MAINTENANCE

BLADE SERVICING

Inspect blades before each use to determine that they are properly installed and in good condition. Replace any blade that is bent, excessively nicked, worn, or has any other damage. Small nicks can be ground out when sharpening.

Use only original equipment blades on this cutter. They are made of special

BLADE SHARPENING

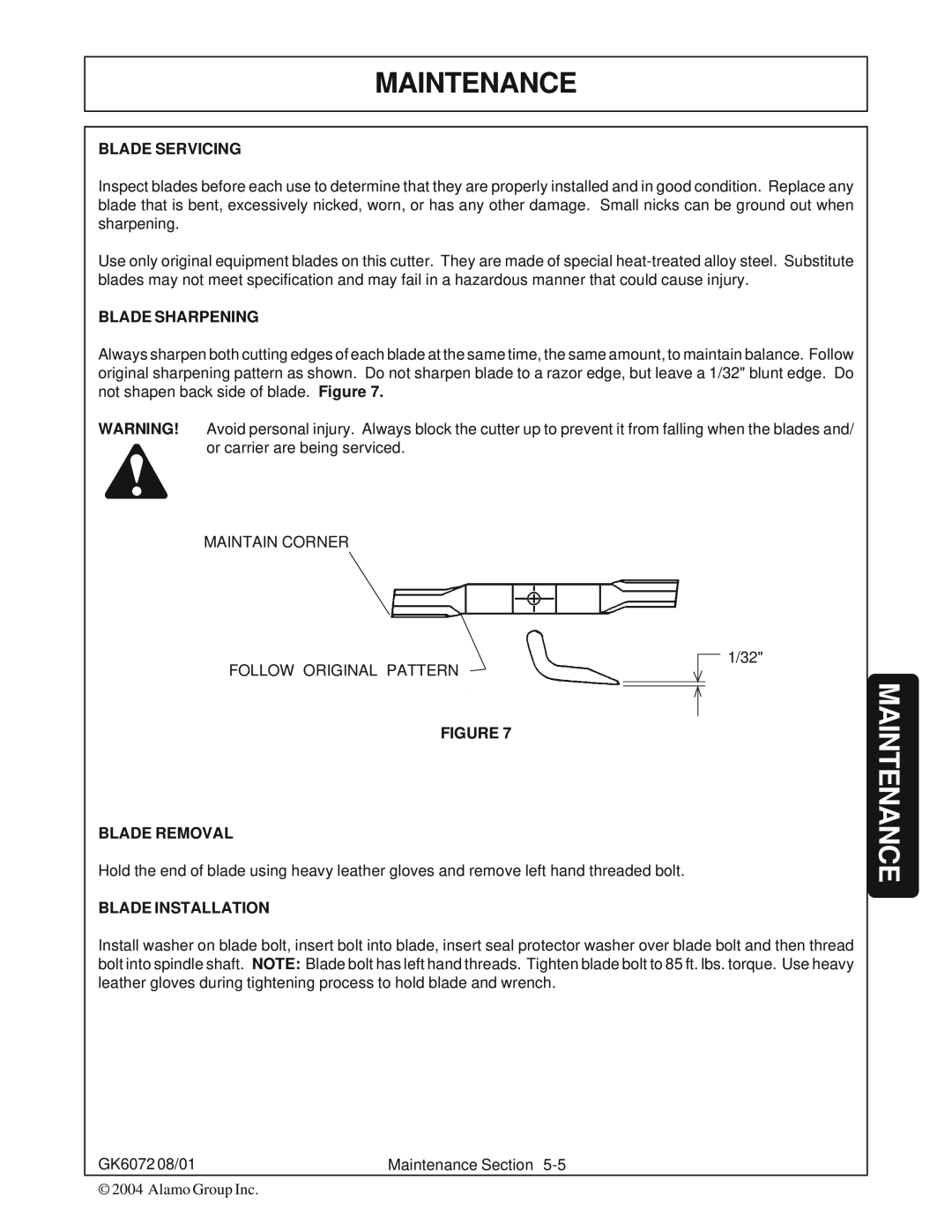

Always sharpen both cutting edges of each blade at the same time, the same amount, to maintain balance. Follow original sharpening pattern as shown. Do not sharpen blade to a razor edge, but leave a 1/32" blunt edge. Do not shapen back side of blade. Figure 7.

WARNING! Avoid personal injury. Always block the cutter up to prevent it from falling when the blades and/ or carrier are being serviced.

MAINTAIN CORNER

FOLLOW ORIGINAL PATTERN

1/32"

FIGURE 7

BLADE REMOVAL

Hold the end of blade using heavy leather gloves and remove left hand threaded bolt.

BLADE INSTALLATION

Install washer on blade bolt, insert bolt into blade, insert seal protector washer over blade bolt and then thread bolt into spindle shaft. NOTE: Blade bolt has left hand threads. Tighten blade bolt to 85 ft. lbs. torque. Use heavy leather gloves during tightening process to hold blade and wrench.

GK6072 08/01 | Maintenance Section |

© 2004 Alamo Group Inc.

MAINTENANCE