MAINTENANCE

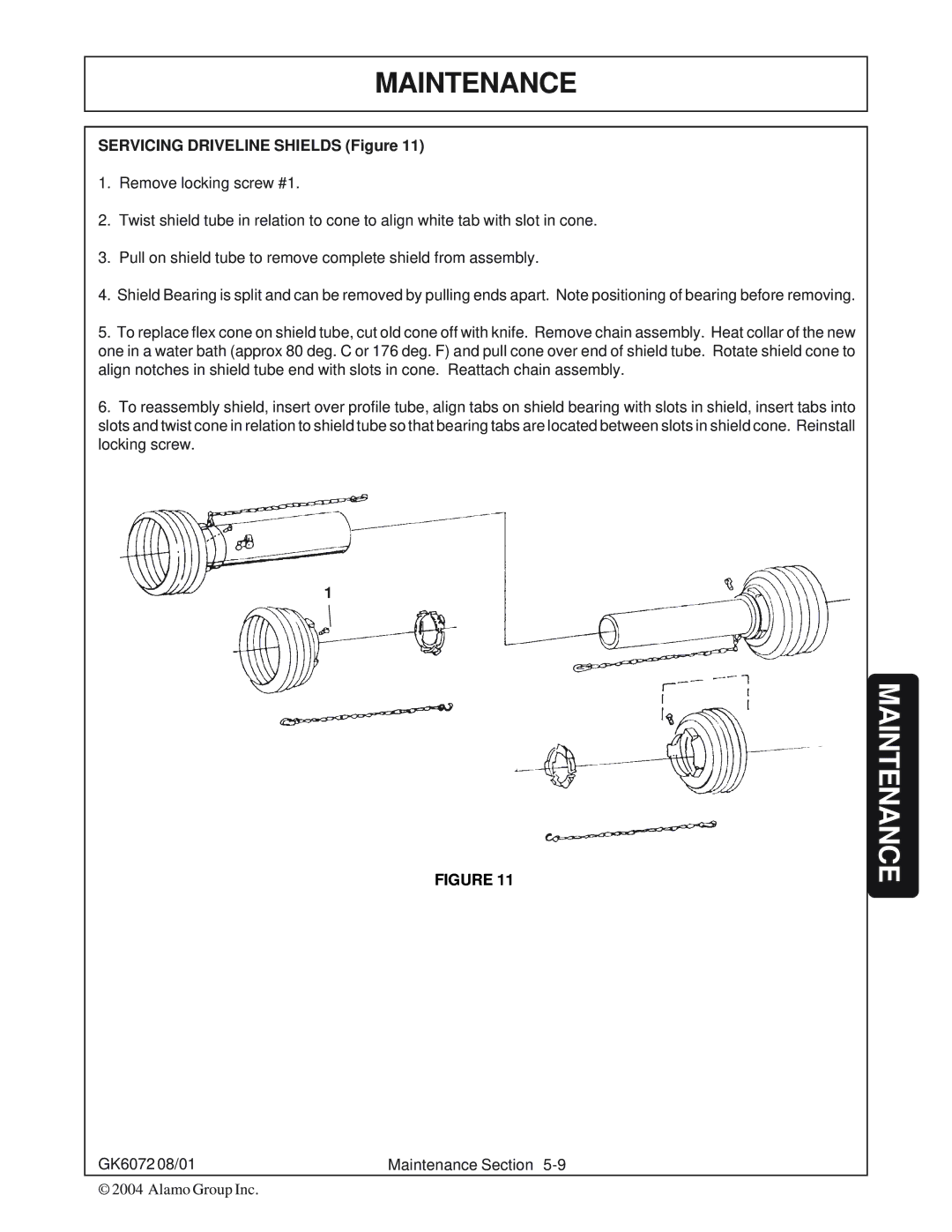

SERVICING DRIVELINE SHIELDS (Figure 11)

1.Remove locking screw #1.

2.Twist shield tube in relation to cone to align white tab with slot in cone.

3.Pull on shield tube to remove complete shield from assembly.

4.Shield Bearing is split and can be removed by pulling ends apart. Note positioning of bearing before removing.

5.To replace flex cone on shield tube, cut old cone off with knife. Remove chain assembly. Heat collar of the new one in a water bath (approx 80 deg. C or 176 deg. F) and pull cone over end of shield tube. Rotate shield cone to align notches in shield tube end with slots in cone. Reattach chain assembly.

6.To reassembly shield, insert over profile tube, align tabs on shield bearing with slots in shield, insert tabs into slots and twist cone in relation to shield tube so that bearing tabs are located between slots in shield cone. Reinstall locking screw.

1

FIGURE 11

GK6072 08/01 | Maintenance Section |

© 2004 Alamo Group Inc.