OPERATION

OPERATION

DRIVELINE LENGTH

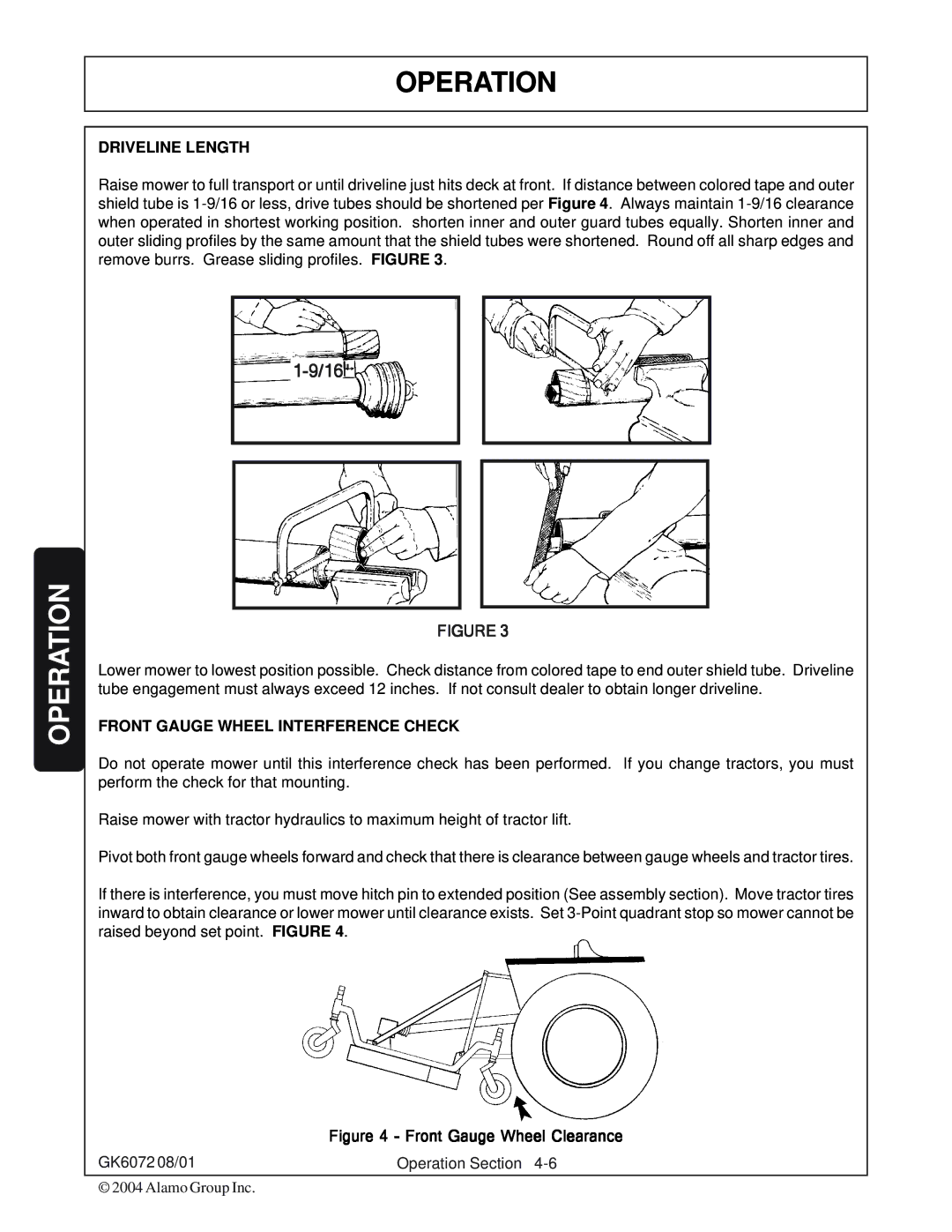

Raise mower to full transport or until driveline just hits deck at front. If distance between colored tape and outer shield tube is

FIGURE 3

Lower mower to lowest position possible. Check distance from colored tape to end outer shield tube. Driveline tube engagement must always exceed 12 inches. If not consult dealer to obtain longer driveline.

FRONT GAUGE WHEEL INTERFERENCE CHECK

Do not operate mower until this interference check has been performed. If you change tractors, you must perform the check for that mounting.

Raise mower with tractor hydraulics to maximum height of tractor lift.

Pivot both front gauge wheels forward and check that there is clearance between gauge wheels and tractor tires.

If there is interference, you must move hitch pin to extended position (See assembly section). Move tractor tires inward to obtain clearance or lower mower until clearance exists. Set

| Figure 4 - Front Gauge Wheel Clearance |

GK6072 08/01 | Operation Section |

© 2004 Alamo Group Inc.