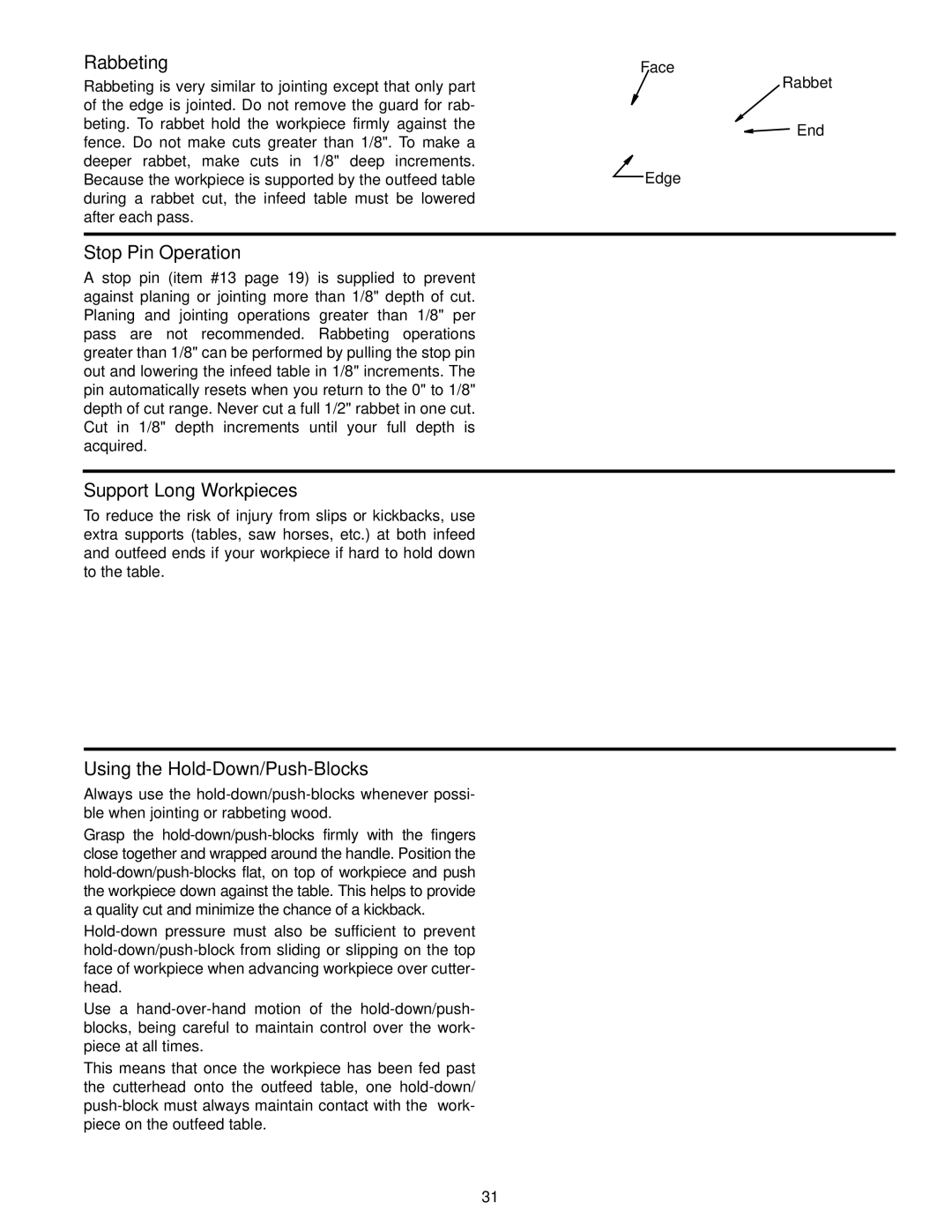

Rabbeting

Rabbeting is very similar to jointing except that only part of the edge is jointed. Do not remove the guard for rab- beting. To rabbet hold the workpiece firmly against the fence. Do not make cuts greater than 1/8". To make a deeper rabbet, make cuts in 1/8" deep increments. Because the workpiece is supported by the outfeed table during a rabbet cut, the infeed table must be lowered after each pass.

Face

Rabbet

End

End

Edge

Stop Pin Operation

A stop pin (item #13 page 19) is supplied to prevent against planing or jointing more than 1/8" depth of cut. Planing and jointing operations greater than 1/8" per pass are not recommended. Rabbeting operations greater than 1/8" can be performed by pulling the stop pin out and lowering the infeed table in 1/8" increments. The pin automatically resets when you return to the 0" to 1/8" depth of cut range. Never cut a full 1/2" rabbet in one cut. Cut in 1/8" depth increments until your full depth is acquired.

Support Long Workpieces

To reduce the risk of injury from slips or kickbacks, use extra supports (tables, saw horses, etc.) at both infeed and outfeed ends if your workpiece if hard to hold down to the table.

Using the Hold-Down/Push-Blocks

Always use the

Grasp the

Use a

This means that once the workpiece has been fed past the cutterhead onto the outfeed table, one

31