1.Belt Guard. The belt guard encloses the pulleys and drive belt. It protects the user from moving parts and directs cooling air to the compressor pump.

2.Air Filter. The air filter keeps dirt and debris from entering the compressor pump and reduces compressor noise.

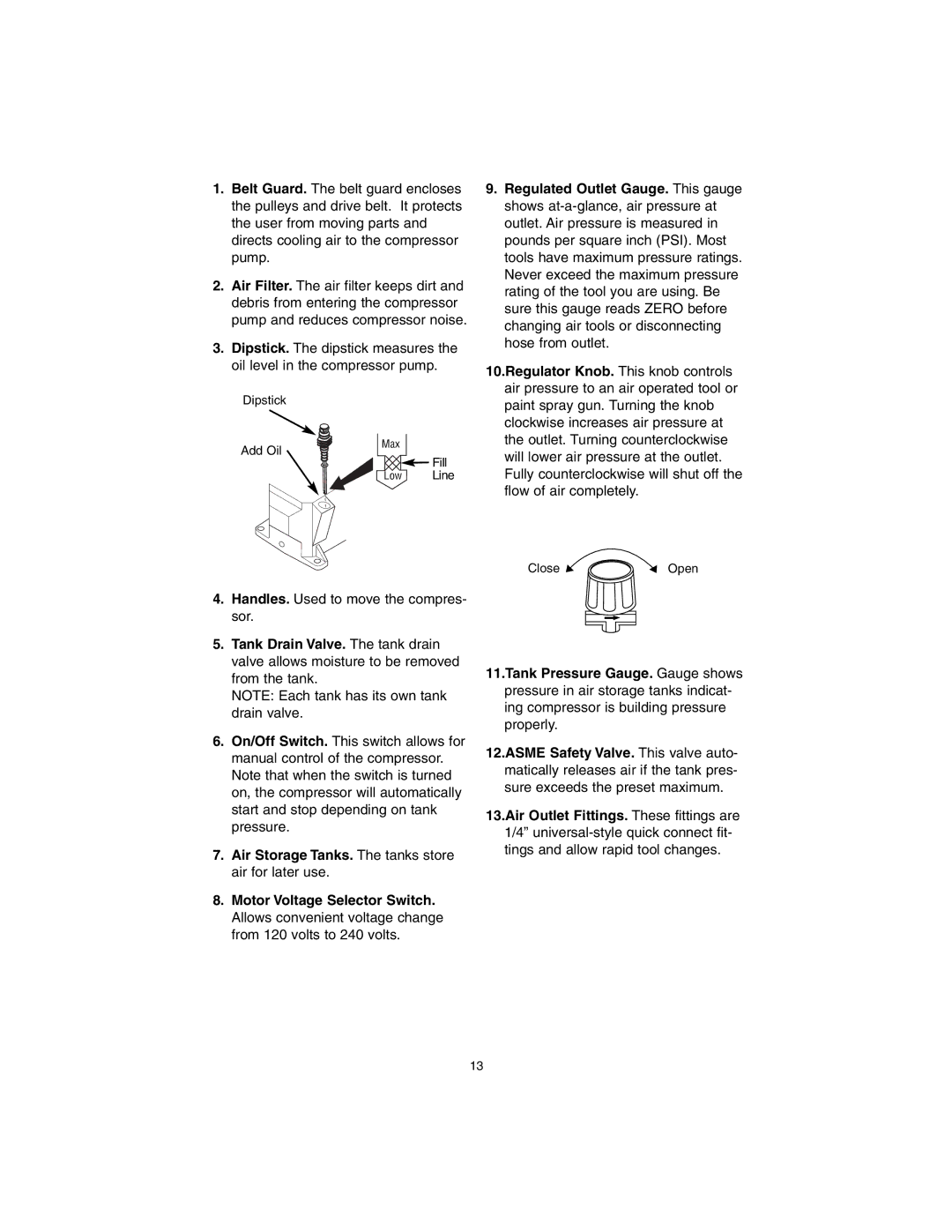

3.Dipstick. The dipstick measures the oil level in the compressor pump.

Dipstick

9.Regulated Outlet Gauge. This gauge shows

10.Regulator Knob. This knob controls air pressure to an air operated tool or paint spray gun. Turning the knob clockwise increases air pressure at the outlet. Turning counterclockwise

Add Oil

Max

![]()

![]() Fill

Fill

Low Line

will lower air pressure at the outlet. Fully counterclockwise will shut off the flow of air completely.

Close ![]()

![]()

![]() Open

Open

4.Handles. Used to move the compres-

sor.

5.Tank Drain Valve. The tank drain valve allows moisture to be removed from the tank.

NOTE: Each tank has its own tank drain valve.

6.On/Off Switch. This switch allows for manual control of the compressor. Note that when the switch is turned on, the compressor will automatically start and stop depending on tank pressure.

7.Air Storage Tanks. The tanks store air for later use.

8.Motor Voltage Selector Switch. Allows convenient voltage change from 120 volts to 240 volts.

11.Tank Pressure Gauge. Gauge shows pressure in air storage tanks indicat- ing compressor is building pressure properly.

12.ASME Safety Valve. This valve auto- matically releases air if the tank pres- sure exceeds the preset maximum.

13.Air Outlet Fittings. These fittings are 1/4”

13