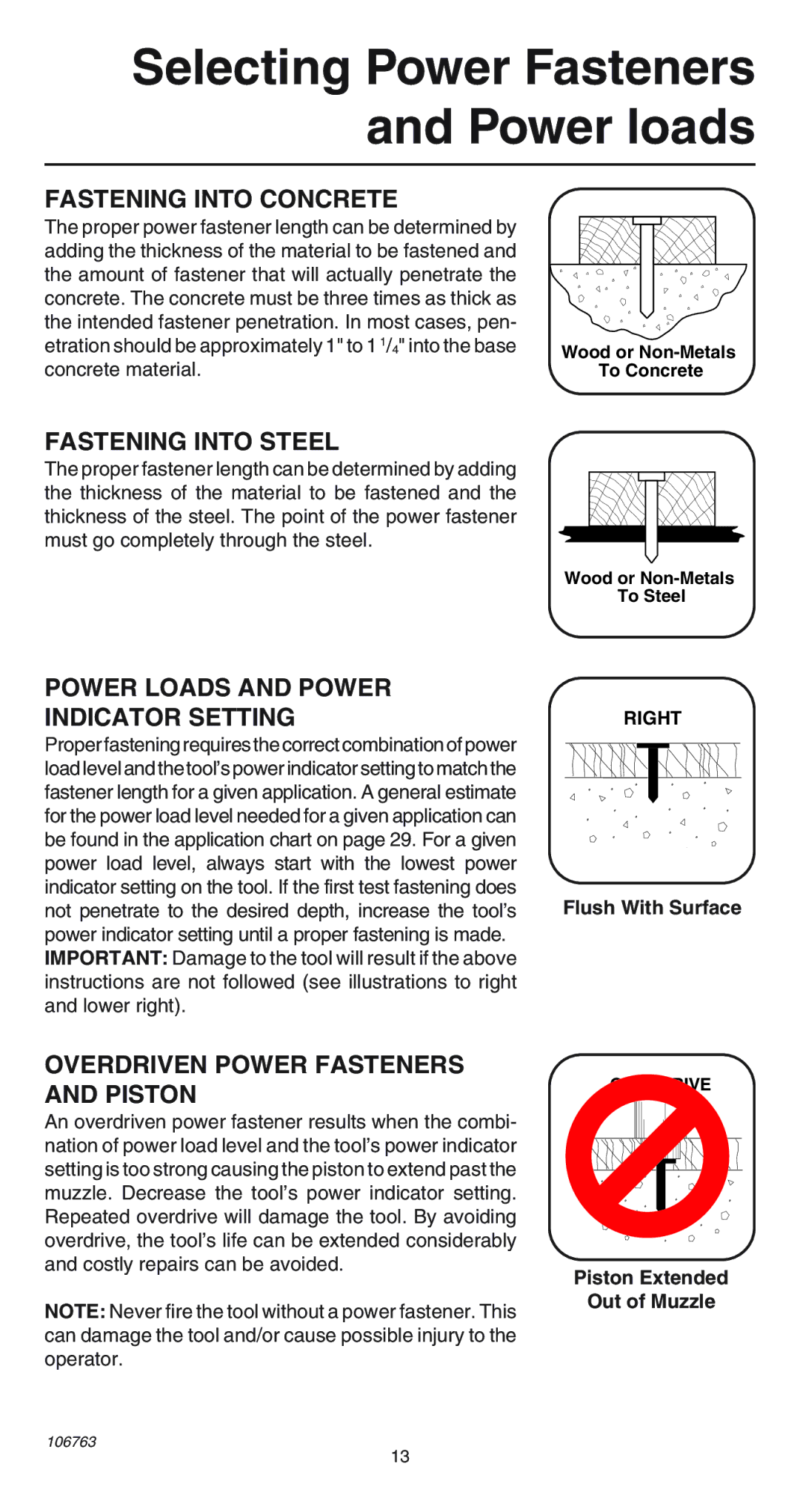

Proper fastening requires the correct combination of power load level and the tool’s power indicator setting to match the fastener length for a given application. A general estimate for the power load level needed for a given application can be found in the application chart on page 29. For a given power load level, always start with the lowest power indicator setting on the tool. If the first test fastening does not penetrate to the desired depth, increase the tool’s power indicator setting until a proper fastening is made.

IMPORTANT: Damage to the tool will result if the above instructions are not followed (see illustrations to right and lower right).

OVERDRIVEN POWER FASTENERS AND PISTON

An overdriven power fastener results when the combi- nation of power load level and the tool’s power indicator setting is too strong causing the piston to extend past the muzzle. Decrease the tool’s power indicator setting. Repeated overdrive will damage the tool. By avoiding overdrive, the tool’s life can be extended considerably and costly repairs can be avoided.

NOTE: Never fire the tool without a power fastener. This can damage the tool and/or cause possible injury to the operator.

106763

Wood or

RIGHT

Flush With Surface

OVERDRIVE

G 018

Piston Extended

Out of Muzzle

13