No. 690 Portable Power Drive

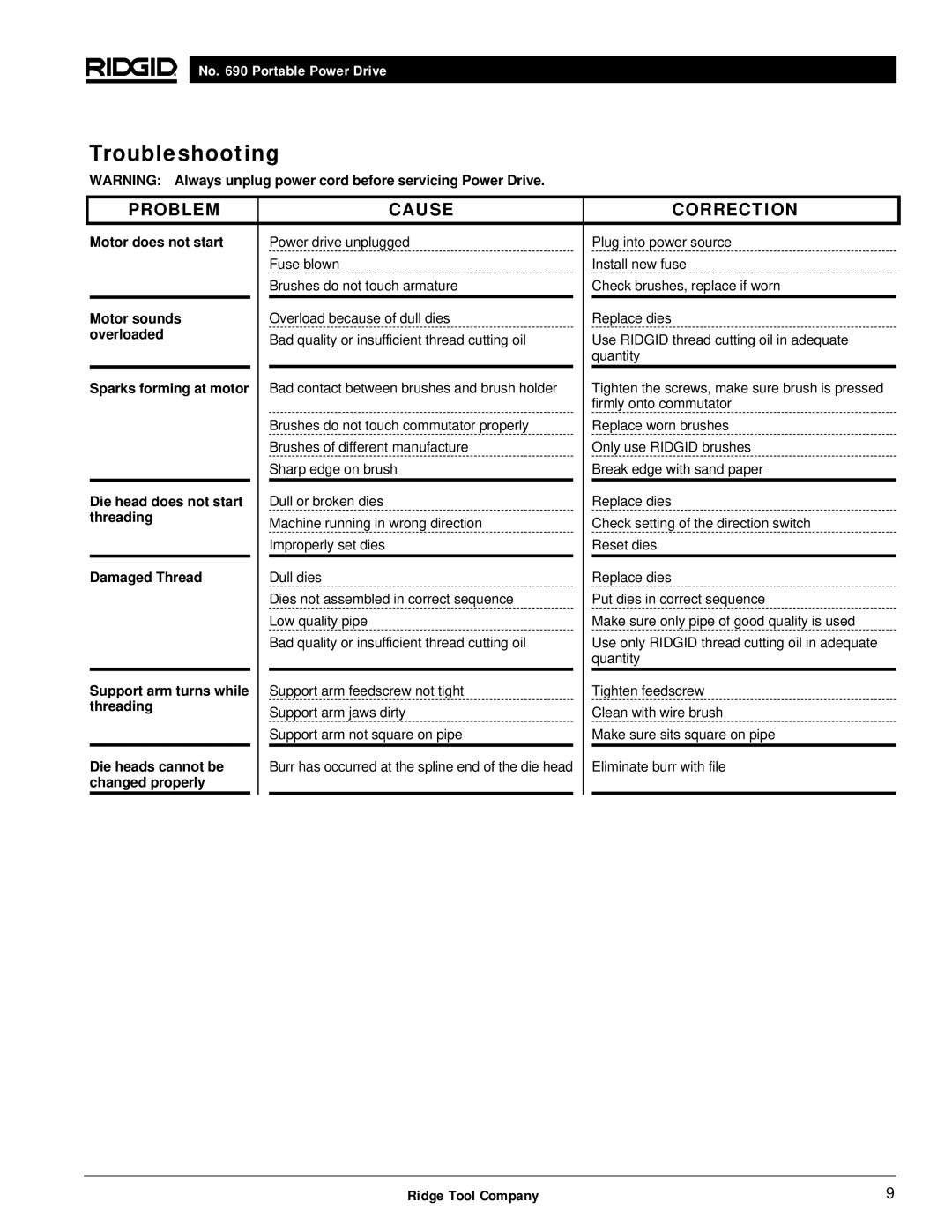

Troubleshooting

WARNING: Always unplug power cord before servicing Power Drive.

PROBLEM |

| CAUSE |

|

| CORRECTION |

| |

|

|

|

|

|

|

|

|

Motor does not start |

| Power drive unplugged |

|

| Plug into power source |

| |

|

|

| Fuse blown |

|

| Install new fuse |

|

|

|

| Brushes do not touch armature |

|

| Check brushes, replace if worn |

|

Motor sounds |

| Overload because of dull dies |

|

| Replace dies |

| |

overloaded |

| Bad quality or insufficient thread cutting oil |

|

| Use RIDGID thread cutting oil in adequate |

| |

|

|

|

|

|

| ||

|

|

|

|

|

| quantity |

|

|

|

|

|

|

|

|

|

Sparks forming at motor |

| Bad contact between brushes and brush holder |

|

| Tighten the screws, make sure brush is pressed |

| |

|

|

|

|

|

| firmly onto commutator |

|

|

|

| Brushes do not touch commutator properly |

|

| Replace worn brushes |

|

|

|

| Brushes of different manufacture |

|

| Only use RIDGID brushes |

|

|

|

| Sharp edge on brush |

|

| Break edge with sand paper |

|

Die head does not start |

| Dull or broken dies |

|

| Replace dies |

| |

threading |

| Machine running in wrong direction |

|

| Check setting of the direction switch |

| |

|

|

|

|

|

| ||

|

|

| Improperly set dies |

|

| Reset dies |

|

Damaged Thread |

| Dull dies |

|

| Replace dies |

| |

|

|

| Dies not assembled in correct sequence |

|

| Put dies in correct sequence |

|

|

|

| Low quality pipe |

|

| Make sure only pipe of good quality is used |

|

|

|

| Bad quality or insufficient thread cutting oil |

|

| Use only RIDGID thread cutting oil in adequate |

|

|

|

|

|

|

| quantity |

|

Support arm turns while |

| Support arm feedscrew not tight |

|

| Tighten feedscrew |

| |

threading |

| Support arm jaws dirty |

|

| Clean with wire brush |

| |

|

|

|

|

|

| ||

|

|

| Support arm not square on pipe |

|

| Make sure sits square on pipe |

|

Die heads cannot be |

| Burr has occurred at the spline end of the die head |

|

| Eliminate burr with file |

| |

changed properly |

|

|

|

|

|

|

|

Ridge Tool Company | 9 |