5.As machine moves forward and rod handler should push downward on rod with rod guided between thumbs and palms of hands with fingers extended.

WARNING

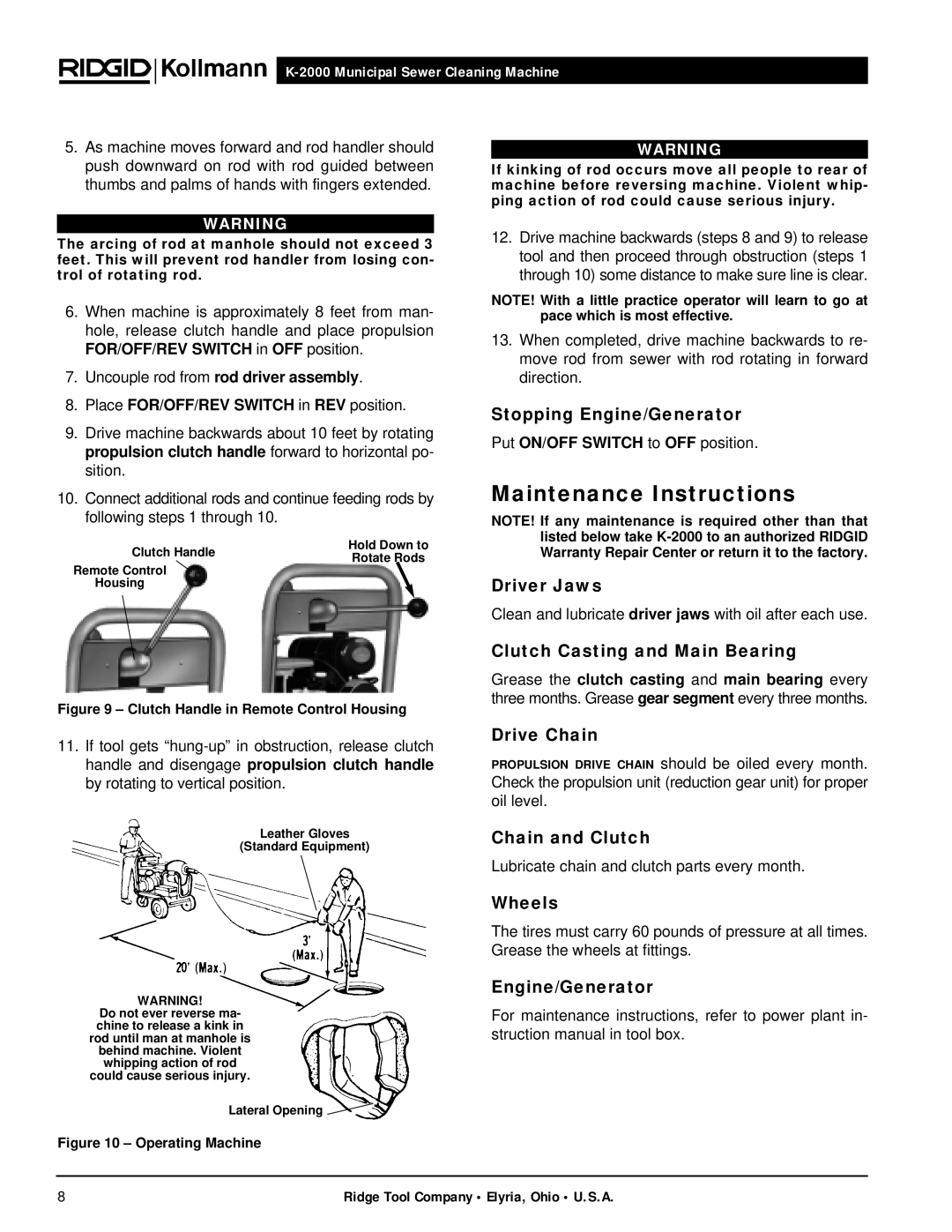

If kinking of rod occurs move all people to rear of machine before reversing machine. Violent whip- ping action of rod could cause serious injury.

WARNING

The arcing of rod at manhole should not exceed 3 feet. This will prevent rod handler from losing con- trol of rotating rod.

6.When machine is approximately 8 feet from man- hole, release clutch handle and place propulsion FOR/OFF/REV SWITCH in OFF position.

7.Uncouple rod from rod driver assembly.

8.Place FOR/OFF/REV SWITCH in REV position.

9.Drive machine backwards about 10 feet by rotating propulsion clutch handle forward to horizontal po- sition.

10.Connect additional rods and continue feeding rods by following steps 1 through 10.

Clutch Handle | Hold Down to | |

Rotate Rods | ||

Remote Control | ||

| ||

Housing |

|

Figure 9 – Clutch Handle in Remote Control Housing

11.If tool gets

Leather Gloves

(Standard Equipment)

WARNING!

Do not ever reverse ma- chine to release a kink in rod until man at manhole is behind machine. Violent whipping action of rod could cause serious injury.

12.Drive machine backwards (steps 8 and 9) to release tool and then proceed through obstruction (steps 1 through 10) some distance to make sure line is clear.

NOTE! With a little practice operator will learn to go at pace which is most effective.

13.When completed, drive machine backwards to re- move rod from sewer with rod rotating in forward direction.

Stopping Engine/Generator

Put ON/OFF SWITCH to OFF position.

Maintenance Instructions

NOTE! If any maintenance is required other than that listed below take

Driver Jaws

Clean and lubricate driver jaws with oil after each use.

Clutch Casting and Main Bearing

Grease the clutch casting and main bearing every three months. Grease gear segment every three months.

Drive Chain

PROPULSION DRIVE CHAIN should be oiled every month. Check the propulsion unit (reduction gear unit) for proper oil level.

Chain and Clutch

Lubricate chain and clutch parts every month.

Wheels

The tires must carry 60 pounds of pressure at all times. Grease the wheels at fittings.

Engine/Generator

For maintenance instructions, refer to power plant in- struction manual in tool box.

Lateral Opening ![]()

Figure 10 – Operating Machine

8 | Ridge Tool Company • Elyria, Ohio • U.S.A. |