Description, Specifications and Standard Equipment

Description

The RIDGID/Kollmann

Specifications

Capacity |

|

Cable | 4″ through 12″ lines to 250′ |

Rod | 24″ mains through 500′ |

Dual Speed Drive |

|

Sectional Cable | 250 rpm |

Solid Rod | 60 rpm |

Clutches |

|

for driving Cable or Rods | |

Propulsion Clutch | for propelling machine when |

| using Rods |

Switches |

|

Rod & Cable | FOR/OFF/REV SWITCH |

| |

Propulsion | FOR/OFF/REV SWITCH |

| |

Manual |

|

Cable Counter | for Cable or Rods |

Stationary |

|

Positioner Arm | lowers manually to raise Front |

| Wheels when using Cable |

Engine/Generator | 1500 watt, |

| 60 Hz., Engine 3.8 h.p., 3600 |

| rpm (Instruction Manual in |

| Tool Box) |

| NOTE! Use only leaded or |

| |

| engine. |

Motors |

|

For Spinning Cable |

|

and Rod | Universal, 1/2 h.p., 115 volt, |

| 60 Hz. |

For propulsion drive | 1/6 h.p., |

| phase, 60 Hz., gear motor |

Length | 44″ |

Width | 31″ |

Height | 361/2″ |

Weight with |

|

Standard Equipment | 393 lbs. |

Standard Equipment

Rod Driver | |

Tool Adapter | |

Tool Box | Contains 1 Clutch Handle and |

| 1 quart of engine oil. |

Glove (L.H.) | |

Glove (R.H.) | |

Rod Turner |

Accessories

See Ridge Tool Main Product Catalog for machine ac- cessories.

Operating Instructions

Preparing Machine for Cable Operation

1.Position sewer cleaning machine about two feet from manhole or other inlet.

2.Engage drive clutch and lock rear wheel (Figure 9) in straight position for stability. Unplug gear motor from engine/generator (Figure 3).

3.Release two latches (Figure 3) and remove guard on front of machine.

4.Pull ratchet knob (Figure 3) on motor table and raise table. Lock in highest position by giving ratchet knob

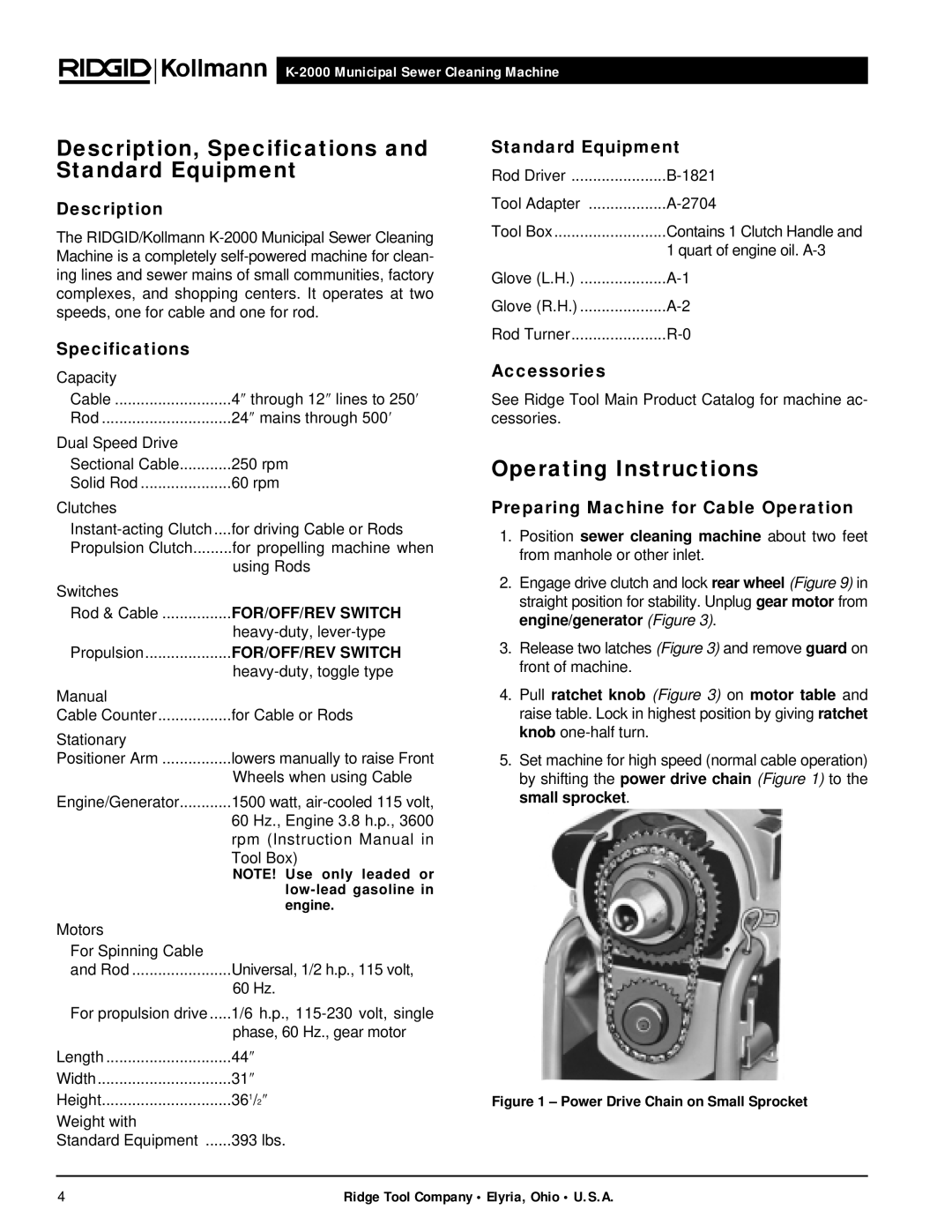

5.Set machine for high speed (normal cable operation) by shifting the power drive chain (Figure 1) to the small sprocket.

Figure 1 – Power Drive Chain on Small Sprocket

4 | Ridge Tool Company • Elyria, Ohio • U.S.A. |